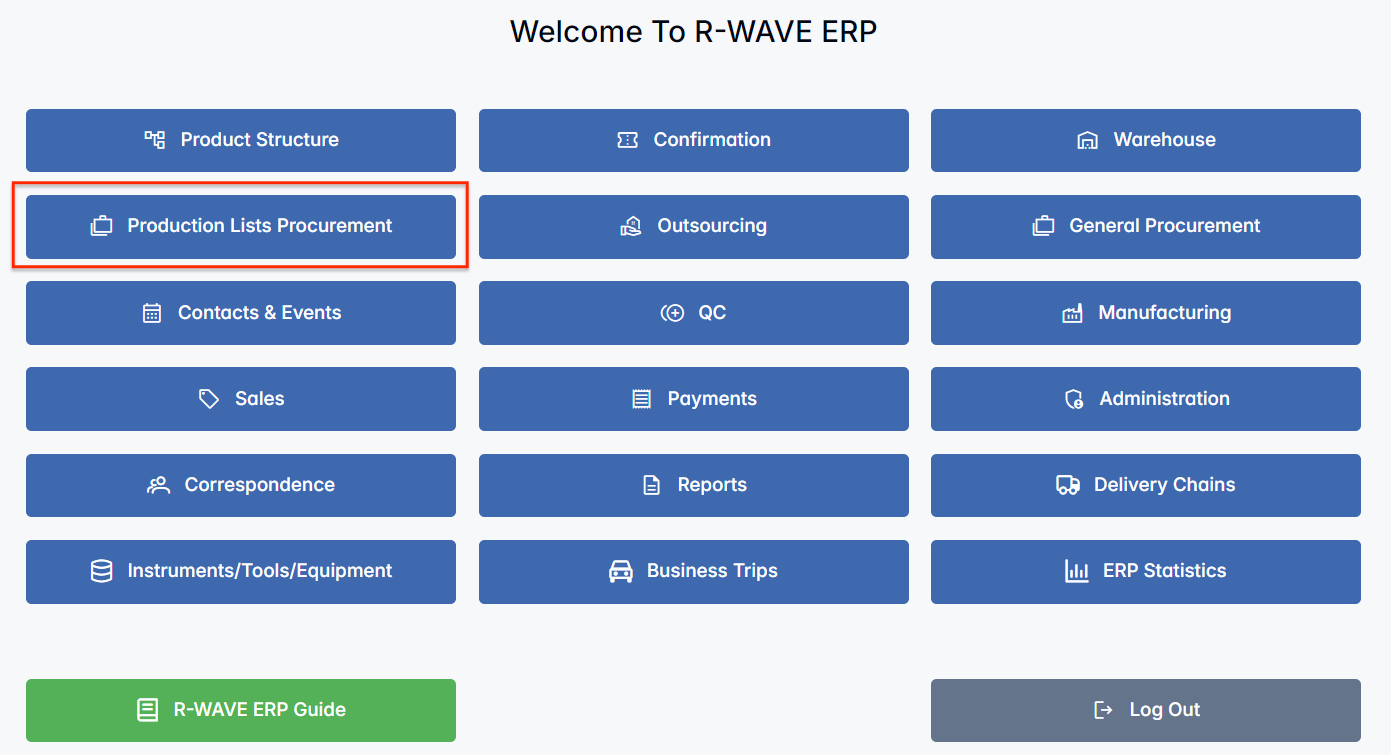

Production Lists Procurement Module

The Production Lists Procurement module in R-Wave ERP is designed to manage purchasing processes automatically generated from production plans. Unlike manual procurement, this module streamlines the supply chain by converting material shortages from production lists directly into procurement requests, ensuring just-in-time delivery and production continuity.

Procurement managers can review and group these auto-generated requests into procurement chains, assign suppliers, manage order quantities, and follow the entire lifecycle of a purchase — from initial request to payment and delivery — all within a structured interface optimized for production-driven operations.

R-WAVE ERP Guide

R-WAVE ERP Guide

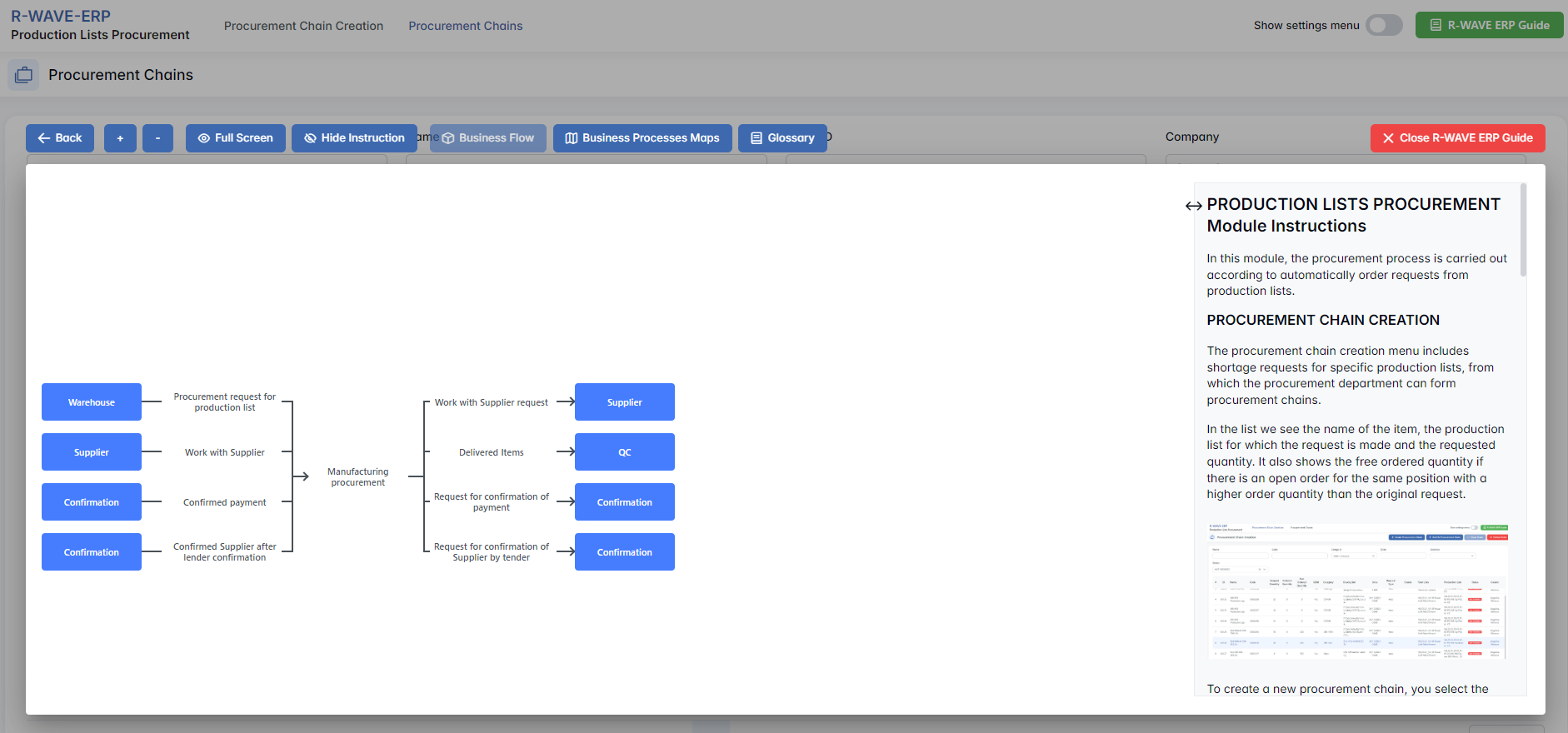

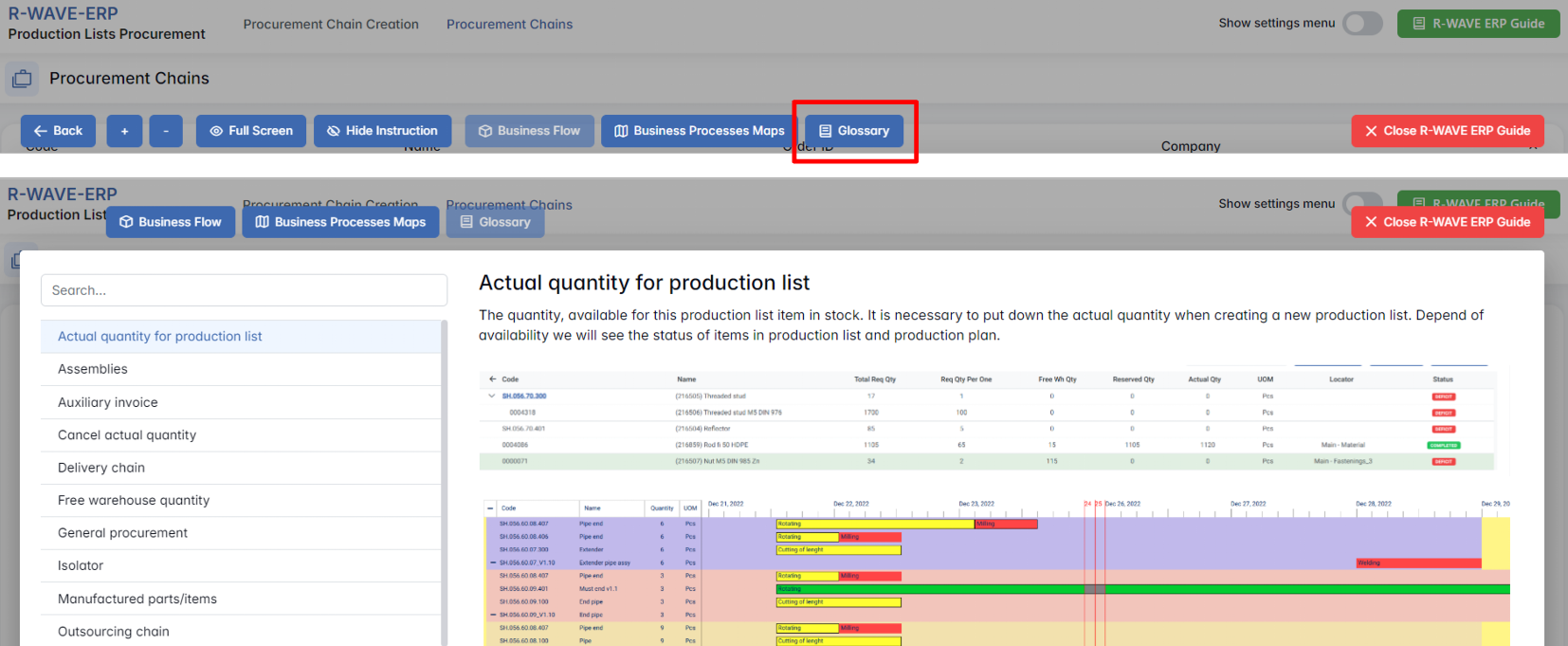

To support user navigation and clarity, R-Wave ERP includes a built-in contextual help system in the form of a pop-up guide window. This feature is available across different modules, including Production Lists Procurement, and is designed to help users understand where they are in the system and how to use the current section effectively.

Purpose

The ERP Guide window helps users by:

- Showing where you are within the system (module context and current section).

- Providing a visual schema of your company’s business flow, helping you understand how the current module fits into the larger operational structure.

- Offering a quick-reference instruction panel with the main actions and functions available in the current tab (e.g., creating companies, filtering, scheduling events).

Layout and Content

When opened, the ERP Guide window is divided into two main areas:

- Left Side — Business Flow Map

This section displays a structured diagram of your company's processes and how the current module connects to others (e.g., CRM, Procurement, Sales, HR). It visually highlights your current position in the overall ERP environment. - Right Side — Functional Overview

Provides a concise, bullet-style instruction list describing the key operations available in the current module/tab.

Top Bar Options

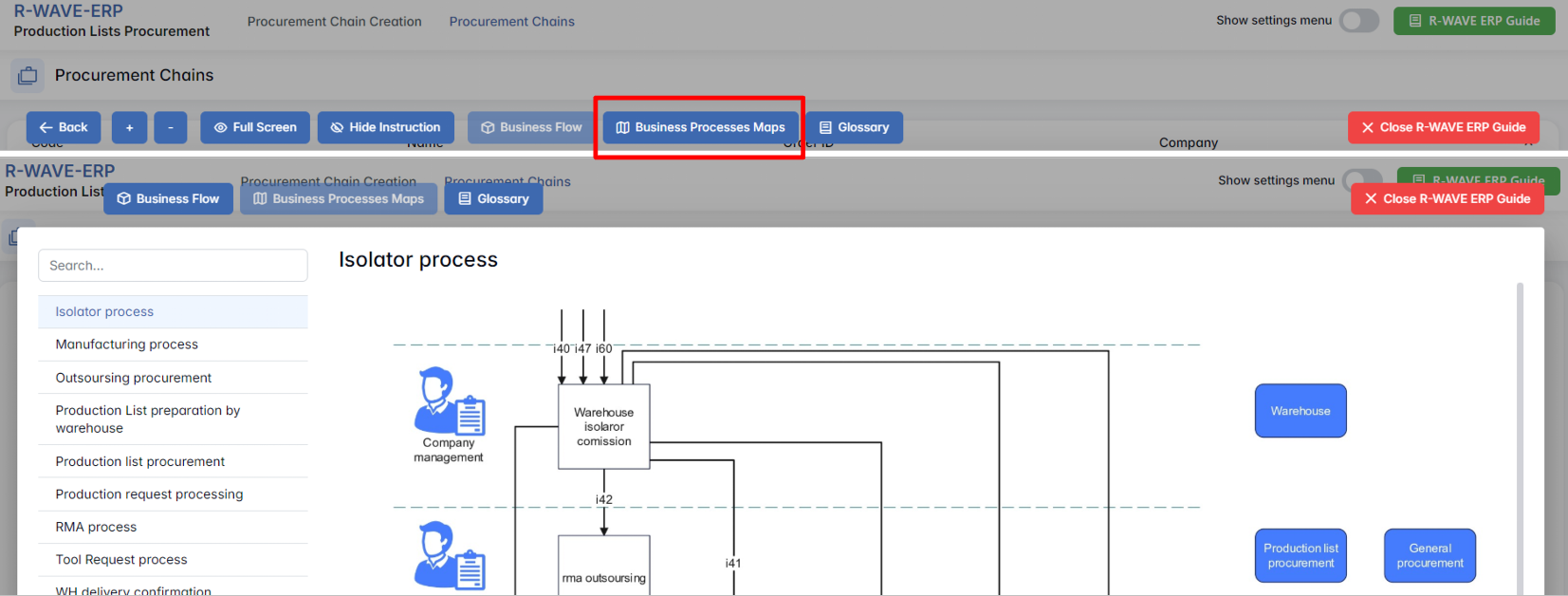

At the top of the ERP Guide window, you’ll find two optional tools for deeper understanding:

- Business Processes Maps – Opens a full interactive view of your organization’s process structure.

- Glossary – Provides definitions and descriptions of key terms and field labels used in the ERP interface.

The ERP Guide window can usually be opened via a dedicated icon or help button (often located in the upper right corner of the screen). It is non-intrusive and can be closed or reopened as needed, allowing users to stay focused without losing their place.

Production Lists Module Overview

The Production Lists module provides users with a structured interface to manage all non-automated purchasing workflows, typically initiated by internal departments through manual requests. It is particularly suited for indirect, or operational purchases that fall outside standard production procurement. The module acts as a bridge between internal demand and external suppliers, enabling procurement teams to handle diverse purchasing scenarios with flexibility and control.

The module is divided into two main sections, accessible via the top menu:

1. Procurement Requests

Allows to review shortage requests from production lists and convert them into actionable procurement chains by selecting suppliers and adjusting quantities.

2. Procurement Chains

Displays the full order lifecycle: supplier details, invoices, deliveries, payments, and attached documentation.

The system opens by default on the Procurement Chains page for fast access to ongoing orders and invoice management.

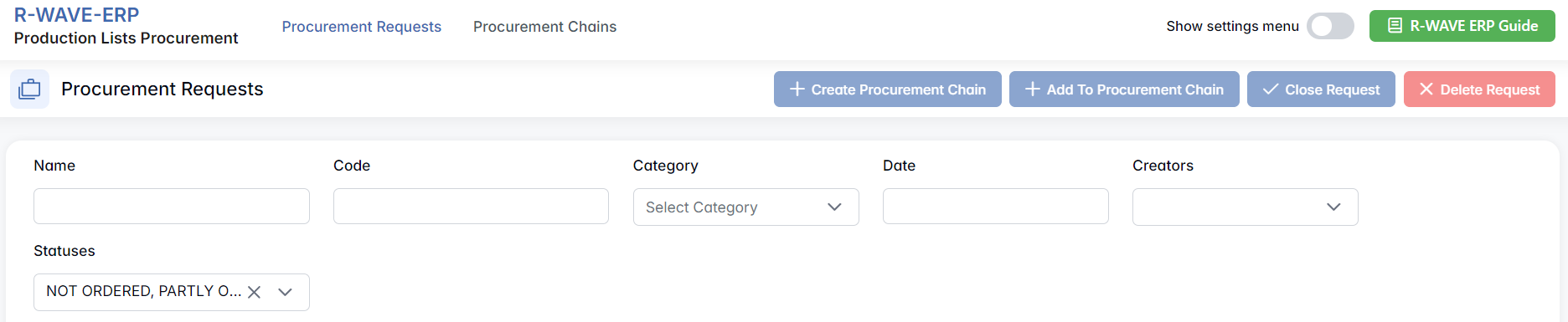

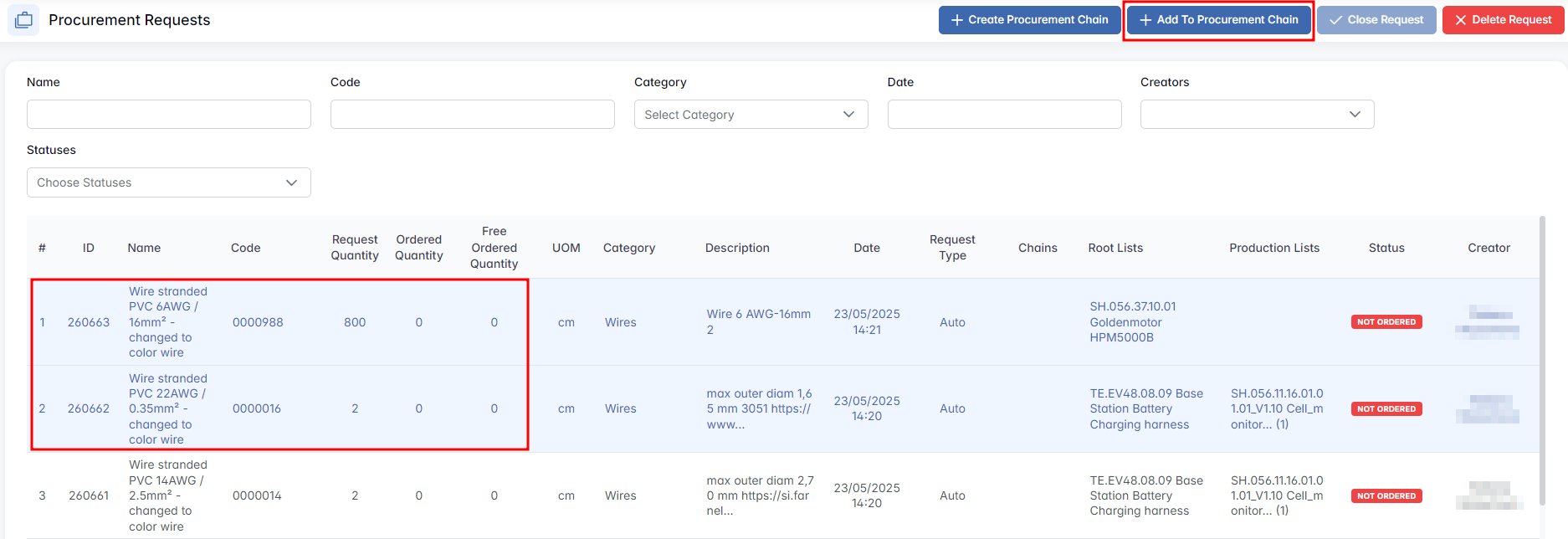

Procurement Requests

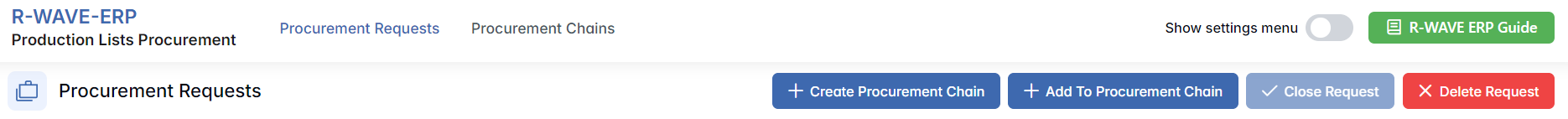

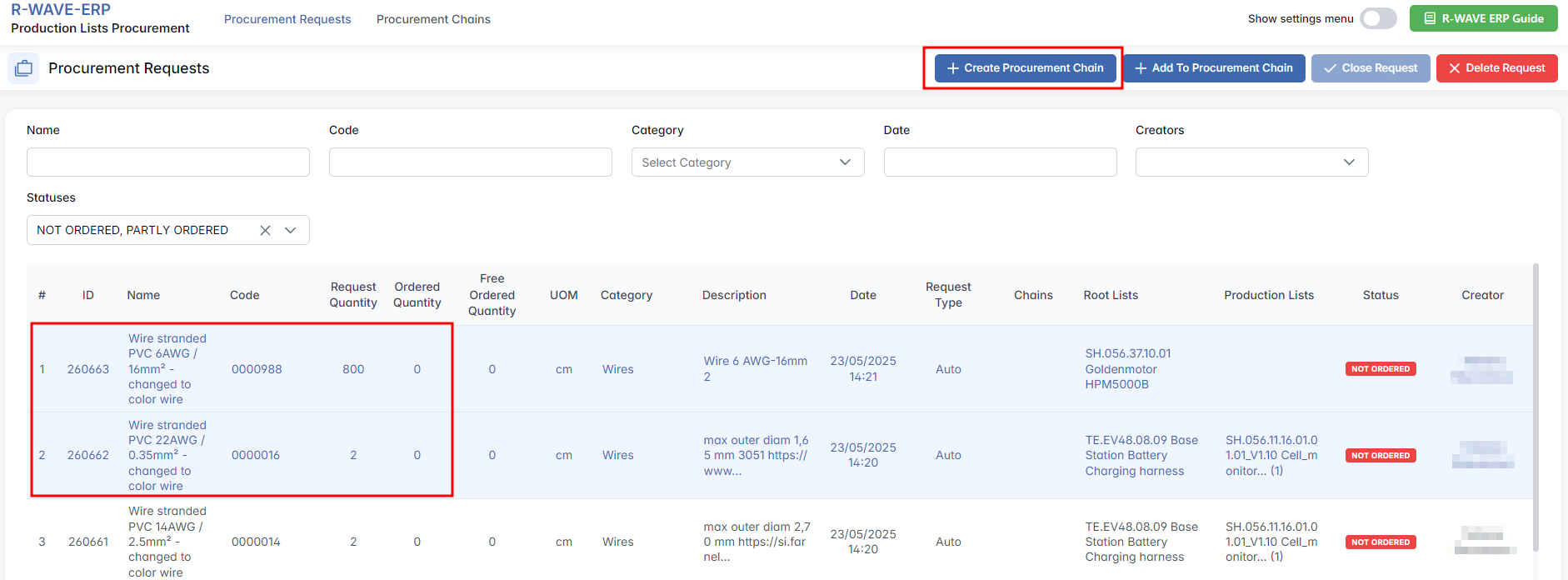

Procurement Requests

The Procurement Requests section is a dedicated space where auto-generated procurement requests — based on shortages in production lists — are collected and managed. These requests can be grouped and assigned to procurement chains, where a supplier is selected and the required quantities are finalized.

---

Filter Tab Overview

The filter tab allows users to narrow down request entries based on several parameters:

- Name – Text input to search for specific item names.

- Code – Unique material code identifier.

- Category – A hierarchical tree of categories with multiple selection via checkboxes (e.g., fasteners, connectors, rods, sensors).

- Date – Filter by creation date of the request.

- Creators – Multi-select dropdown to filter requests by the individuals who created them.

- Statuses – Allows filtering by procurement progress:

- NOT ORDERED

- PARTLY ORDERED

- ORDERED

These filters support dynamic data exploration and decision-making by helping teams focus on outstanding or urgent items.

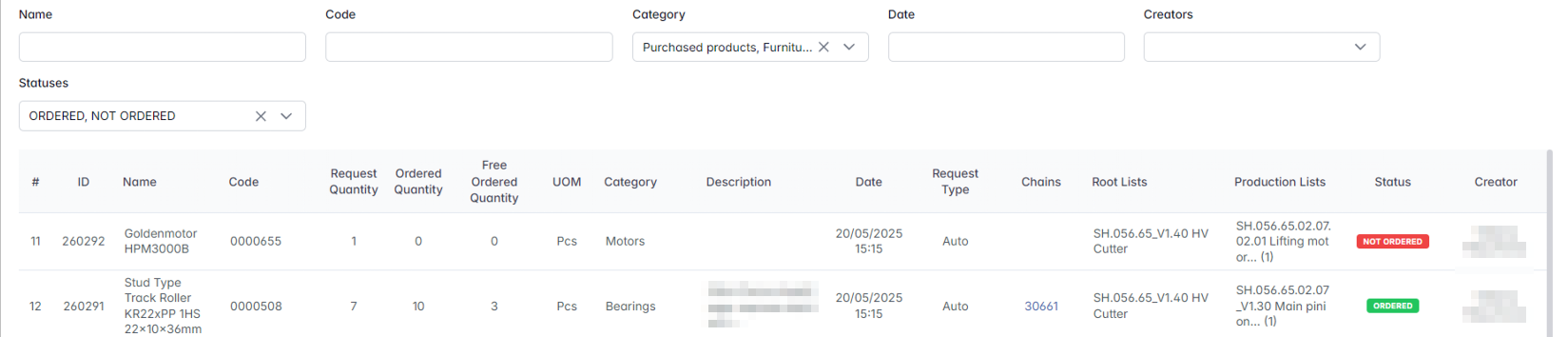

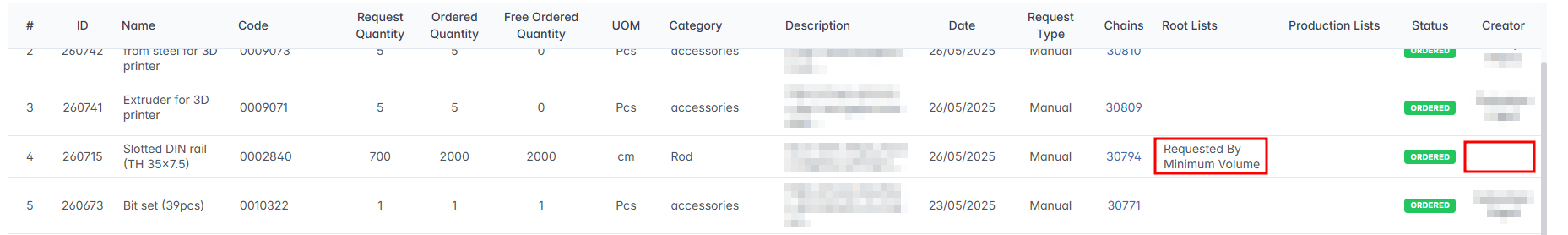

Data Table Overview

Below the filter tab, users find a detailed table containing procurement request records. Each row represents an individual material request with full contextual and quantitative data, including:

| Column | Description |

|---|---|

| ID | Unique identifier of the request. |

| Name | Material or item name. |

| Code | Internal code for the item. |

| Request Quantity | The total quantity of material originally requested. |

| Ordered Quantity | Quantity that has already been ordered. |

| Free Ordered Quantity | The excess quantity that was ordered beyond the required amount. |

| UOM | Unit of measure (e.g., Pcs, cm, cm²). |

| Category | Classification group, selected from a predefined list. |

| Description | Free text or link with detailed specifications or supplier references. |

| Date | The creation date of the request. |

| Request Type | Source of the request: Manual (user-created or triggered by min. stock), Auto (generated automatically based on the items listed in the Production List) or Tool Request (from tool requisition). |

| Chains | Associated procurement chains (if already assigned). |

| Root Lists / Production Lists | Additional lists or production plans linked to the item. |

| Status | Current status in the procurement process (NOT ORDERED, PARTLY ORDERED, ORDERED). |

| Creator | The person responsible for creating the request. |

Filter Behavior and System Feedback

When applying filters in the Production Lists Procurement module, users might receive error messages if certain conditions aren't met.

e.g.:If user applies only Status: ORDERED without additional filters, the system returns: 400: ["At least one additional filter parameter must be passed along with the status 'ORDERED'."]

This enforces better-defined filtering criteria and ensures efficient data retrieval.

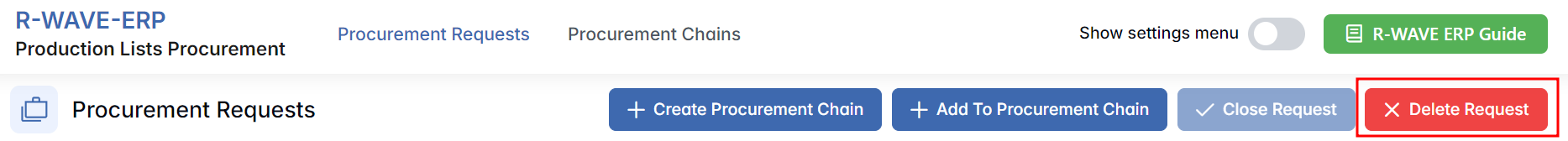

Action Buttons Behavior

Below the filter tab, the following action buttons are available:

- + Create Procurement Chain

- + Add To Procurement Chain

- Close Request

- Delete Request

These buttons are only active when one or more rows are selected from the request table. Their availability depends on the status of the selected records.

Behavior by Record Status

| Selected Record Status | Active Buttons |

|---|---|

| Ordered | None – all buttons remain disabled |

| Partly Ordered (1+ selected) | All except Delete Request |

| Not Ordered (1+ selected) | All except Close Request |

| Mixed: Not Ordered + Partly Ordered (1+ selected) | All except Close Request and Delete Request |

Request Type Specifics

Some requests are created automatically when items reach minimum volume thresholds.

These are labeled as: Requested by minimum volume

- The creator field is empty, because these records appear without manual user initiation

Procurement Chain Navigation

For items in Ordered or Partly Ordered status:

There, detailed information is shown: Order number, Ordered items, Payments, and other additional procurement details.

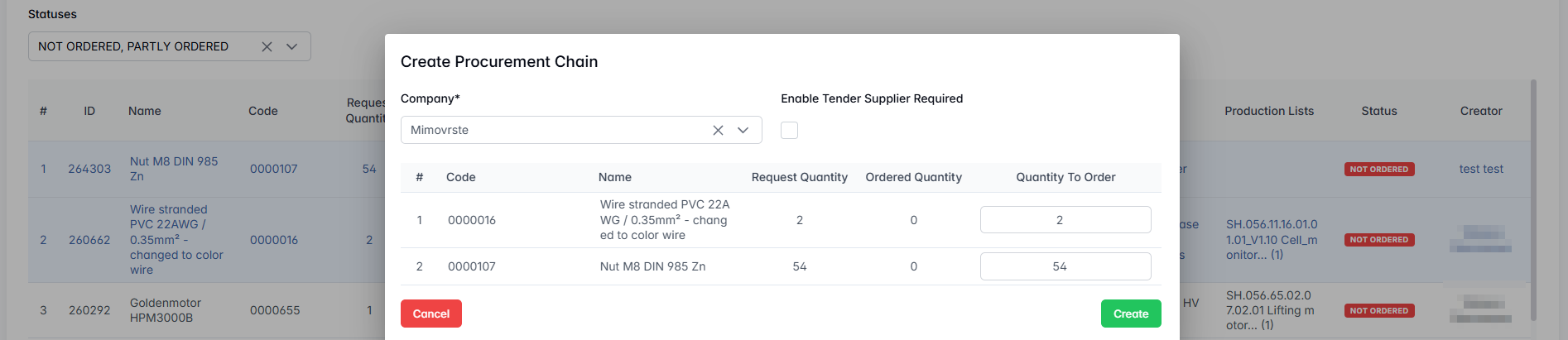

Creating a Procurement Chain

To initiate a procurement process in the R-Wave ERP system, the first step is to select the relevant procurement request(s). These are the material or tool needs that require supplier fulfillment.

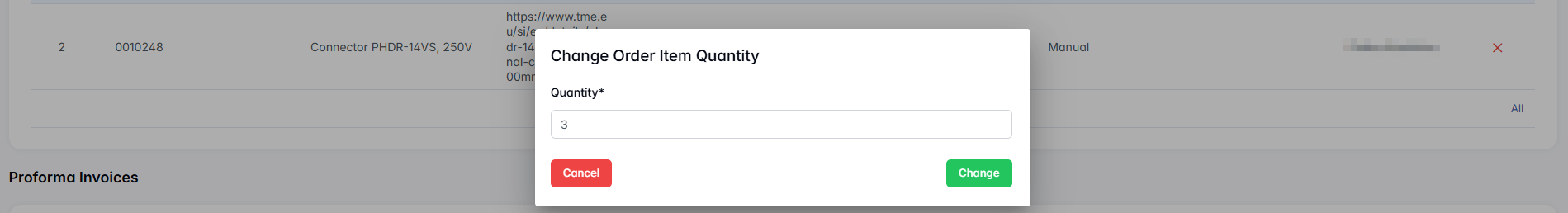

Once you've selected the appropriate request rows, click the + Create Procurement Chain button. This will open a modal window containing the creation form. In this form:

- Company must be selected unless the "Enable tender supplier required" checkbox is checked (used when a supplier isn’t yet chosen).

- Request Quantity — Quantity initially requested.

- Ordered Quantity — Quantity already ordered (if any).

- Quantity To Order — Editable field where the user specifies the actual amount to be ordered in this chain.

Note: The Quantity To Order can exceed the original request if necessary.

After clicking Create, the system will generate the procurement chain and redirect you to the newly created Order page under the Procurement Chains section.

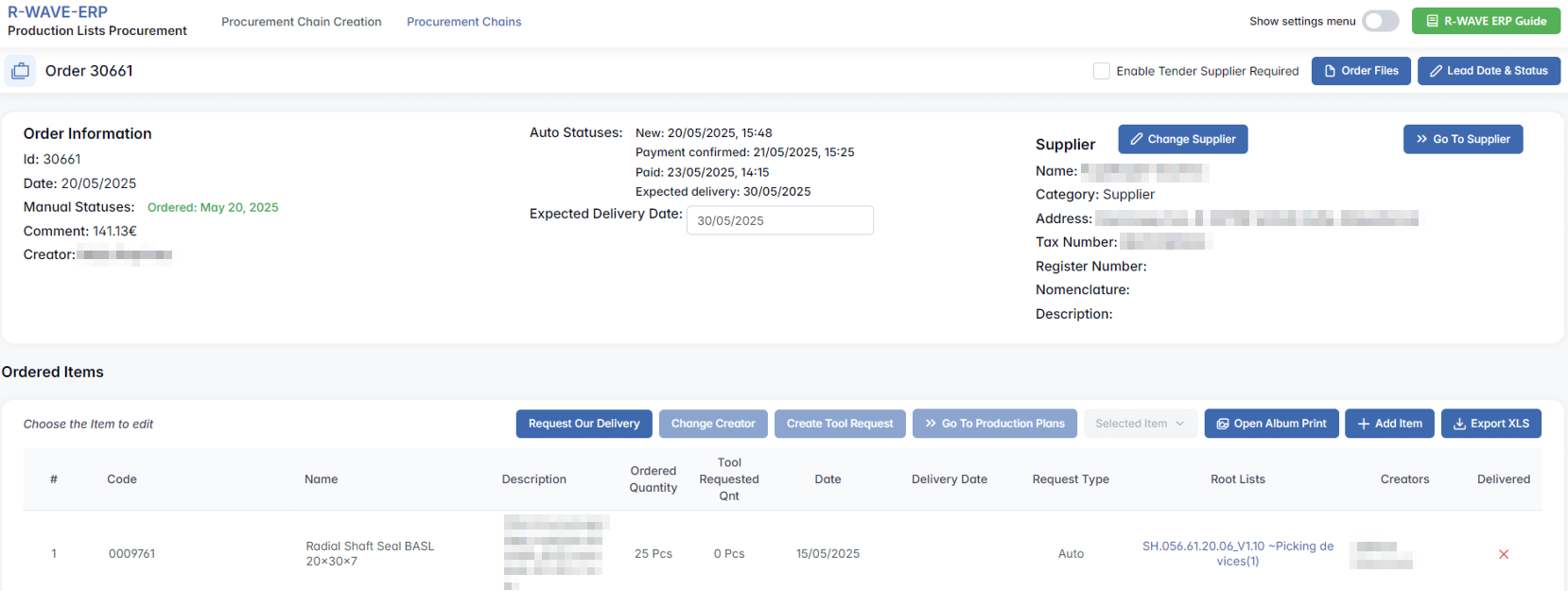

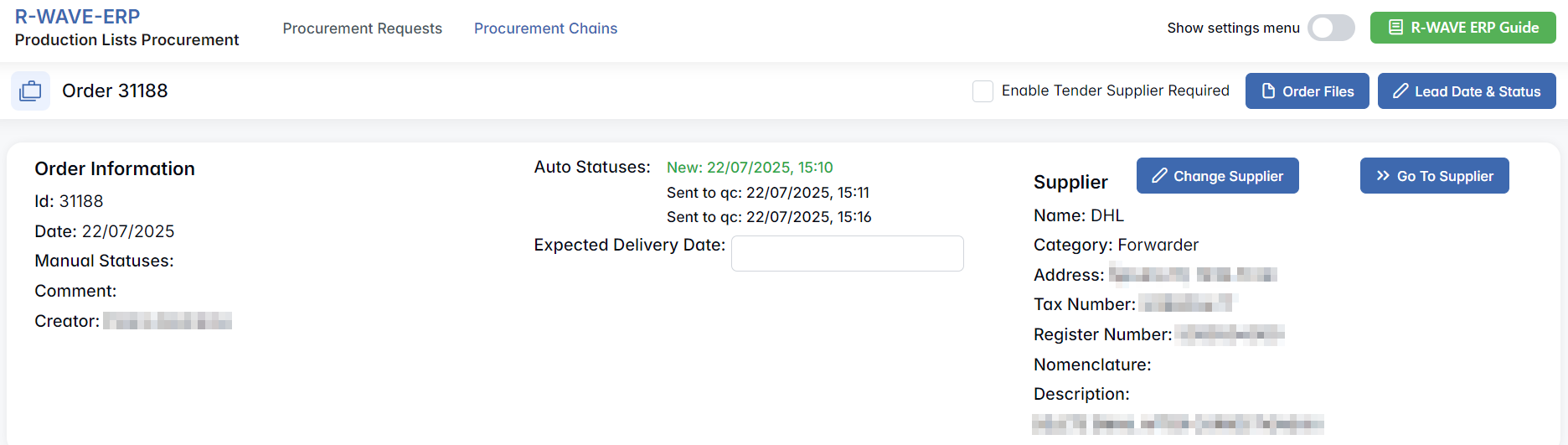

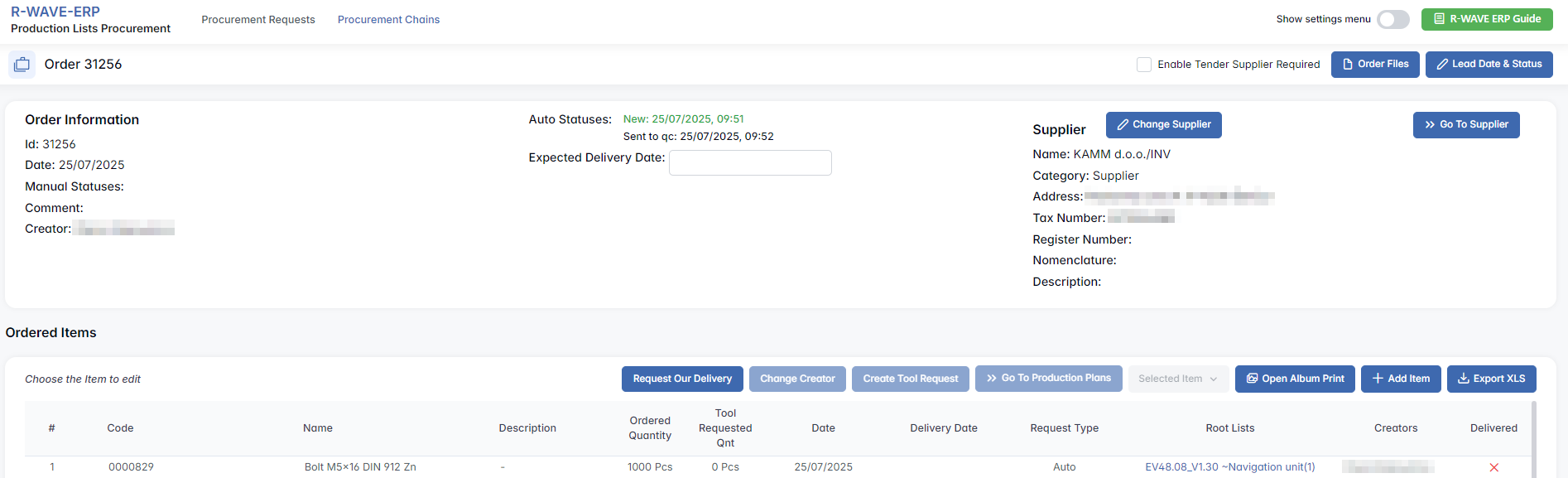

Order Page – Overview

The Order page is divided into several tabs. The top section includes the Order Information:

- You can modify the Purchase Category, set the Expected Delivery Date, or review the Supplier.

- Clicking Go to Supplier opens the supplier profile.

- You can enable the Tender Supplier option if no supplier is defined yet.

- You may also upload files relevant to the chain or view existing ones.

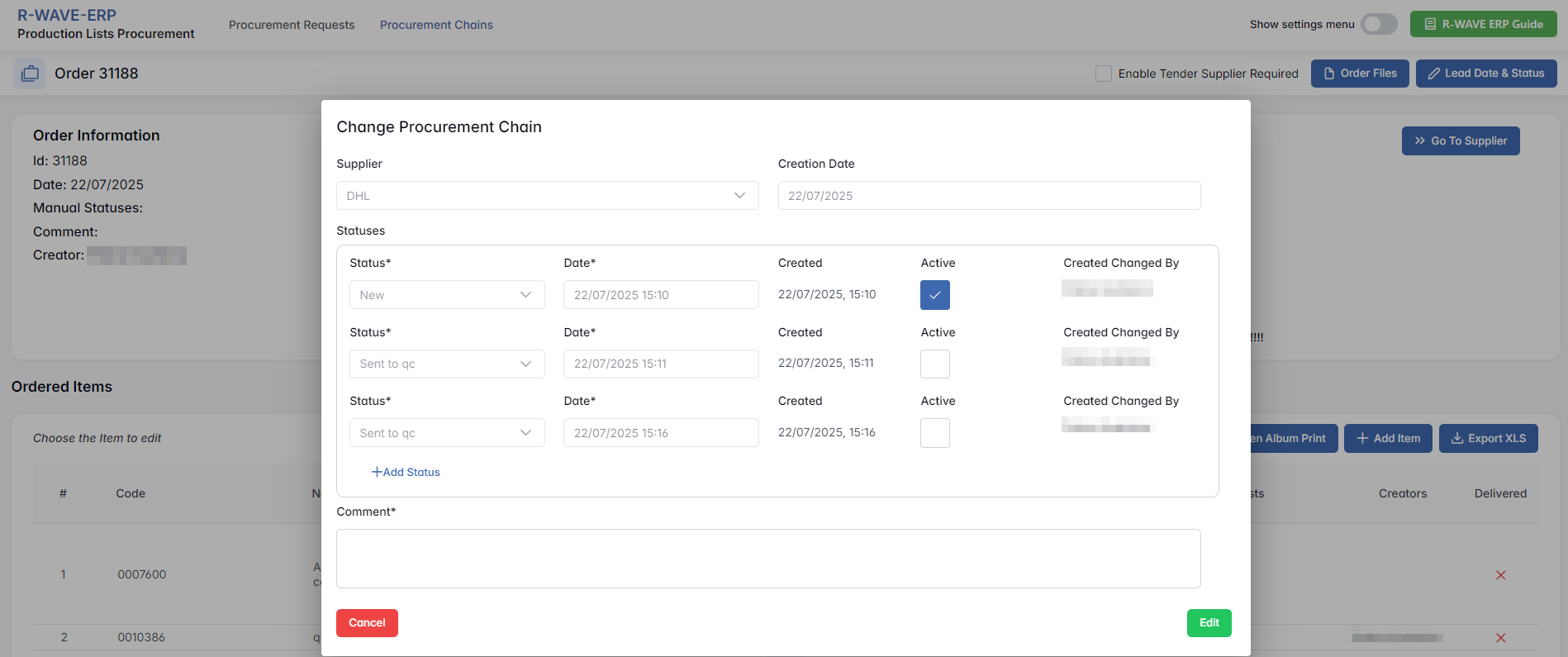

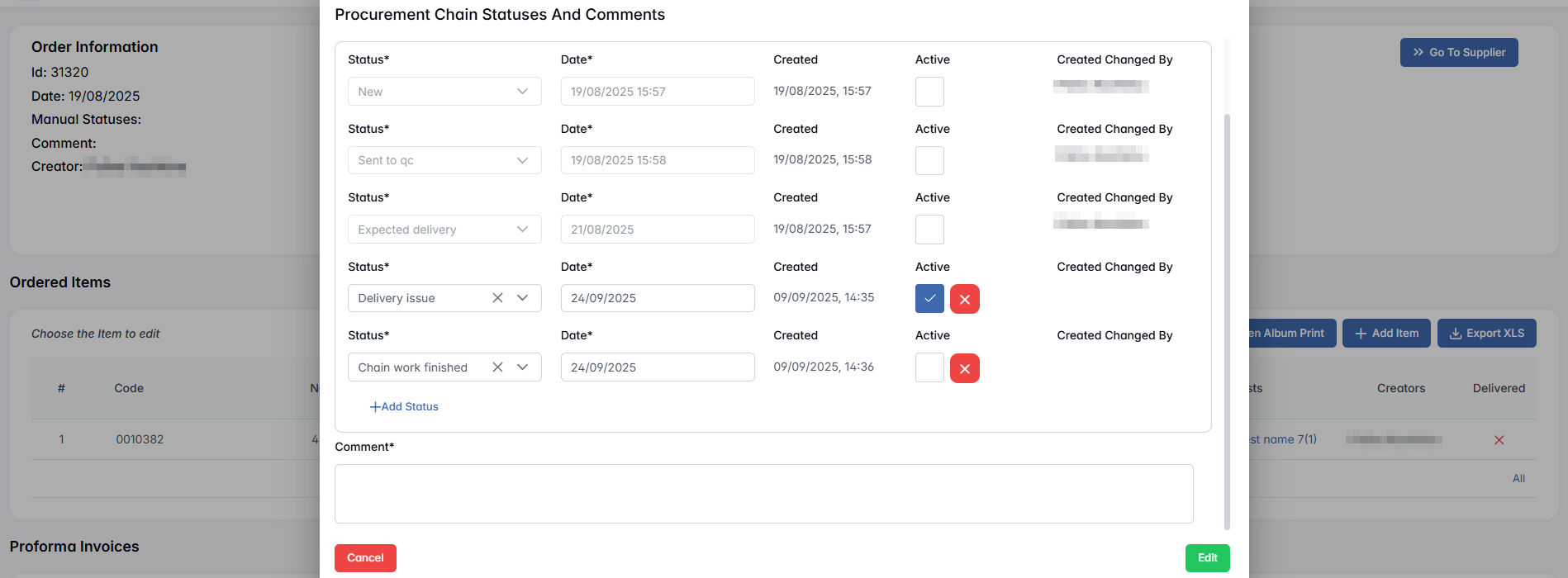

The Lead Date & Status button opens a modal where you can track or update the progress of the chain:

- You can add multiple statuses, but only one can be marked as Active at a time.

- The Comment field is optional.

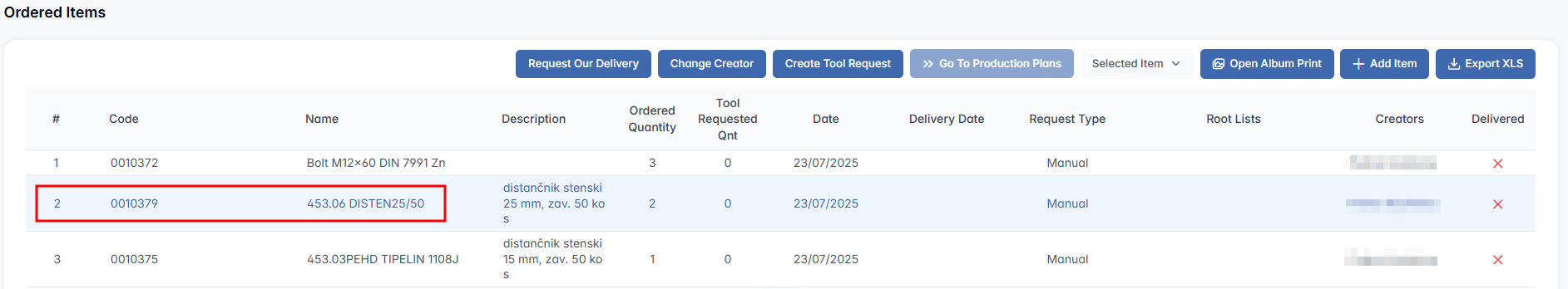

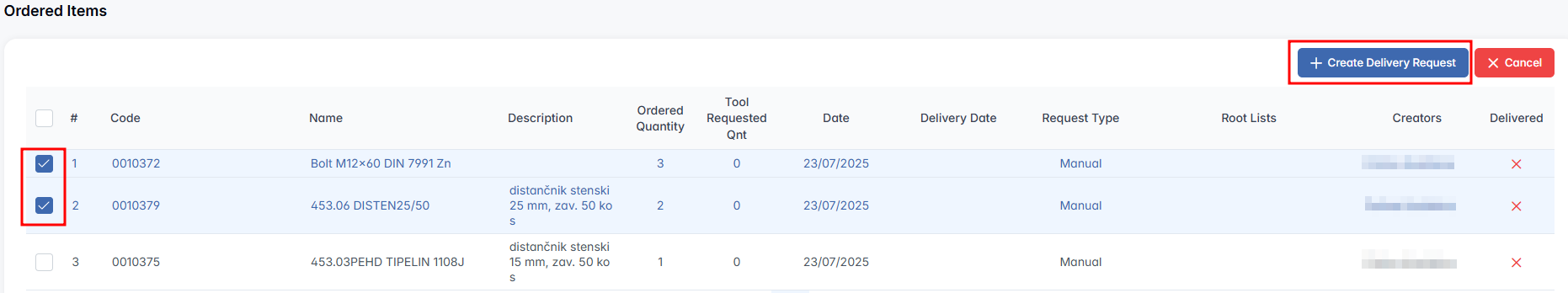

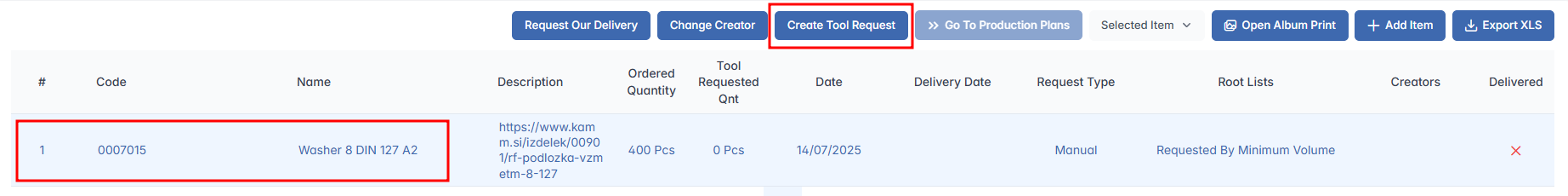

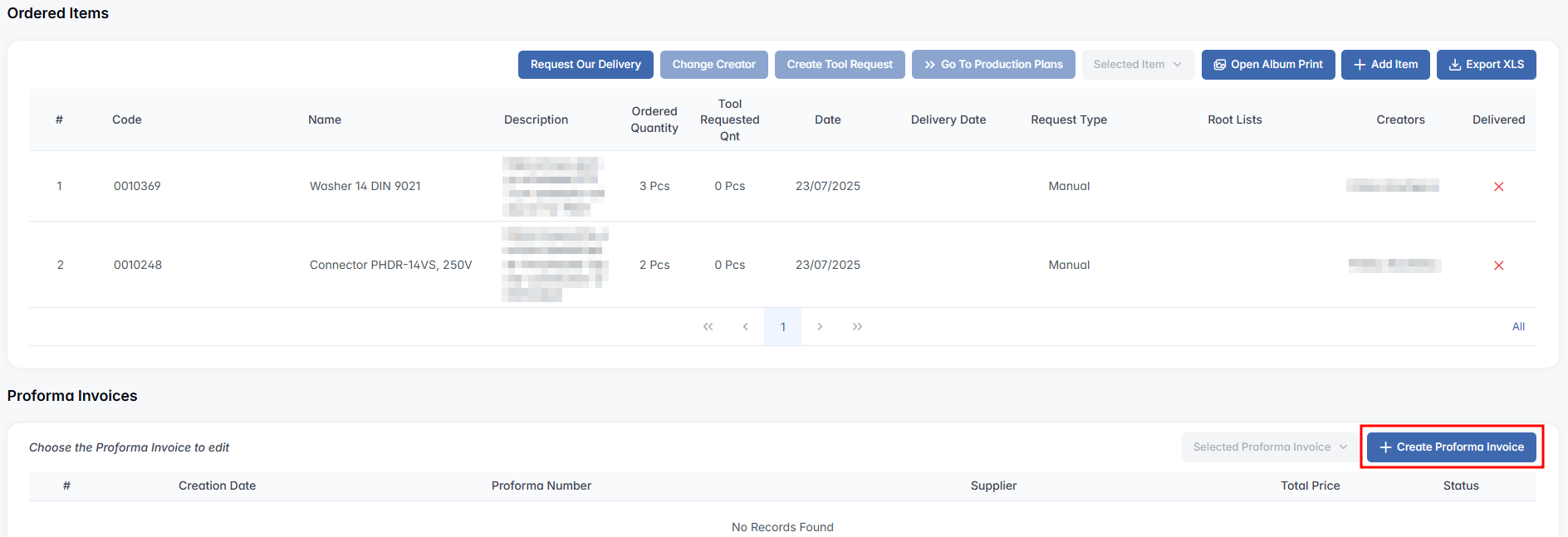

Ordered Items Section

This section displays all items requested within this chain. Several key functions are available:

- Request Our Delivery:

This action is used when a supplier informs that the ordered item is ready for pickup, and the delivery will be arranged internally — not through an external delivery service. By selecting the relevant items and clicking Request Our Delivery, a pickup request is generated for the warehouse team (Warehouse module > Delivery Requests > Ordered Items Delivery). This informs them that they need to collect the item directly from the supplier.

- Change Creator: Assigns a different creator to the selected item.

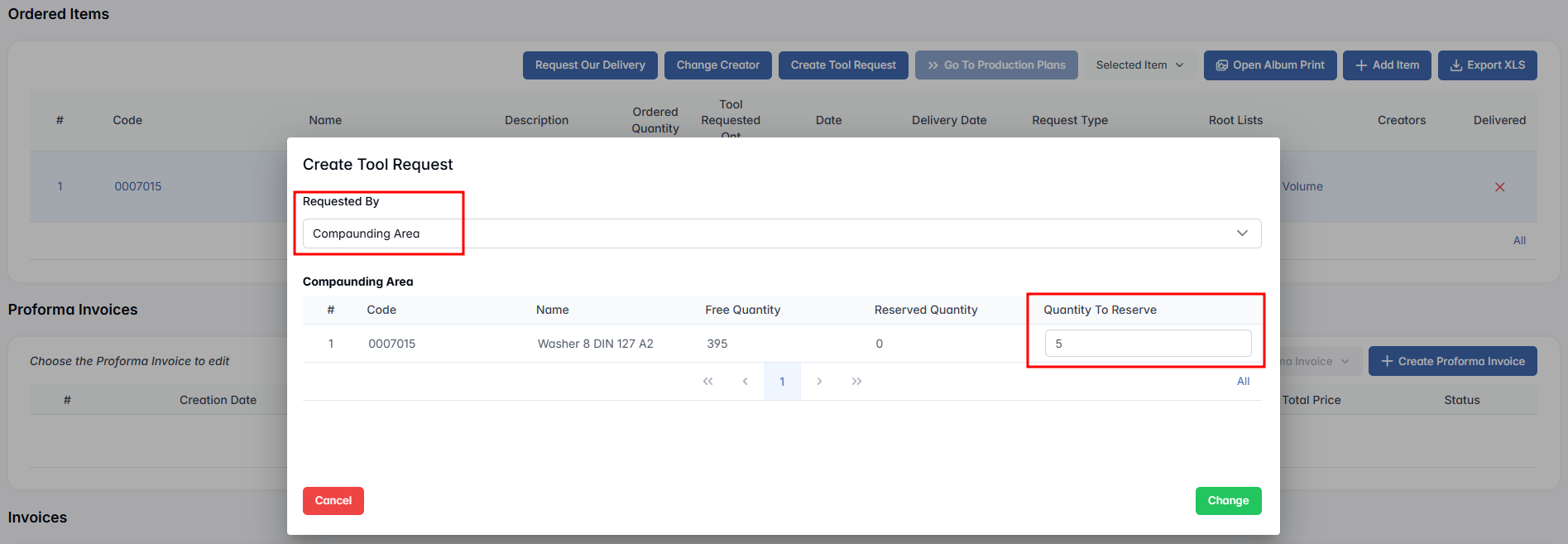

- Create Tool Request: Generates a tool/material request to internal departments.

This function allows the procurement team to create an internal tool or material request directly during the procurement process when a free ordered quantity is available. It is used when part of the ordered items is intended for internal use, ensuring that such usage is properly registered and managed through the formal tool request process.

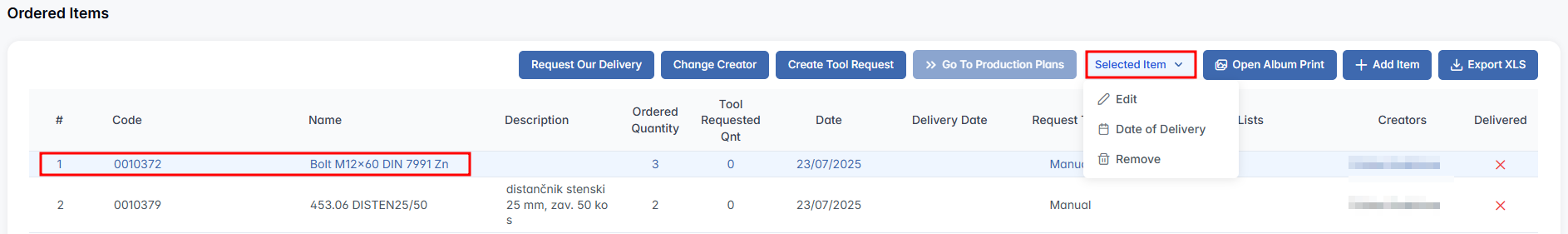

- Selected Item menu lets you:

- Additional buttons:

- + Add Item: Manually adds a new item to the chain

- Export XLS: Download a list of ordered items

- Open Album Print: Print related visuals or data.

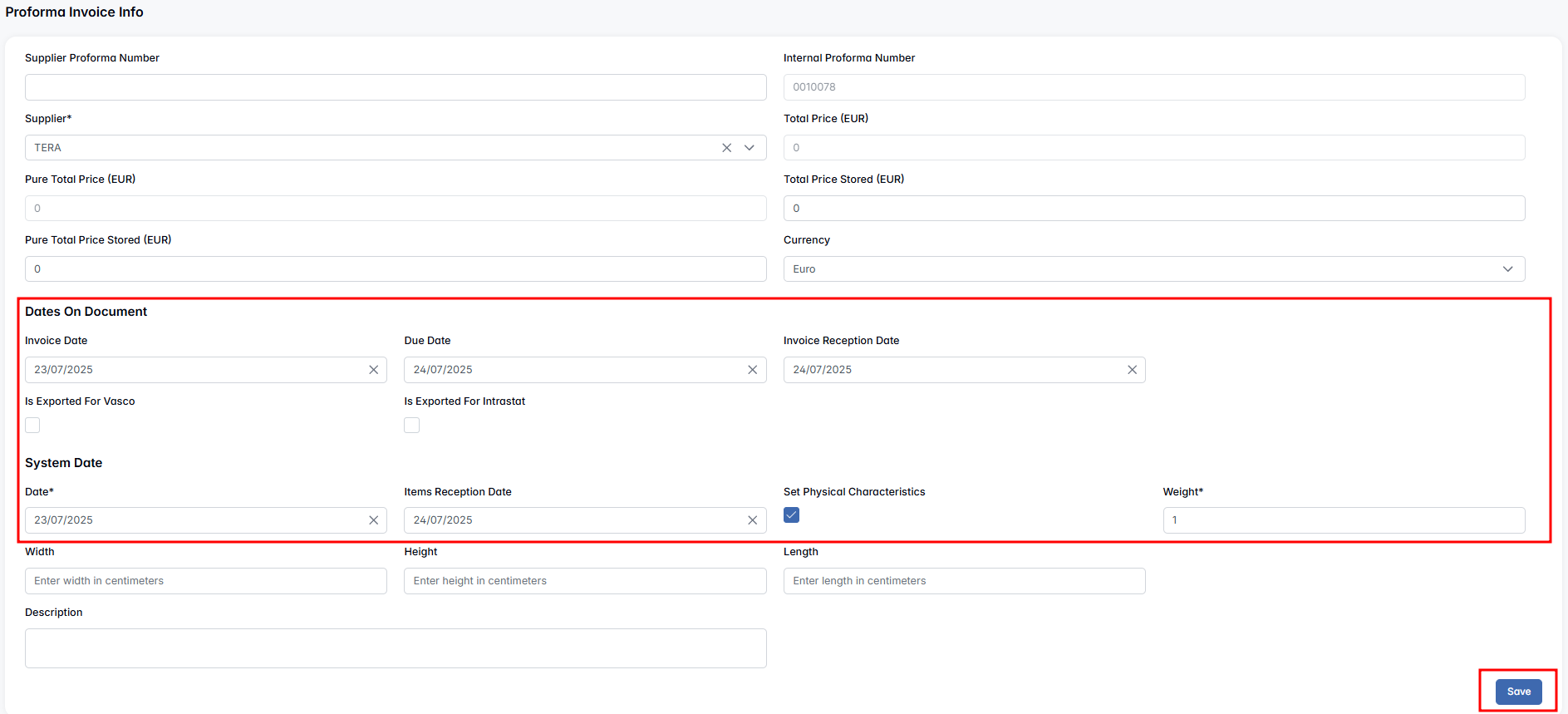

Proforma Invoices Section

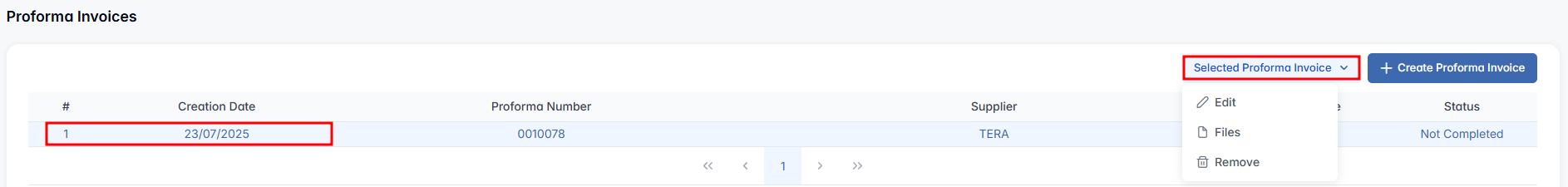

Click + Create Proforma Invoice to register a new proforma invoice. A confirmation modal will pop up — click Confirm to proceed. This action creates a default row in the Proforma Invoices table, which includes all ordered items that are not yet part of any proforma and not yet invoiced.

All relevant details — such as proforma invoice dates, quantities, prices and file attachments — must be reviewed and completed in the next step by editing the Proforma Invoice. This ensures that the invoice is correctly prepared for the next stages of delivery and quality control.

Once a row is created, the Selected Proforma Invoice button becomes active. When you click it after selecting a row, you’ll get three options:

- Edit — opens the Proforma Invoice Edit page. Here, you can:

- Set Dates on Document, including System Date (mandatory before proceeding to QC)

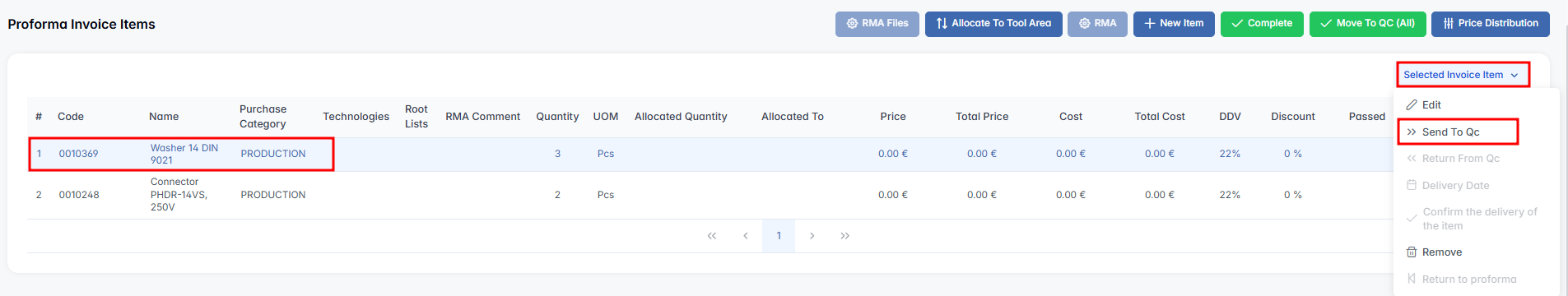

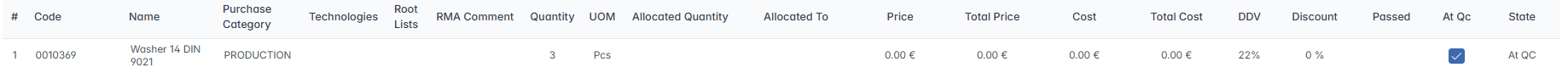

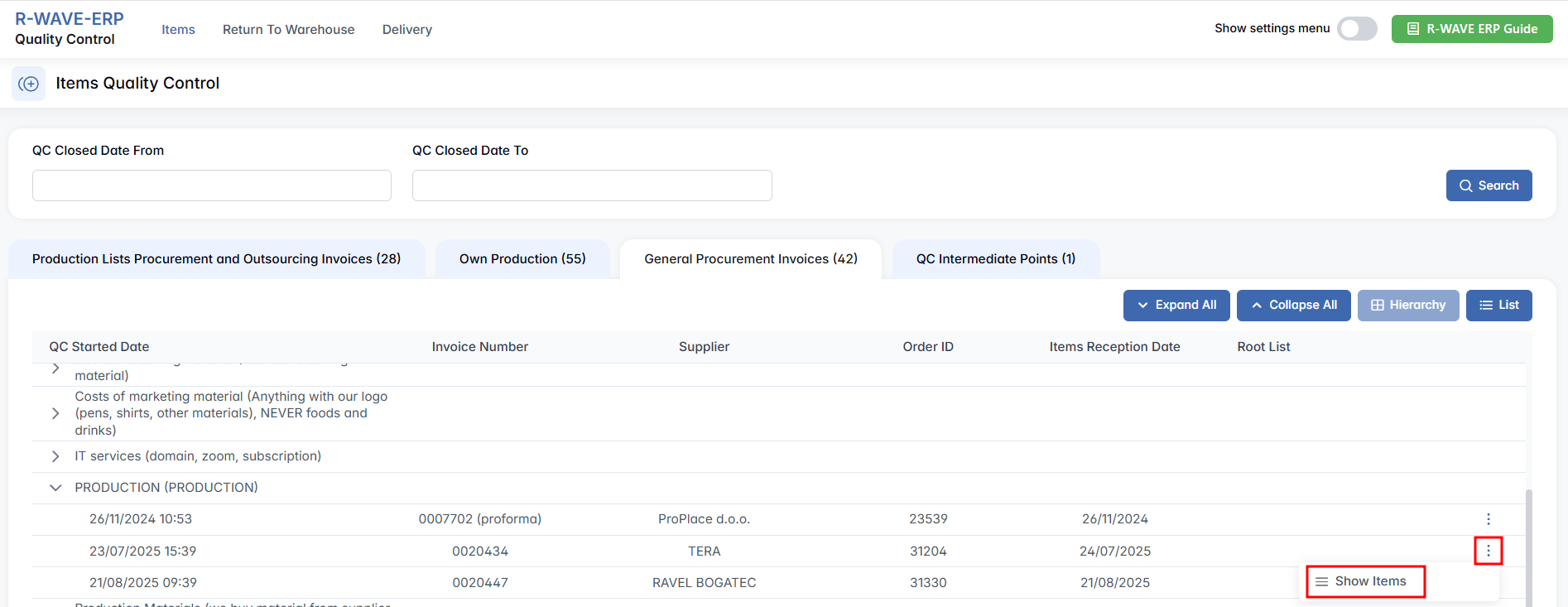

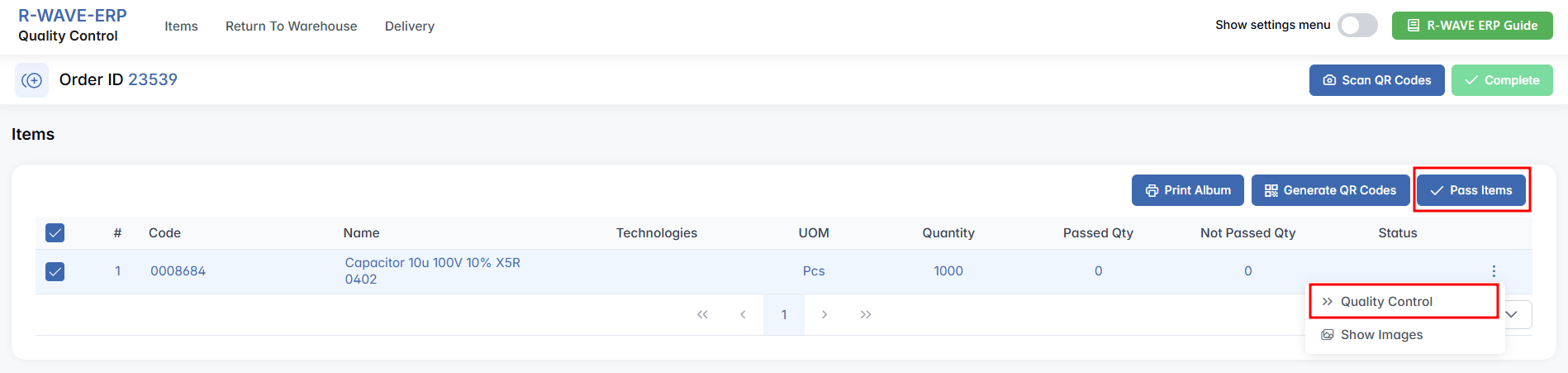

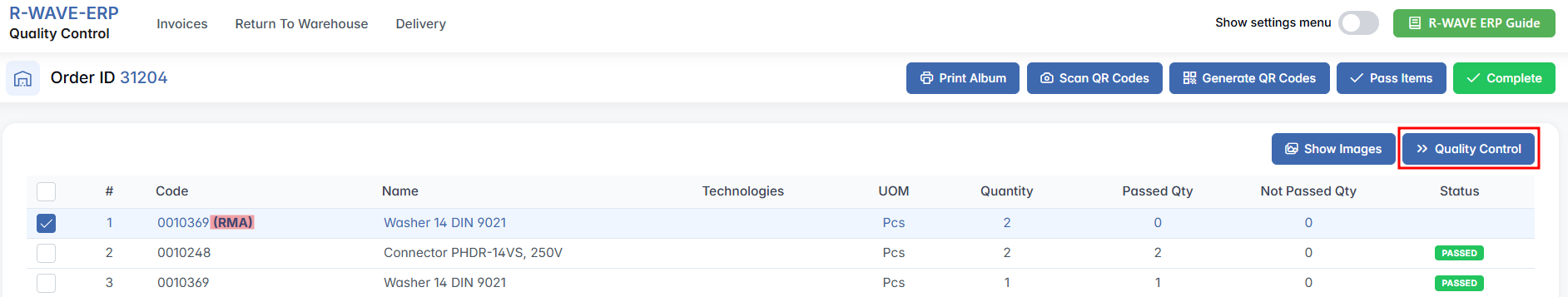

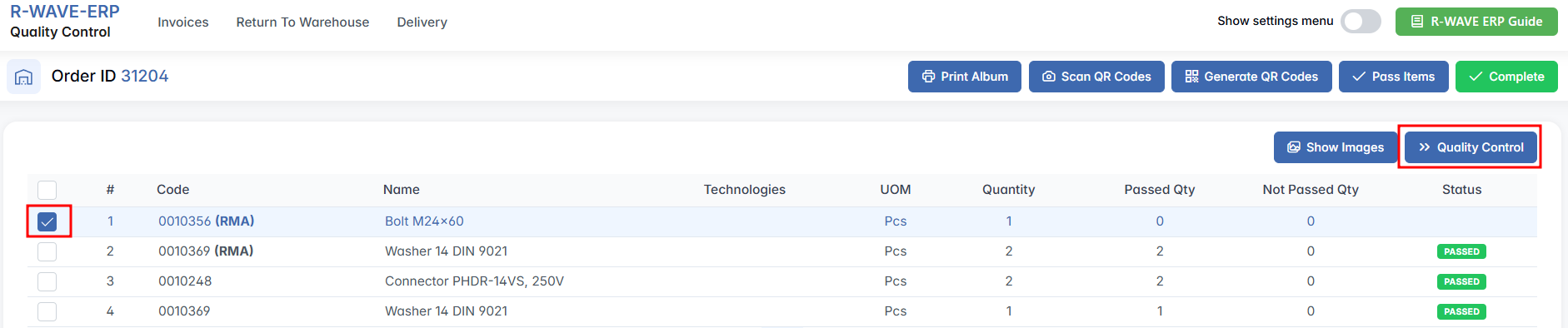

To approve or reject items in Quality Control, the user must go to the QC module, open the Items section, and navigate to the Production List/General Procurement Invoices subsection. From the list, click the three-dot menu next to the invoice item you would like to choose and select “Show Items” to view the associated invoice items.

On the invoice page, any item awaiting QC will be listed. To proceed, select the checkbox next to the item row and either:

- Click the “Pass Items” button to quickly mark the selected quantity as passed, or

- Click the three dots menu next to an item and select “Quality Control” to open a detailed evaluation window.

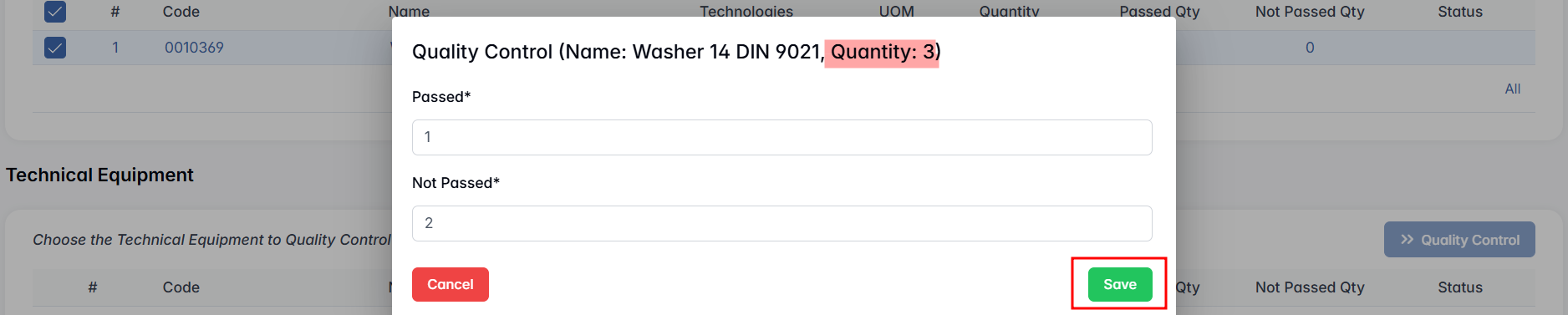

In this popup window, the user must enter the number of units that Passed and Not Passed. The system will show the total quantity expected, and the “Save” button becomes active only when the sum of passed and not passed units exactly matches the expected quantity.

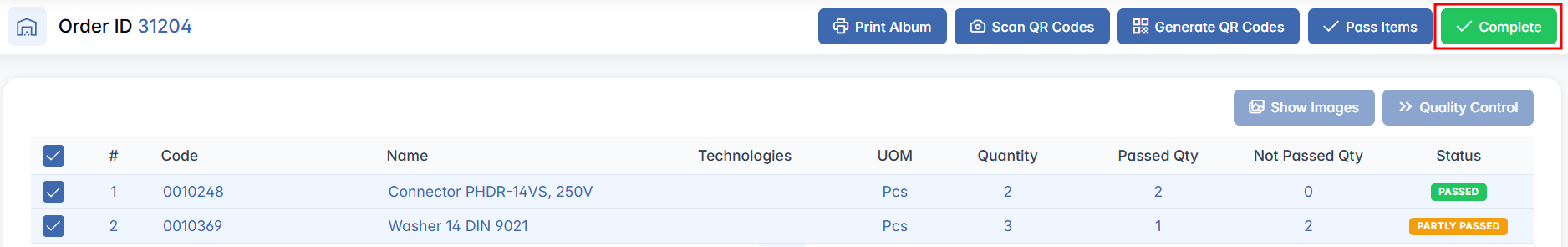

Based on the results:

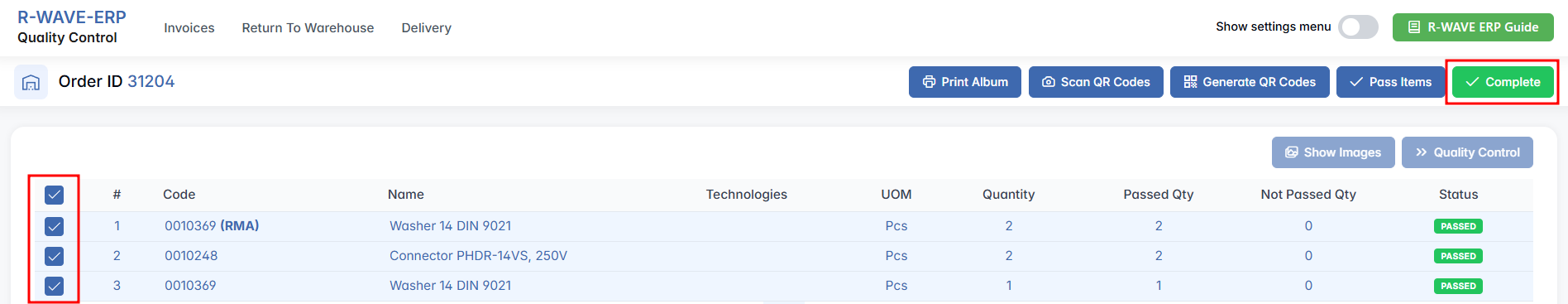

Once QC evaluation is complete, click the “Complete” button to finalize the Proforma Invoice.

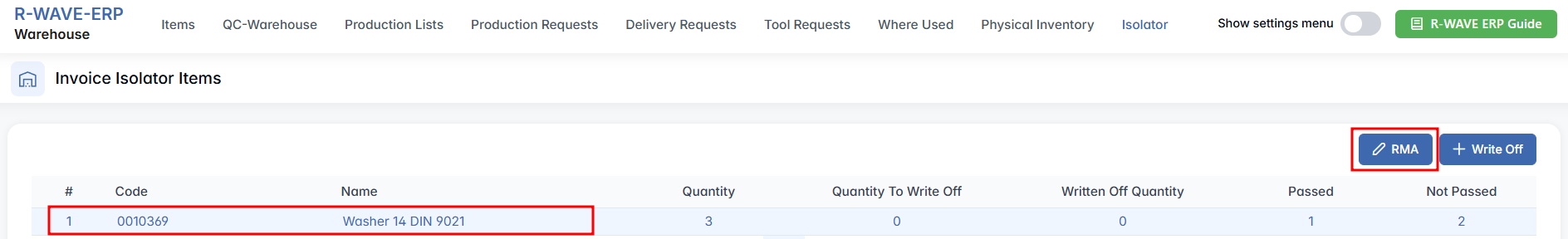

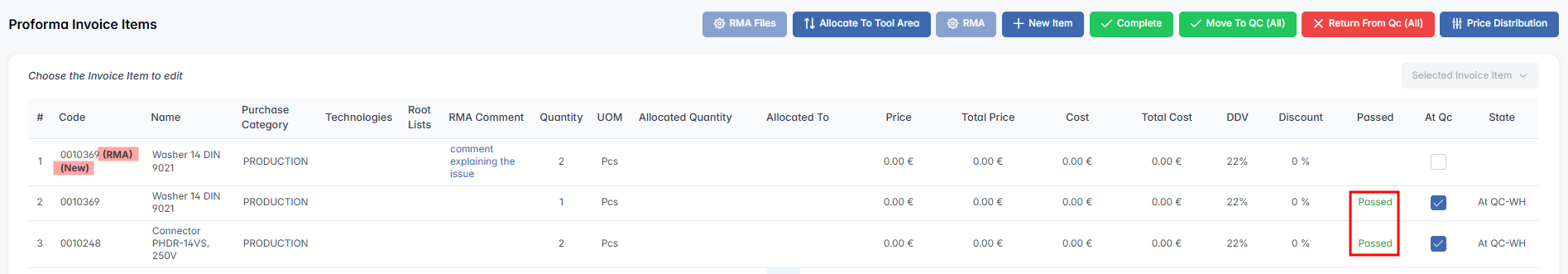

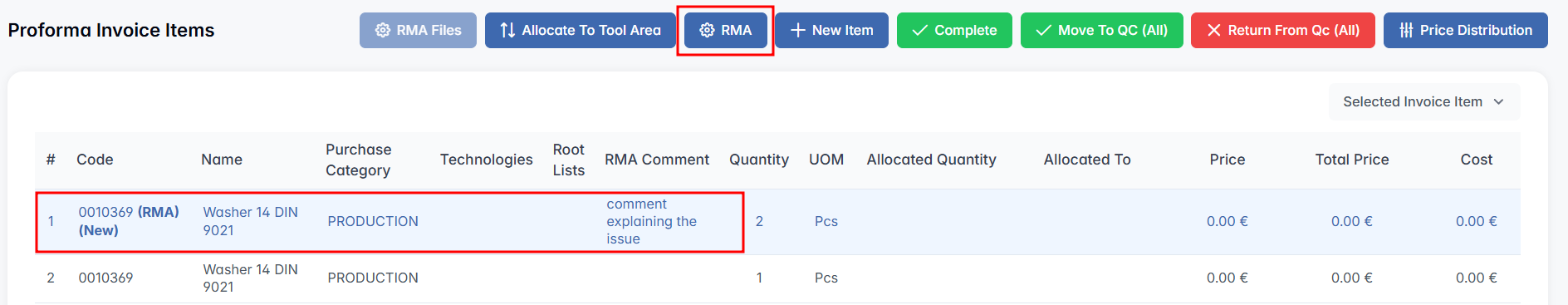

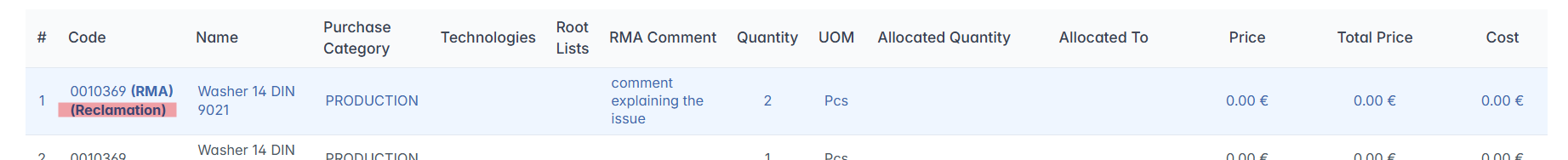

Once the QC evaluation is completed, refresh the Proforma Invoice/Invoice Items tab which will now display the updated statuses for each item. Items that have successfully passed QC are shown with a green "Passed" label, while those that failed are marked with an (RMA)(New) label, indicating they were sent to Return Merchandise Authorization handling.

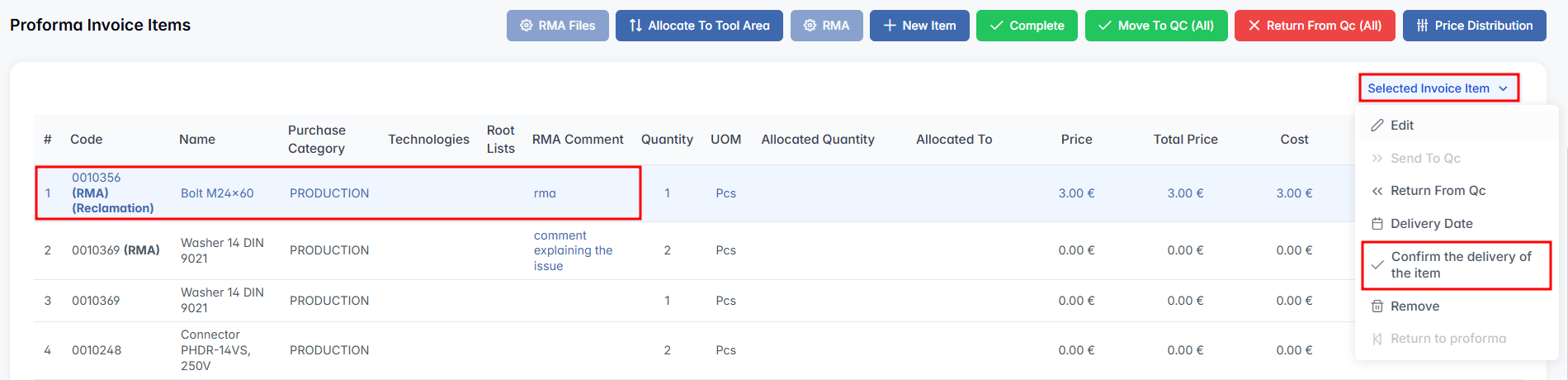

When you go back to the Order page and choose an invoice, you can also click on Selected Invoice Item option to add or view Files (supporting documents) or Remove the invoice (if the invoice contains items that have been sent to QC but not yet returned, this option is unavailable).

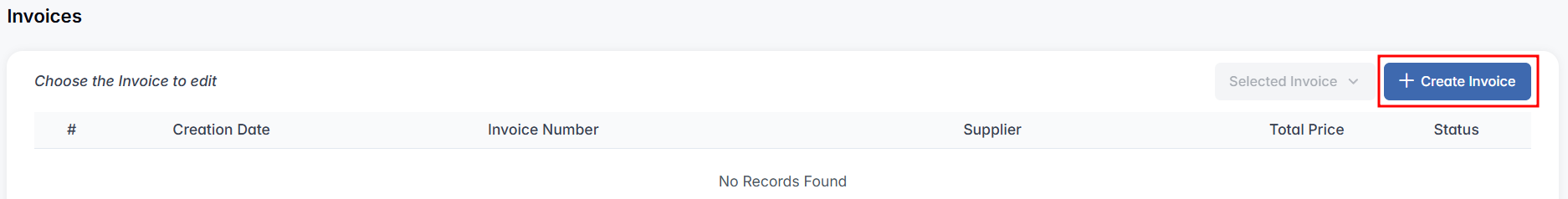

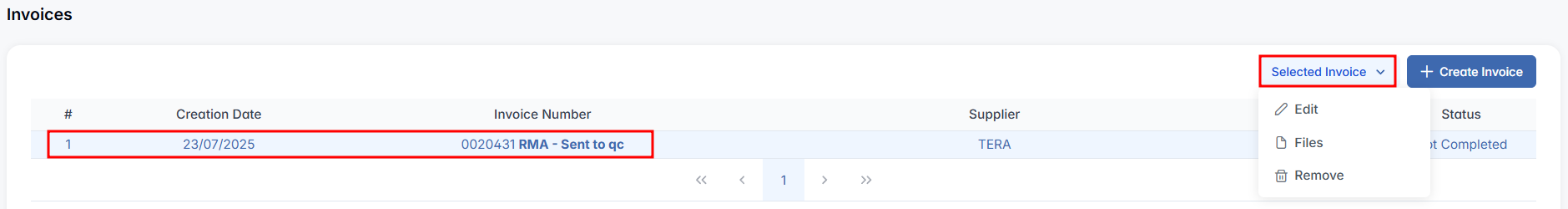

Invoices Section

To register a final original invoice, click +Create Invoice.

A confirmation modal appears — click Confirm to proceed. The system will generate a new invoice row in the table, containing:

- All ordered items that were:

- Already included in a Proforma Invoice, and

- Not yet invoiced elsewhere.

Invoices and Proforma Invoices share nearly identical structure and functionality in R-Wave ERP. However, the invoice serves as the final financial document used for billing and payment processing, whereas the Proforma Invoice is more of a preliminary record for delivery and QC purposes.

After an invoice is created, the Selected Invoice button becomes active when a row is selected. Options include:

- Edit — Opens the invoice in the Reports Module, where you can:

- Complete invoice fields (dates, attached files, services).

- View auto-calculated totals (Total Price, Pure Total), which cannot be manually edited.

- Files — Attach or view supporting documents.

- Remove — Deletes the invoice, if allowed by system conditions.

Invoice Edit Page: Overview

The Invoice Edit page allows users to adjust invoice metadata and manage invoice items, following the same logic and structure as in the Proforma Invoice interface.

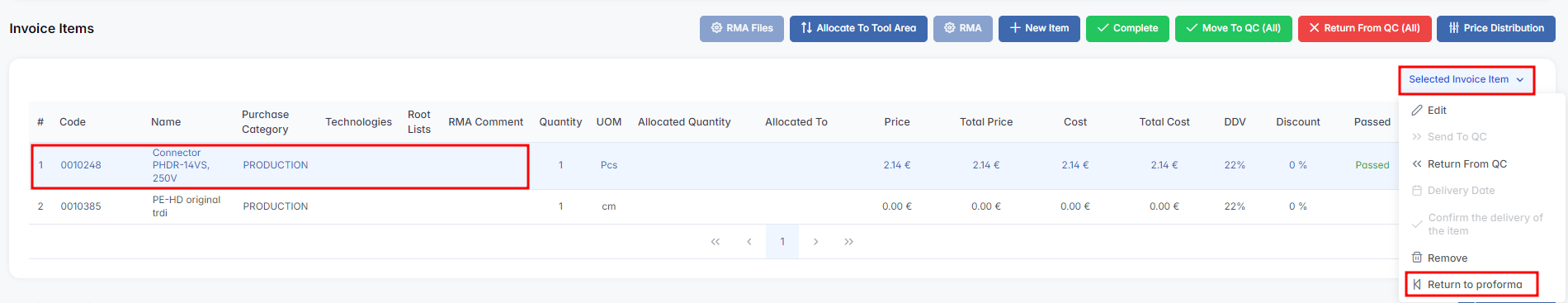

When a row is selected from the Invoice Items section of the invoice, the Selected Invoice Item menu becomes active. One of the key options available here is:

This option allows the user to remove selected items from the current invoice and move them back to the Proforma Invoice section.

It is used in scenarios where not all items should be included in the final invoice — for example, if only part of the ordered items have been invoiced by the supplier at this stage. Since the system automatically includes all items from the related Proforma Invoice during invoice generation, the user may need to manually adjust the invoice contents to reflect the real-life invoice received from the supplier.

Using Return to Proforma ensures that items not covered by the current invoice remain properly tracked and can be invoiced later. It prevents double billing and preserves accuracy between system records and external supplier documents.

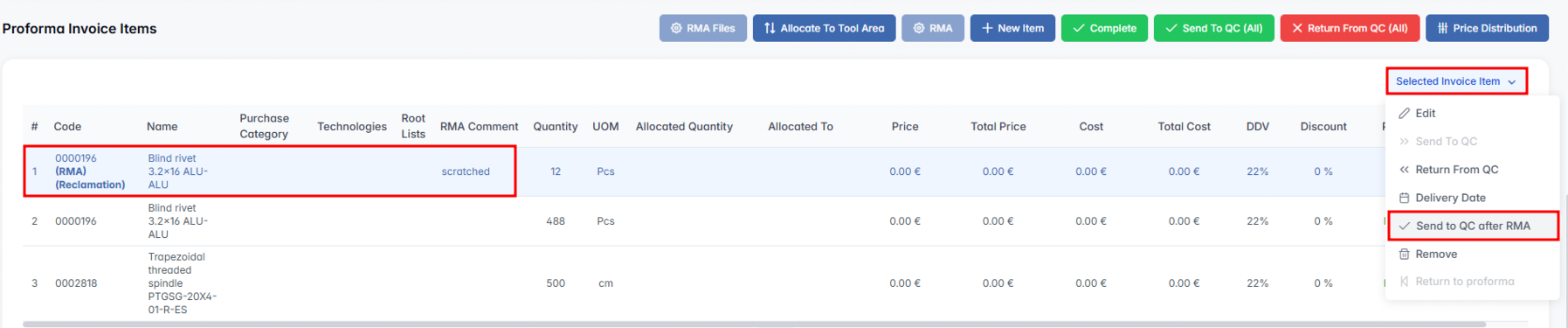

RMA (Return Material Authorization)

The logic described in this section applies to both Proforma Invoices and Invoices. Regardless of the document type, RMA actions follow the same process and interface behavior.

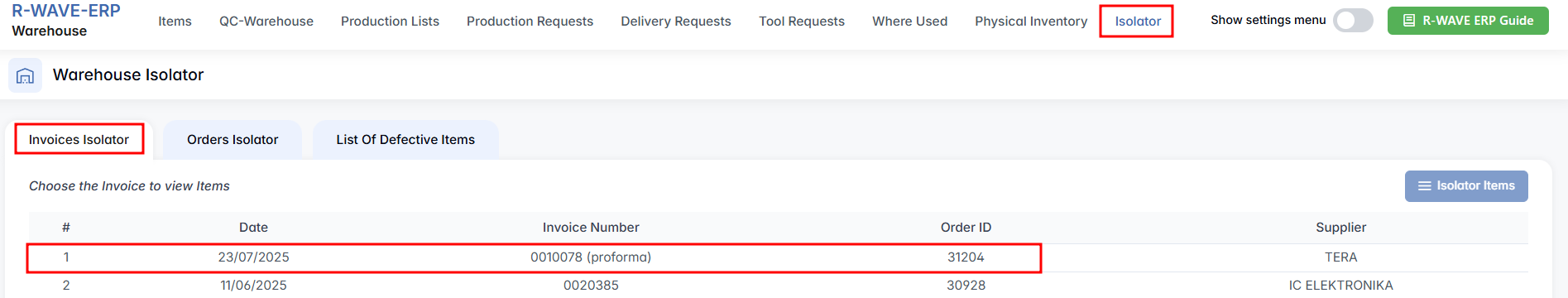

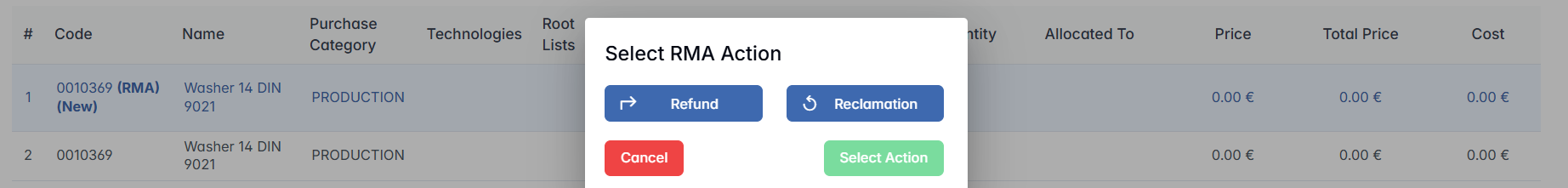

If any items are rejected in QC and sent to Isolator, they can be marked with an (RMA) label. When such an item is selected, the RMA button becomes active.

Clicking RMA opens a window with two options:

- Refund: Issues a monetary refund. (Note: this only works if a final invoice was already created. Otherwise, the system will display an error)

- Reclamation: Triggers a replacement item from the supplier.

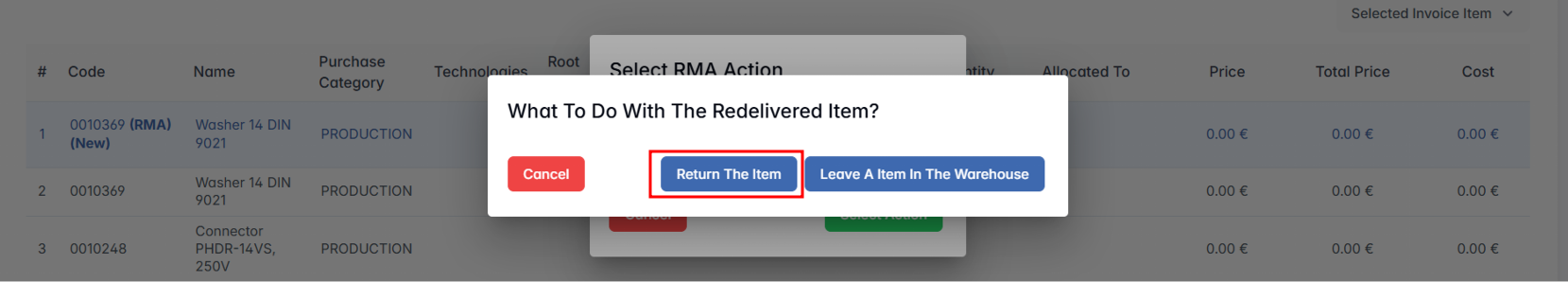

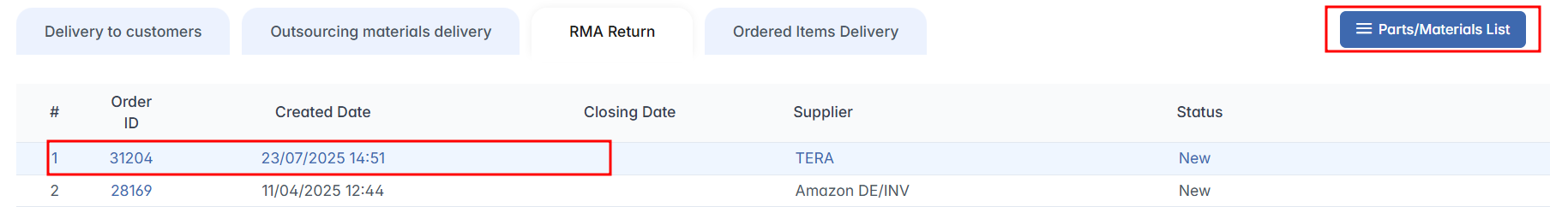

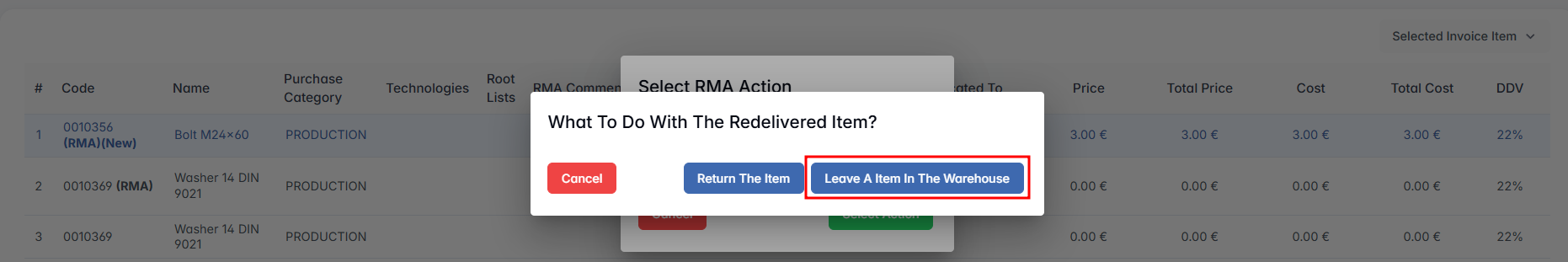

After choosing Reclamation, you'll be prompted: "What to do with the redelivered item?"

- Return the item

Requires the user to follow these steps:

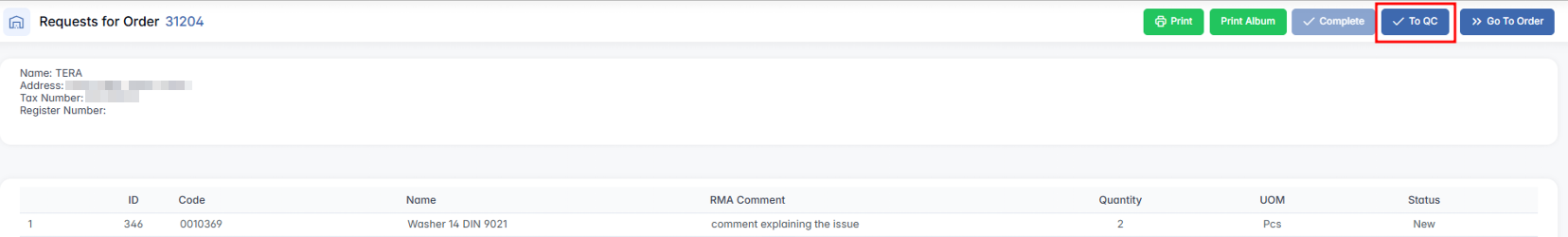

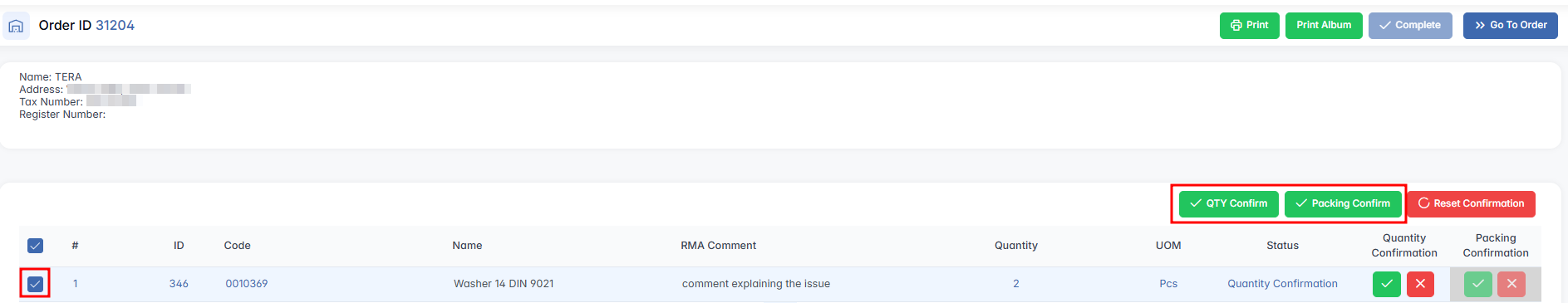

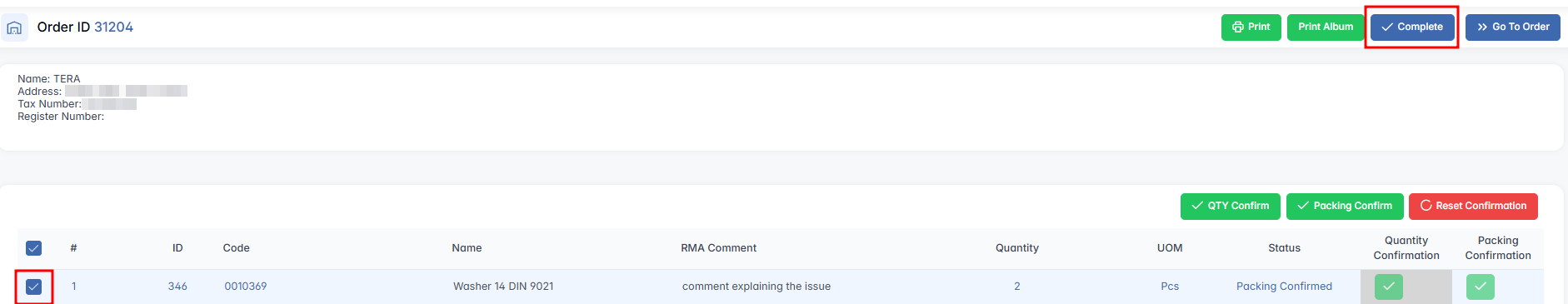

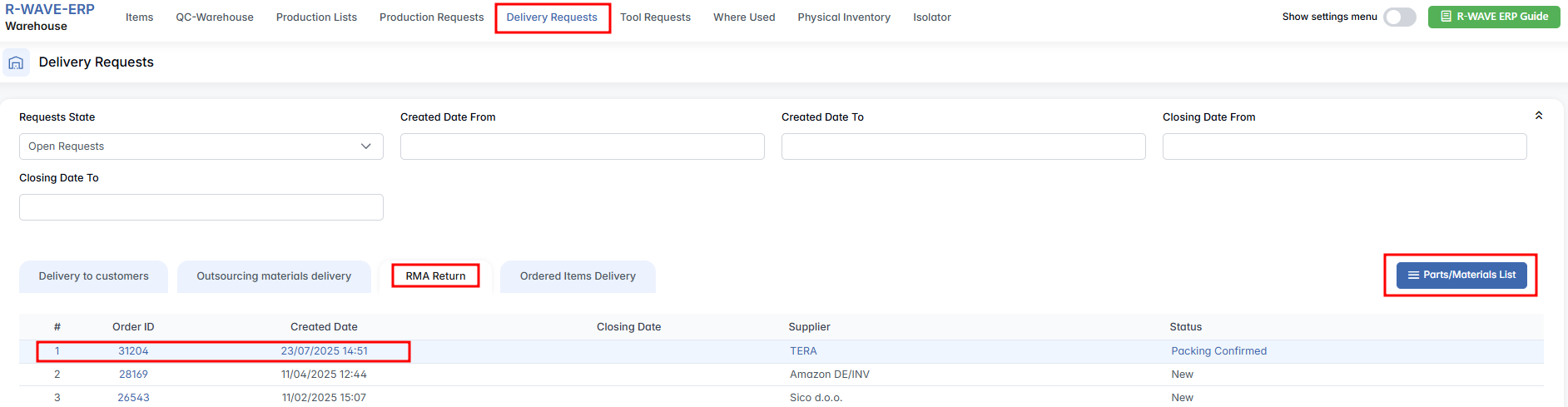

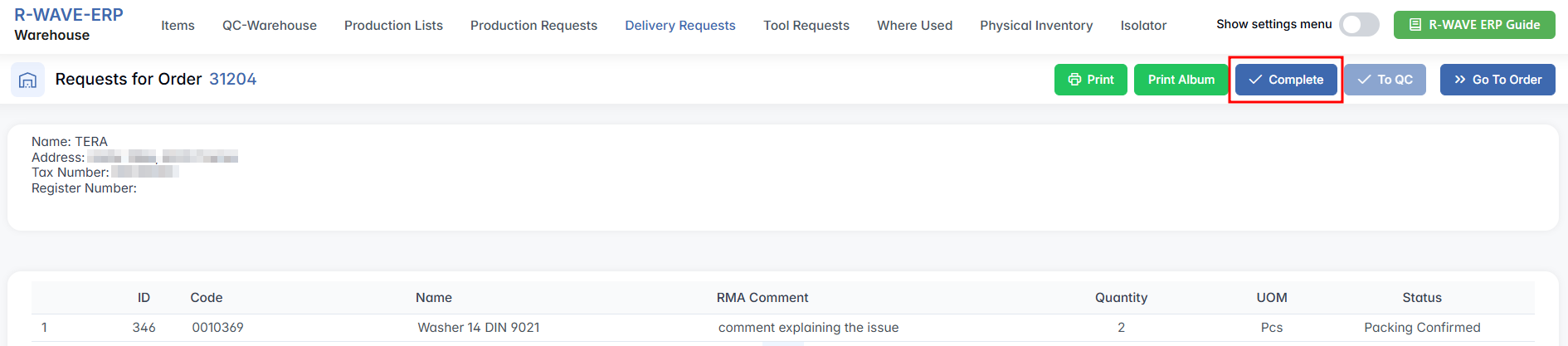

1. Go to Warehouse > Delivery Requests > RMA Return

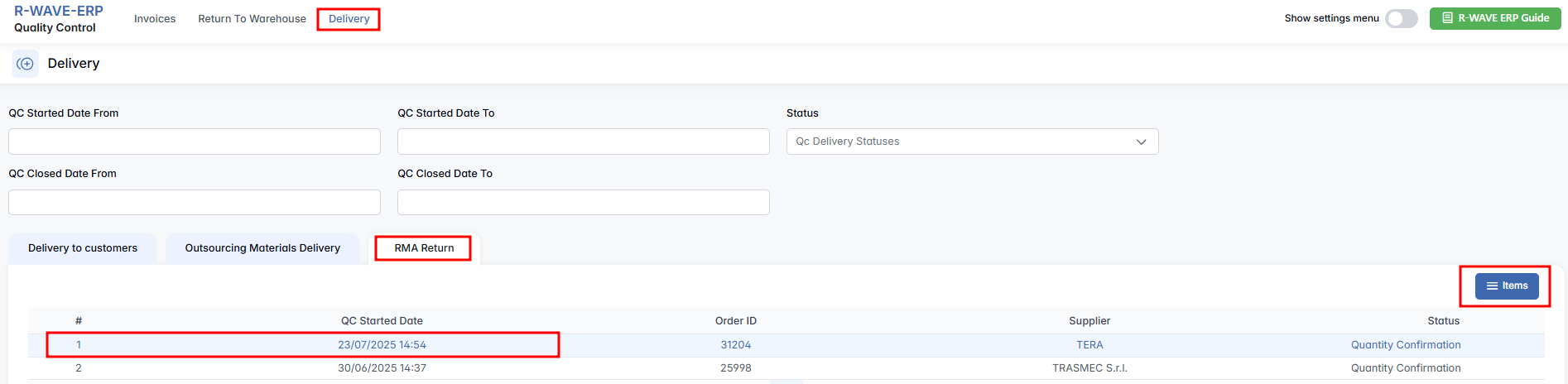

2. Move item to QC

3. Go to Quality Control > Delivery > RMA Return

4. Confirm Quantity and Packing

5. Click Complete

6. Go to Warehouse > Delivery Requests > RMA Return

7. Click Complete

8. Return to the Proforma Invoice/Invoice Edit page and click Send to QC after RMA

9. Perform a new QC round for the re-delivered item marked with (RMA)

10. Click Complete

- Leave An Item in the warehouse:

No warehouse movement is needed at this stage. Once the redelivered item has physically arrived and the delivery has been performed, go to the Proforma Invoice/Invoice Edit page and use the Confirm Delivery of the Item function to register its arrival in the system. This step ensures that the item is officially marked as received and can proceed to quality control if needed.

QC will still be performed on the new (RMA) item. Preform the quality control then Click Complete.

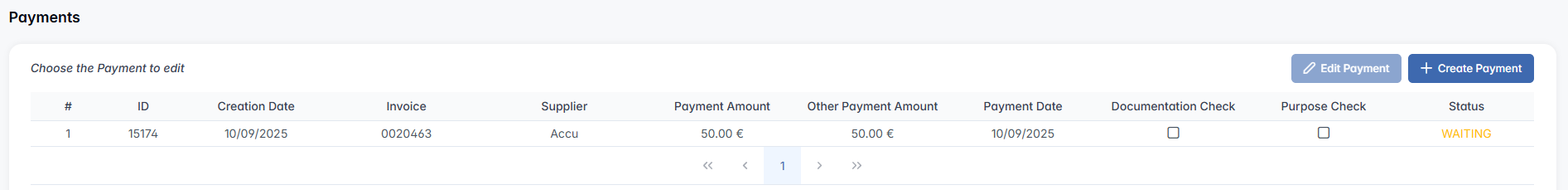

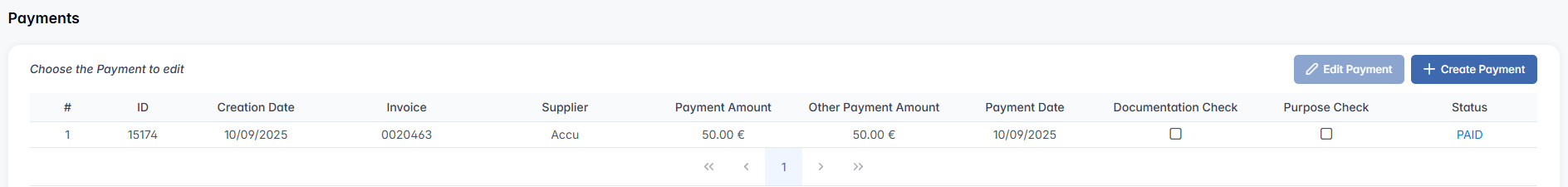

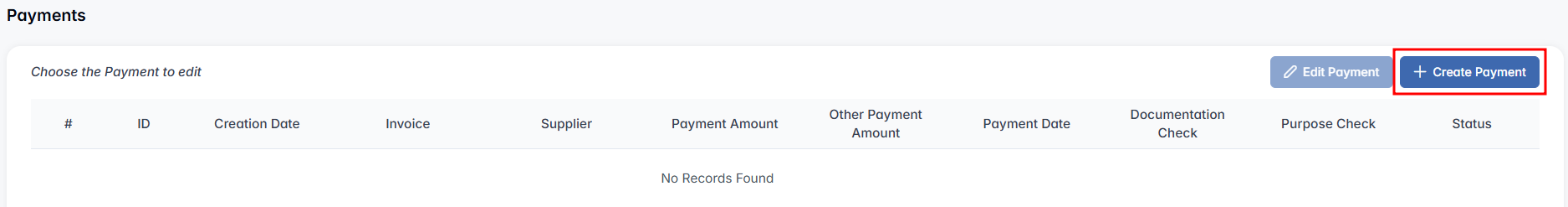

Payments

Once the invoice has been created and confirmed, the next essential step is to register the payment for this invoice. Recording payments ensures that financial operations stay transparent and trackable within the ERP system, allowing the company to monitor which orders have been settled and which are still pending.

To proceed with the payment:

- Navigate to the Order Page of the corresponding Procurement Chain.

After the Proforma Invoices and Invoices sections, locate the Payments section. - Click the + Create Payment button to begin the payment registration process.

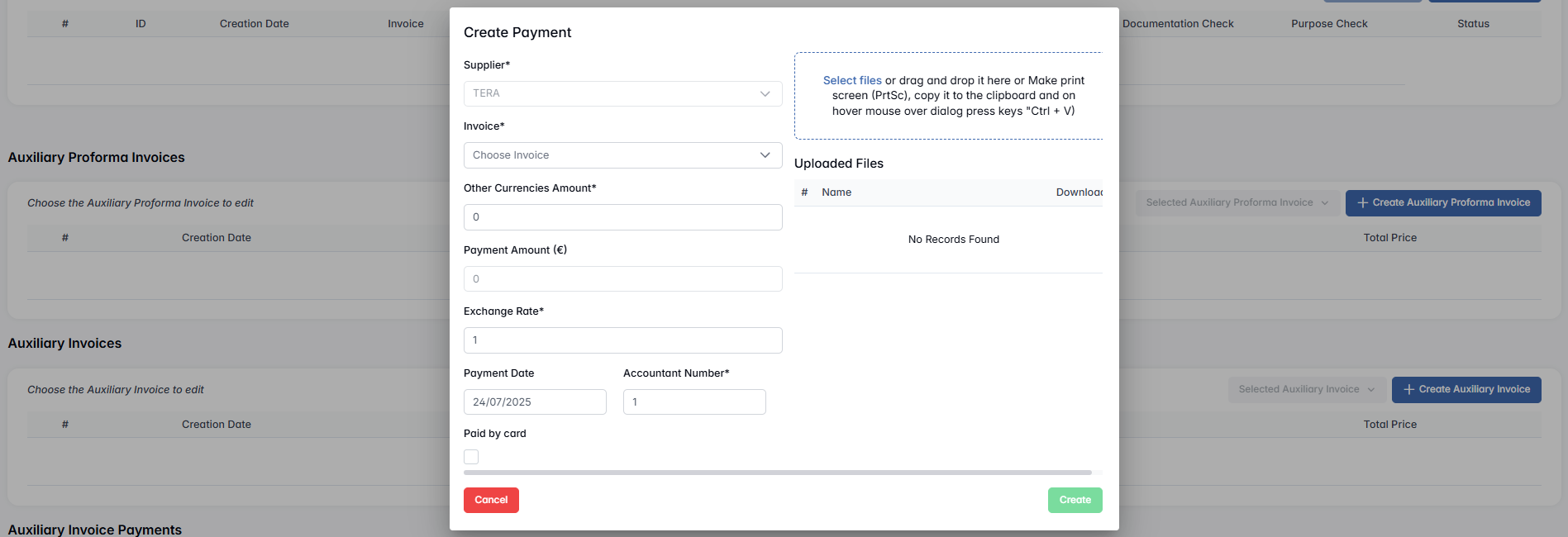

- A pop-up window titled Create Payment will appear. Fill in the form with the required details:

- Supplier – This field is auto-filled based on the chain’s data and indicates who the payment is being made to.

- Invoice – Select the corresponding invoice(s) from the dropdown list. These invoices must have been created and listed in the invoice section above. You may select multiple if applicable.

- Actual Amount – This field may auto-fill based on the invoice but can also be manually edited. Use it to enter the actual amount being paid to the supplier, in their currency. It also supports partial payments.

- Payment Amount (€) – This field reflects the amount converted into Euros. It is not editable and duplicates the value from the previous field, converted using the exchange rate.

- Exchange Rate – Enter the conversion rate used for this transaction.

- Payment Date – Define the date when the payment was or will be made.

- Accountant Number – Enter the bank account number of your company.

- Paid by Card – Tick this box if the payment was done by credit/debit card instead of a bank transfer.

- Uploaded Files – You can attach documents that prove the payment, such as bank confirmations or screenshots. Files can be uploaded via drag-and-drop, the file picker, or pasted directly from your clipboard.

- Click the Create button to save the payment.

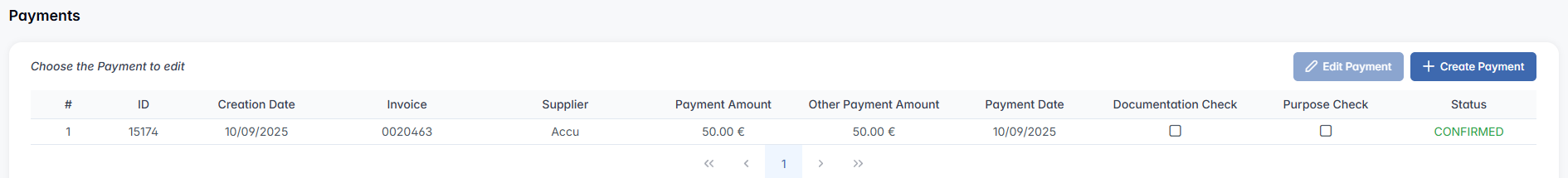

A new payment record will appear both in the Payments section of the procurement chain and in the Payments module. Initially, the status will be set to WAITING, as the payment must be confirmed through the Confirmation module under the Payments Confirmation tab.

Once confirmed, the status will change to CONFIRMED.

And when the payment is actually completed, it will be updated to PAID.

Users can create multiple payment records if partial payments are required. However, the total sum of all payments for the same invoice must not exceed the invoice amount.

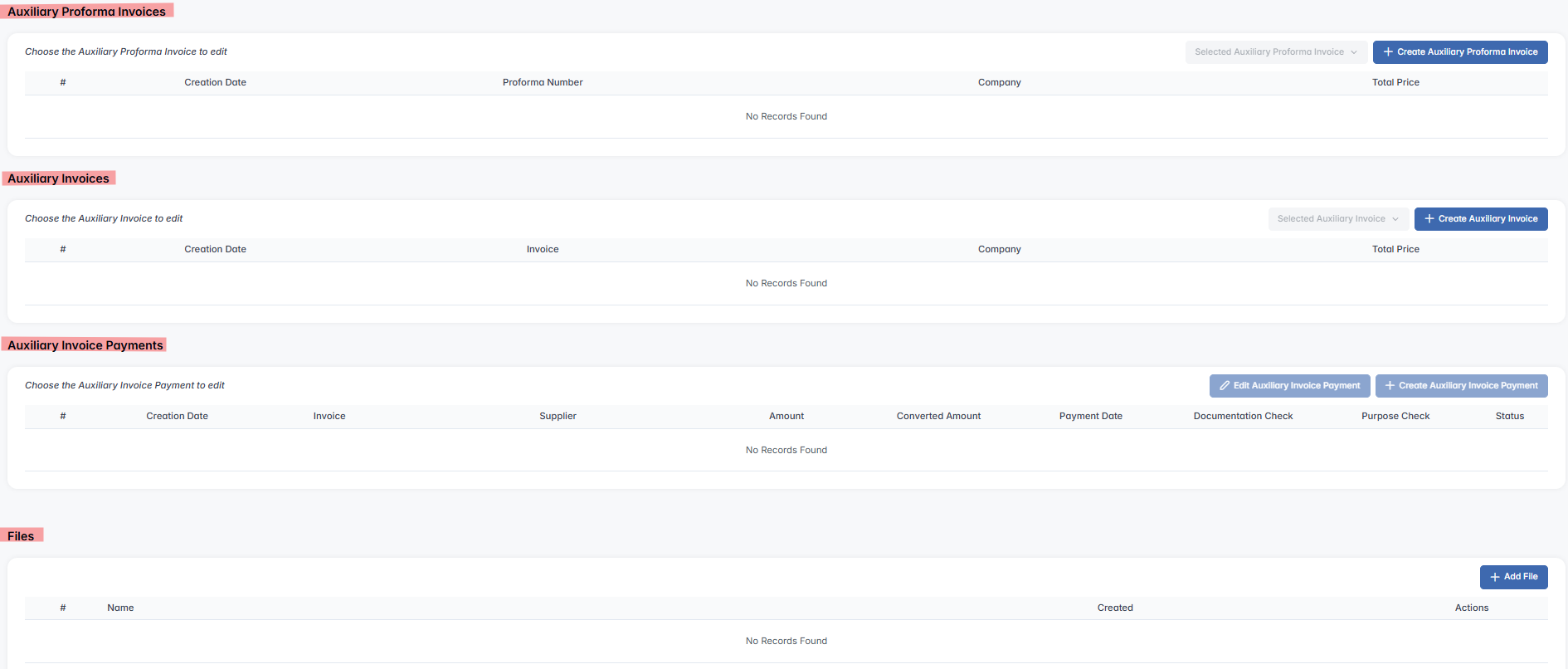

Additional Financial Records

If the delivery requires extra services (such as customs, logistics, or special fees), you can also document them using the following options:

- Auxiliary Proforma Invoices – For services that need to be quoted and verified before billing.

- Auxiliary Invoices – Final service-related invoices received from external providers.

- Auxiliary Invoice Payments – To register payments for the above invoices.

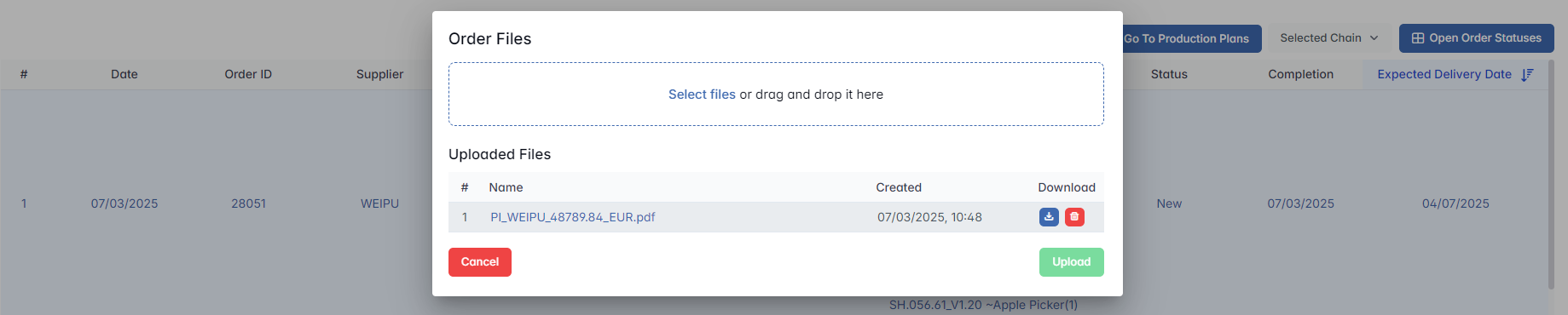

- Files – Any related supporting documentation (contracts, delivery notes, receipts) can be uploaded to the chain using the Add File function.

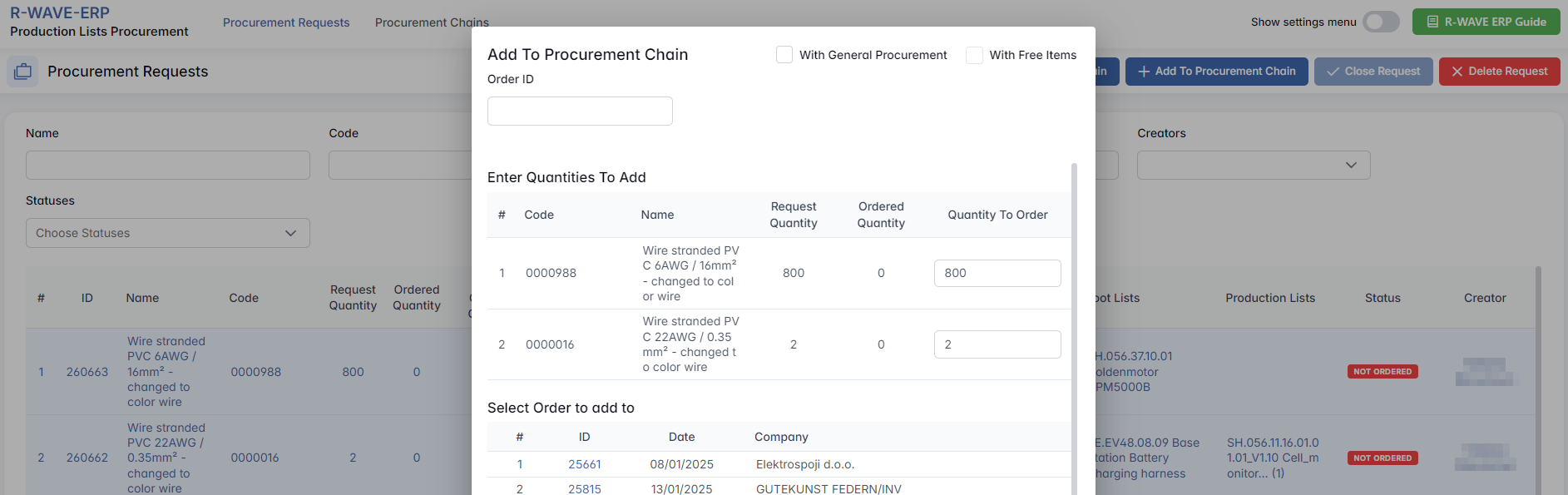

Adding to Procurement Chain

The + Add To Procurement Chain function is used when a selected procurement request can be fulfilled using an existing procurement chain that already contains sufficient Free Ordered Quantity or because the requested item can still be added to that chain. Instead of creating a new procurement order, this action allows users to link the request to an existing chain, helping to avoid duplication, optimize procurement efforts, and maintain clear order tracking.

When you click the + Add To Procurement Chain button, a pop-up window appears listing all procurement chains with available quantities that match the current request. Select the appropriate chain(s) and confirm the action to include the request. This process ensures efficient use of already ordered stock and maintains clear tracking of which requests are being fulfilled through shared procurement.

Fill in the form with the required details:

- Order ID – Direct search by order identifier.

- Enter Quantities To Add – Enter how many items you would like to order.

- With Free Items – If checked, only procurement chains that contain the requested item with available free quantity will be shown.

- With General Procurement – If checked, the production procurement request will not create a separate production-only order but will instead be linked into the general procurement chain, combining production needs with overall company procurement. This helps avoid splitting orders across multiple chains and allows centralized handling of quantities.

With Free Items (checked)

- The request is covered by the chain’s already ordered but unallocated stock.

- Ordered quantity does not increase.

- Free quantity in the chain decreases by the amount allocated to the request.

- This option is only available if the requested item already exists in the chain.

Without Free Items (unchecked)

- The requested quantity will be added to the ordered quantity of the chain.

- If the item already exists in the chain – ordered quantity for that item increases.

- If the item does not exist in the chain – a new item record is created, and ordered quantity is set equal to the requested quantity.

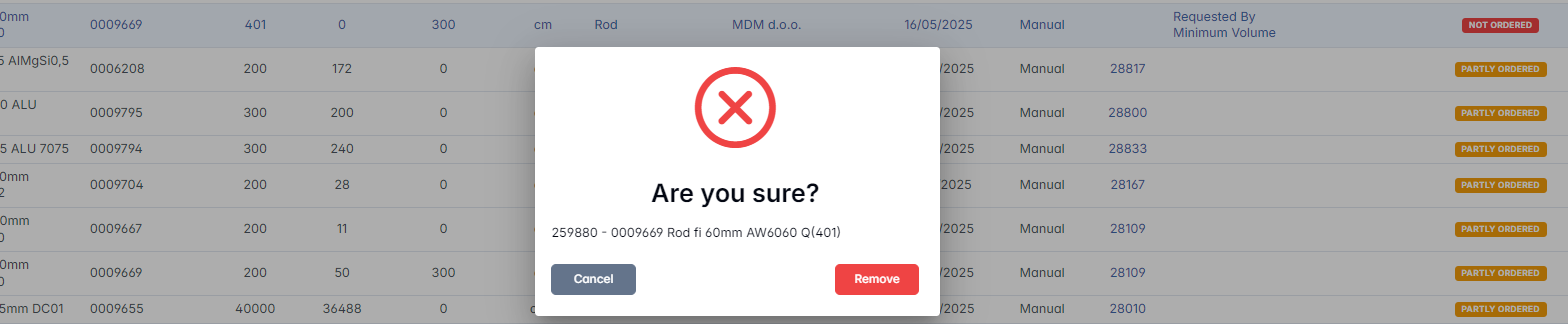

Deleting Request

If the user selects a Not Ordered item and clicks Delete request, a confirmation modal appears:

Only Not Ordered records can be deleted.

Procurement Chains

Procurement Chains

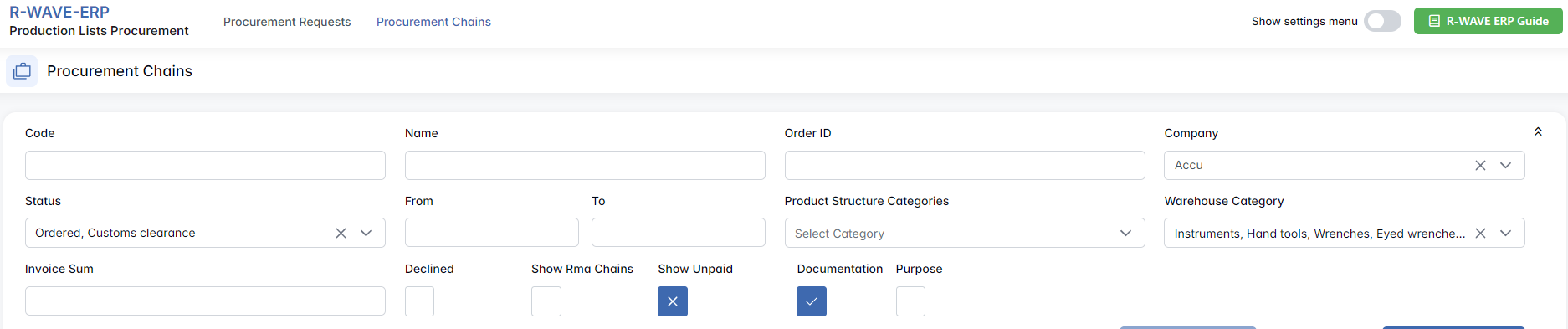

The Procurement Chains page is designed to help users monitor, search, and manage procurement requests grouped into chains. It provides detailed filtering options to locate specific procurement chains and allows users to view, update, and maintain the status and documentation related to these chains. This page supports procurement process tracking and coordination between suppliers, warehouses, and internal teams.

Filter Section

The page includes a comprehensive filter panel to narrow down procurement chains by multiple criteria:

| Filter Field | Description |

|---|---|

| Code | Filter by item/product code |

| Name | Filter by item/product name |

| Order ID | Filter by specific procurement order number |

| Company | Select one company from a dropdown to filter orders by supplier or client company |

| Status | Multi-select status filter for order statuses (e.g., New, Sent to QC, Unpaid, etc.) |

| From / To | Date range filter to select procurement chains created within specific dates |

| Product Structure Categories | Multi-select hierarchical filter based on product categories |

| Warehouse Category | Multi-select hierarchical filter related to warehouse categories |

| Invoice Sum | Filter by total invoice amount |

Additionally, several checkboxes allow further filtering:

- Declined

- Show RMA Chains (Return Merchandise Authorization related chains)

- Show Unpaid

- Documentation — indicator for whether all required files are attached

- Purpose — whether the payment’s justification is complete

Checkboxes have a three-state toggle. The first click marks the checkbox with a check (✔), meaning to include items with this attribute. The second click changes it to a cross (✖), meaning to exclude items with this attribute. The third click clears the checkbox, meaning no filtering by this attribute.

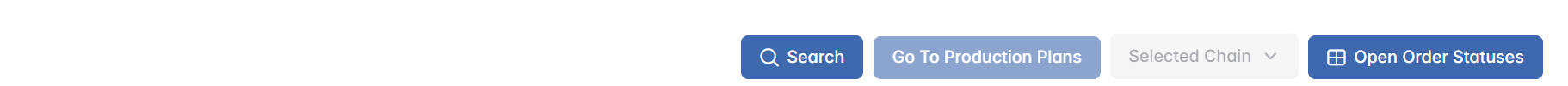

Action Buttons

Search — Applies the current filter selections and updates the procurement chains table.

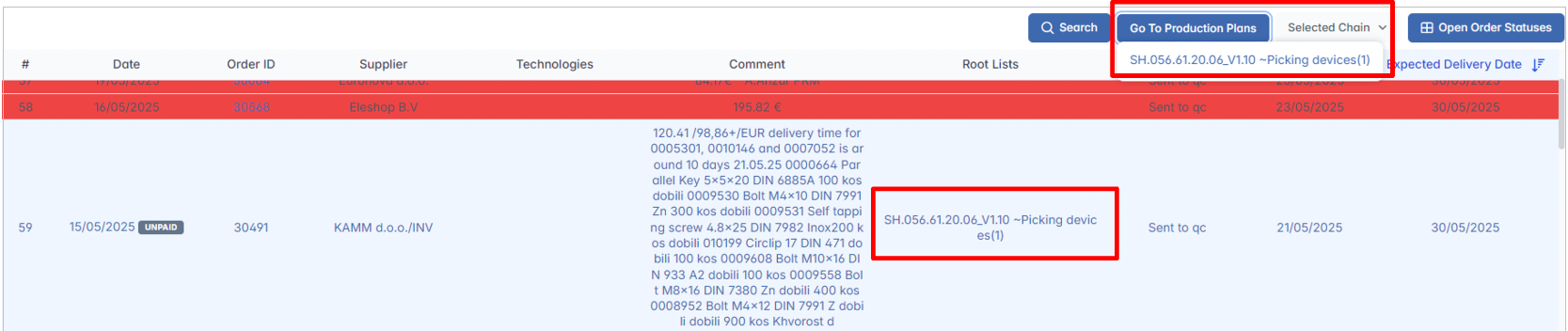

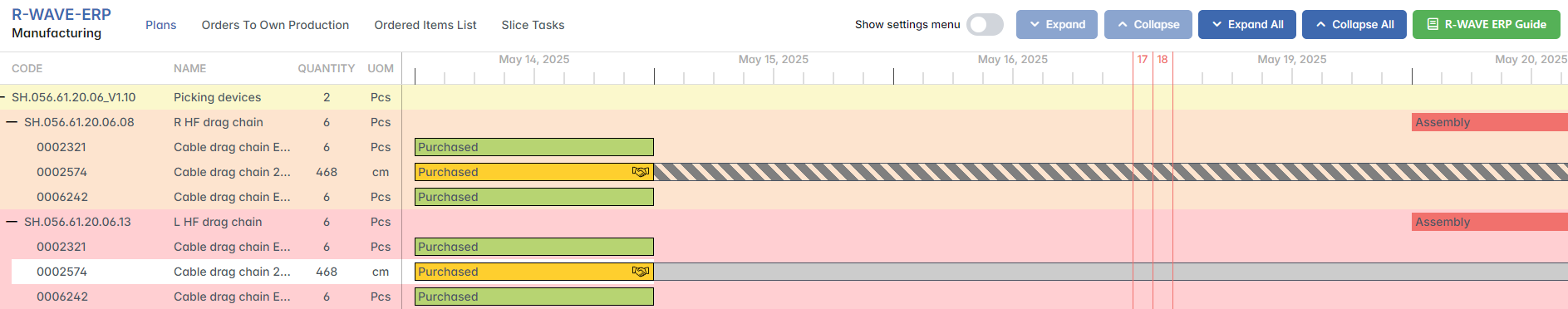

Go To Production Plans — This button redirects the user to the Production Plan from which the selected position was originally formed. It is only active if the selected row(s) contain a value in the Root Lists column; if the column is empty, the button remains inactive.

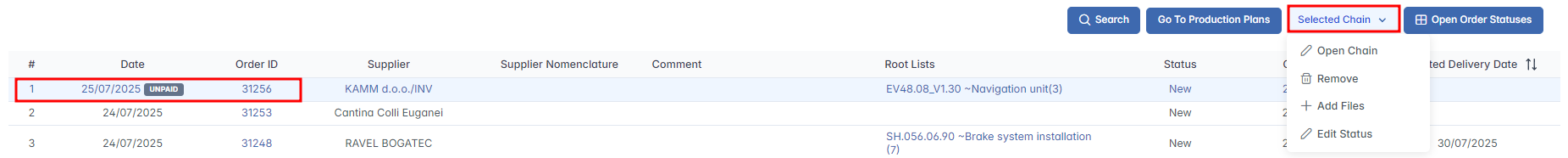

Selected Chain — This button activates only after the user selects a row in the table. When clicked, it shows options for managing the selected procurement chain: Open Chain, Remove, Add Files, Edit Statuses

Open Order Statuses — Clicking this button changes the table view to show detailed order statuses. The button then changes to Close Order Statuses, which lets the user return to the previous table view.

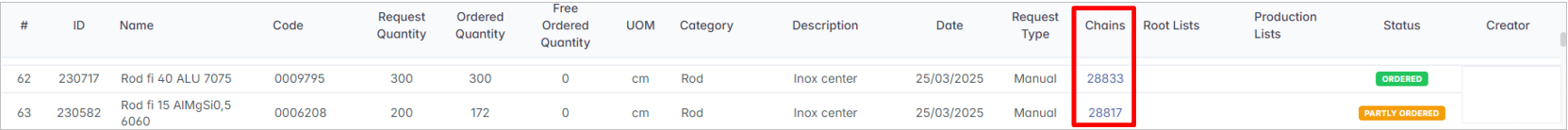

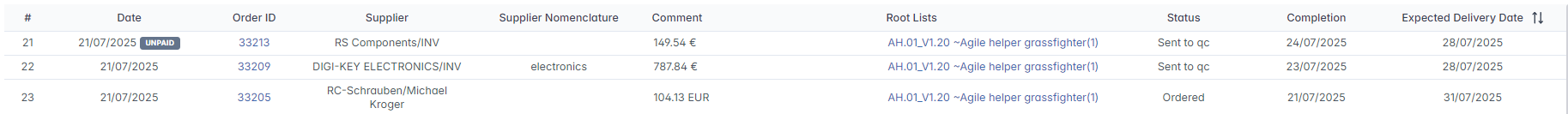

Procurement Chains Table

The main table lists procurement chains with the following columns:

| Column | Description |

|---|---|

| Date | Creation date of the procurement chain |

| Order ID | Unique identifier for the procurement order |

| Supplier | Supplier or company name |

| Supplier Nomenclature | Item name, code, or identifier as provided by the supplier |

| Comment | Notes or comments associated with the order |

| Root Lists | Indicates the root list of requests; if empty, related actions (Go To Production Plan) are disabled |

| Status | Current status of the procurement chain |

| Completion Expected Delivery Date | Expected date of completion or delivery (sortable ascending/descending) |

Selected Chain Options

When a procurement chain row is selected, the Selected Chain button activates and offers management options:

Open Chain

Opens a dedicated page Order #### that displays comprehensive details: Order information, Ordered items, Proforma invoices, Invoices, Payments and other related procurement data.

Remove

Allows deletion/removal of the selected procurement chain.

Add Files

Opens an upload interface where users can drag and drop or select files to attach to the procurement chain. Lists previously uploaded files with metadata:

Edit Status

Shows a list of statuses linked to the procurement chain, each with:

| Field | Description |

|---|---|

| Status* | Name of the status (required) |

| Date* | Date and time when status was set (required) |

| Created | Date/time the status record was created |

| Changed By | User who created or updated the status |

| Active Checkbox | Checkbox to mark which status is currently active |

Users can add new statuses via + Add status button.

Any manually created status (added by the user) can also be deleted — a delete icon (×) will be available next to it. System-generated statuses cannot be deleted. These are created automatically by the system, for example:

- New – created after procurement order creation.

- Expected Delivery – generated if the expected delivery date field is filled in.

In such cases, no delete icon is shown.

Changes are saved by clicking the Edit button.

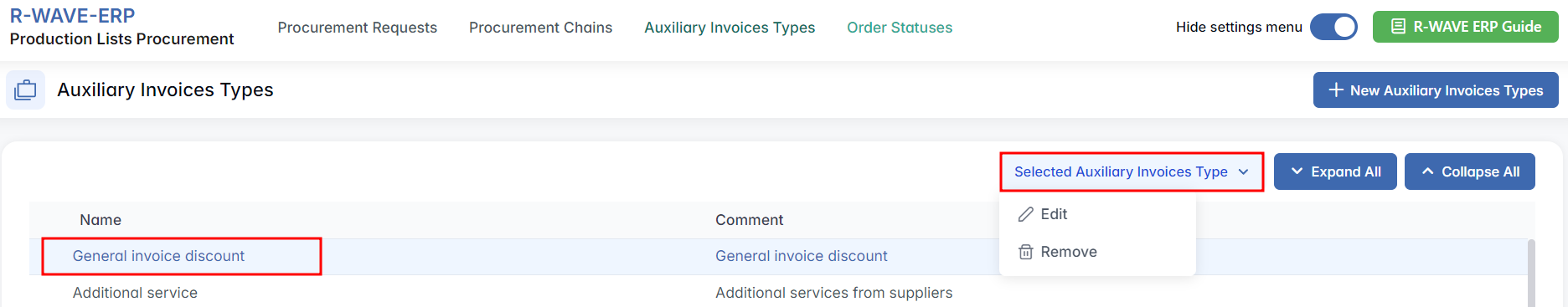

Hidden Settings in Production Lists Procurement

Hidden Settings in Production Lists Procurement

These settings become available when the “Hide settings menu” toggle (top-right corner) is enabled. It reveals two additional configuration tabs:

Auxiliary Invoices Types

This section allows you to define and manage types of auxiliary invoices — used for services or charges not directly tied to material items (e.g., transportation, consultancy, programming). These invoice types are applied when creating auxiliary proforma invoices or invoices within procurement chains.

Functionality:

- Dropdown Selected Auxiliary Invoices Type with options:

- Expand All / Collapse All — manage nested types if present.

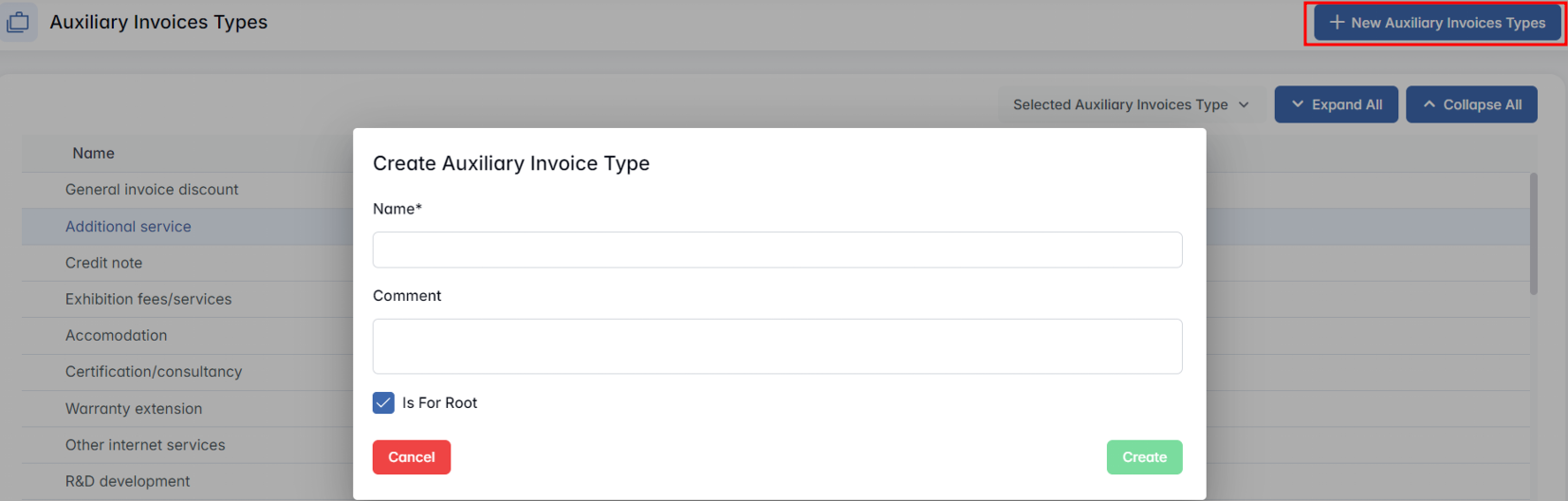

Creating a New Auxiliary Invoice Type

Click the + New Auxiliary Invoices Types to open a modal form with the following fields:

- Name* — the title of the auxiliary invoice type (required).

- Comment — a short description or note.

- Is For Root — checkbox to mark the invoice type as root-related.

Click Create to save the new type. These entries will be available in the procurement chain interface when managing additional service invoices.

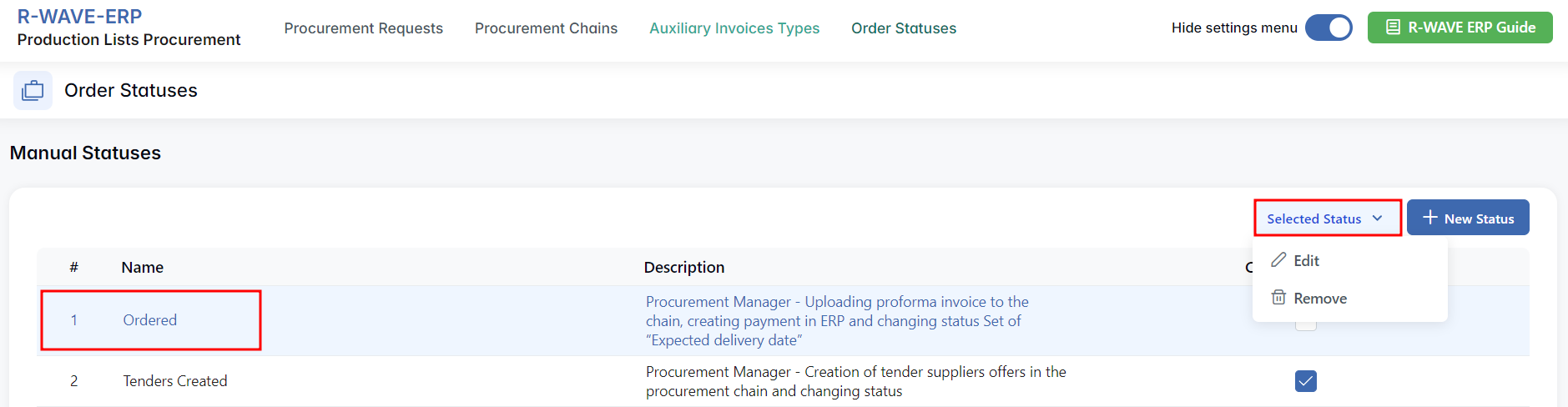

Order Statuses

This section allows you to create and manage manual statuses that track the progression of procurement chains. These statuses help procurement teams monitor and document the full lifecycle of an order, from creation to completion.

Functionality:

- Dropdown Selected Status with options:

- Chain Finish Step — checkbox to designate a status as the final milestone in a procurement chain.

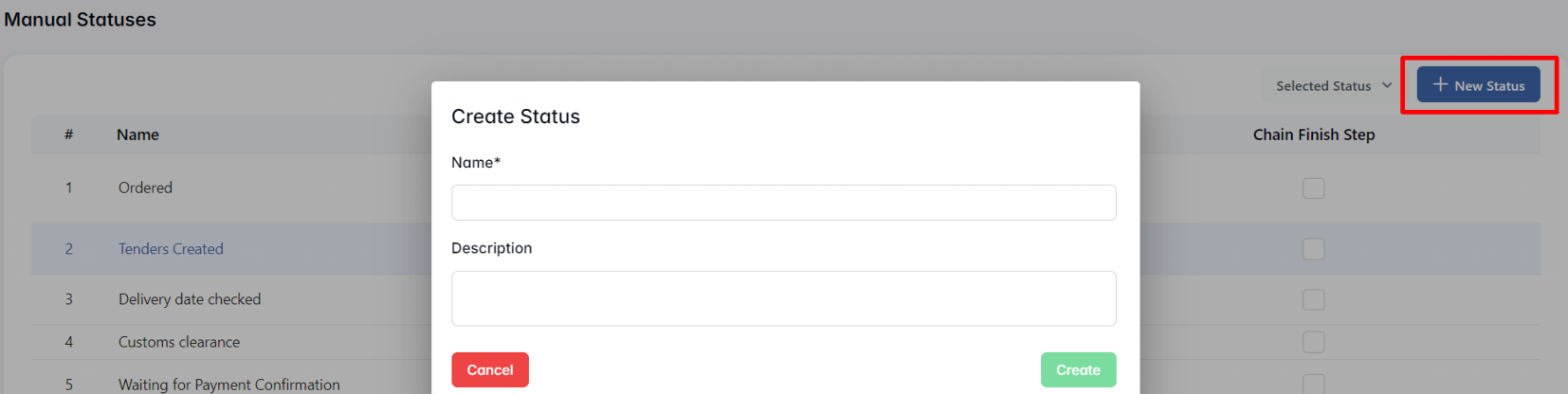

Creating a New Order Status

Click the + New Status button to open the creation form:

- Name* — status name (required).

- Description — optional explanation of the status’s purpose and context.

Click Create to save the new status. Once added, it will appear in the list and can optionally be marked as a Chain Finish Step to signal the end of a procurement chain.