Manufacturing Module

The Manufacturing module in R-Wave ERP enables you to manage the full lifecycle of internal production. It connects product structures with actual production plans, allowing detailed task scheduling, resource allocation, and order tracking.

This module includes the following key tabs:

- Plans – view and manage all active production plans

- Orders to Own Production – manage internal production orders

- Ordered Items List – track all items and components from orders to own production

- Slice Tasks – manage and assign detailed production tasks

It helps your team streamline manufacturing operations, monitor task progress, assign resources efficiently, and coordinate production with warehouse availability.

R-WAVE ERP Guide

R-WAVE ERP Guide

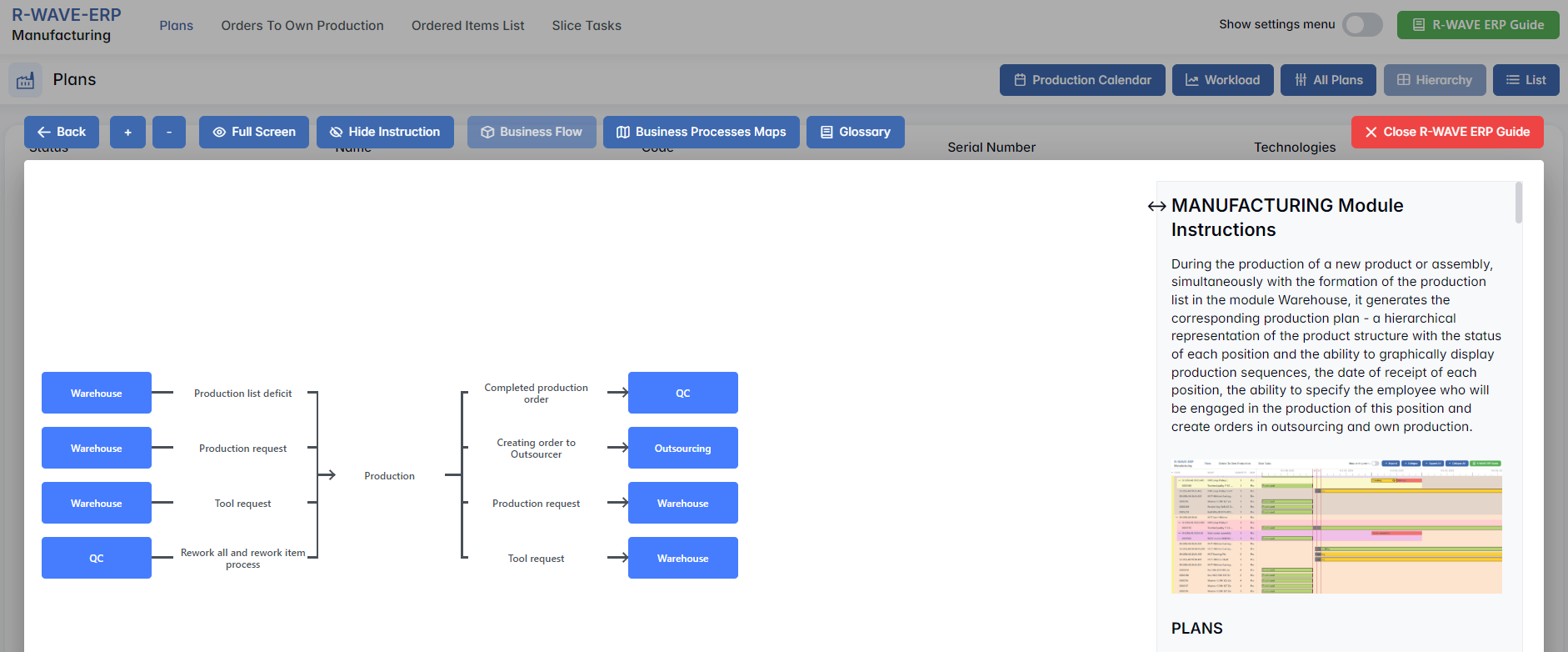

To support user navigation and clarity, R-Wave ERP includes a built-in contextual help system in the form of a pop-up guide window. This feature is available across different modules, including Manufacturing, and is designed to help users understand where they are in the system and how to use the current section effectively.

The ERP Guide window helps users by:

- Showing where you are within the system (module context).

- Providing a visual schema of your company’s business flow, helping you understand how the current module fits into the larger operational structure.

- Offering a quick-reference instruction panel with the main actions and functions available in the current tab (e.g., creating companies, filtering, scheduling events).

Layout and Content

When opened, the ERP Guide window is divided into two main areas:

- Left Side — Business Flow Map

This section displays a structured diagram of your company's processes and how the current module connects to others (e.g., CRM, Procurement, Sales, HR). It visually highlights your current position in the overall ERP environment. - Right Side — Functional Overview

Provides a concise, bullet-style instruction list describing the key operations available in the current module/tab.

Top Bar Options

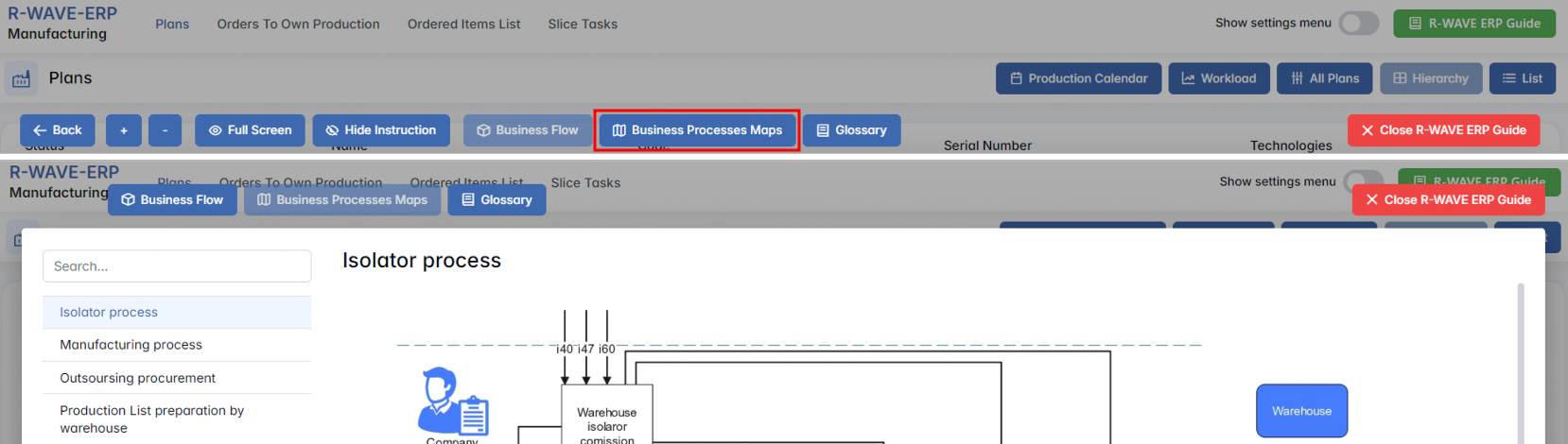

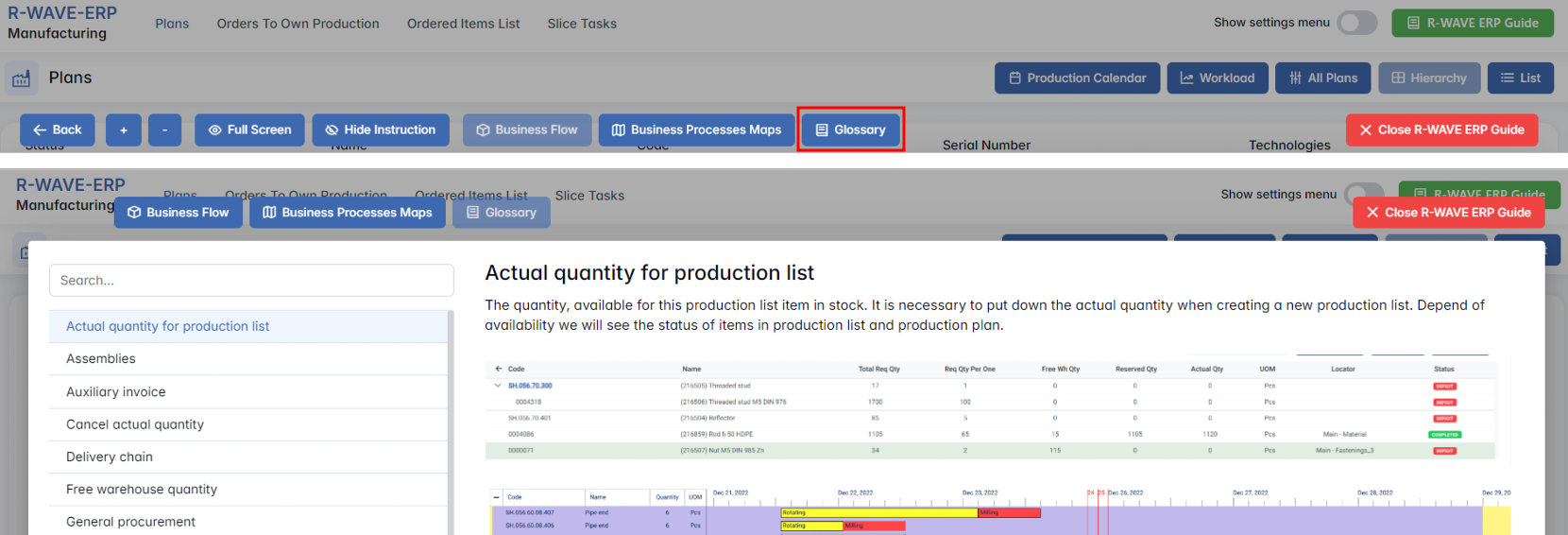

At the top of the ERP Guide window, you’ll find two optional tools for deeper understanding:

- Business Processes Maps – Opens a full interactive view of your organization’s process structure.

- Glossary – Provides definitions and descriptions of key terms and field labels used in the ERP interface.

The ERP Guide window can usually be opened via a dedicated icon or help button (often located in the upper right corner of the screen). It is non-intrusive and can be closed or reopened as needed, allowing users to stay focused without losing their place.

Manufacturing Module Overview

Plans

Plans

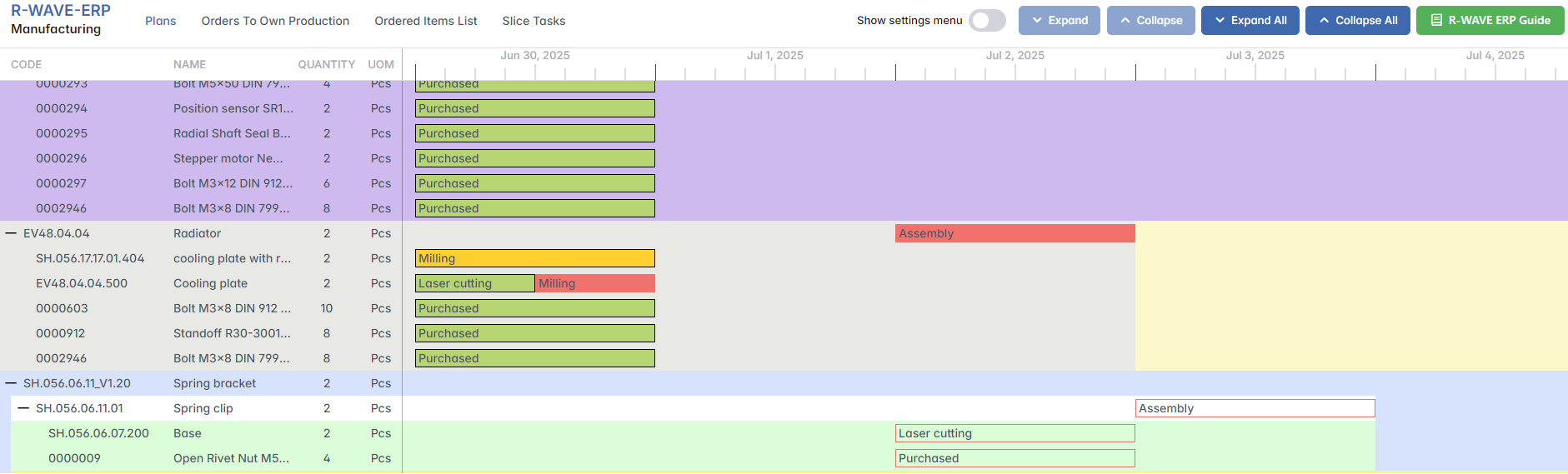

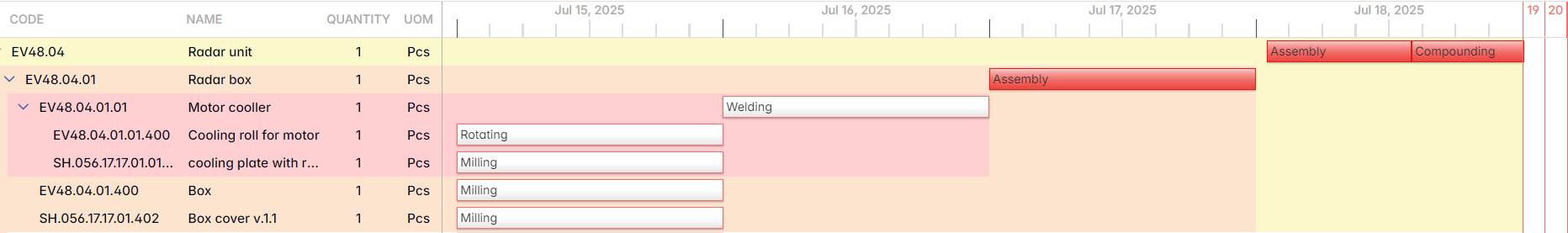

The Plans tab in the Manufacturing module displays all currently active production plans. Each plan represents a structured and visualized version of product structure sent to production. These plans are generated automatically based on the corresponding production structure.

Purpose of the Plans Tab

This tab allows users to:

- View, filter and manage current production plans;

- Monitor the production status of each position in the hierarchy;

- Visually schedule tasks and assign employees or machines;

- Create production orders (Own or Outsourced);

- Add or remove positions from the plan and track their warehouse status;

- Manage changes and rework requests dynamically.

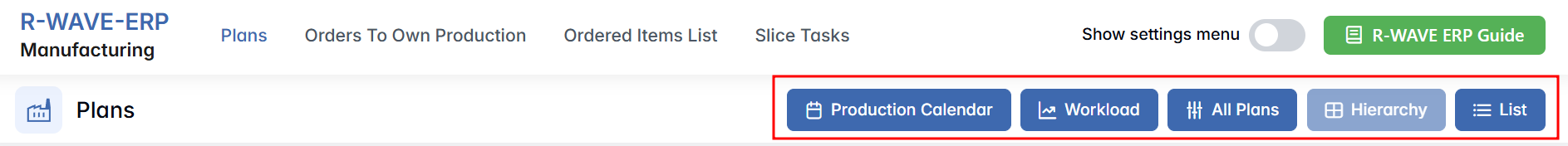

Interface Overview

Upon entering the Plans tab, the user sees:

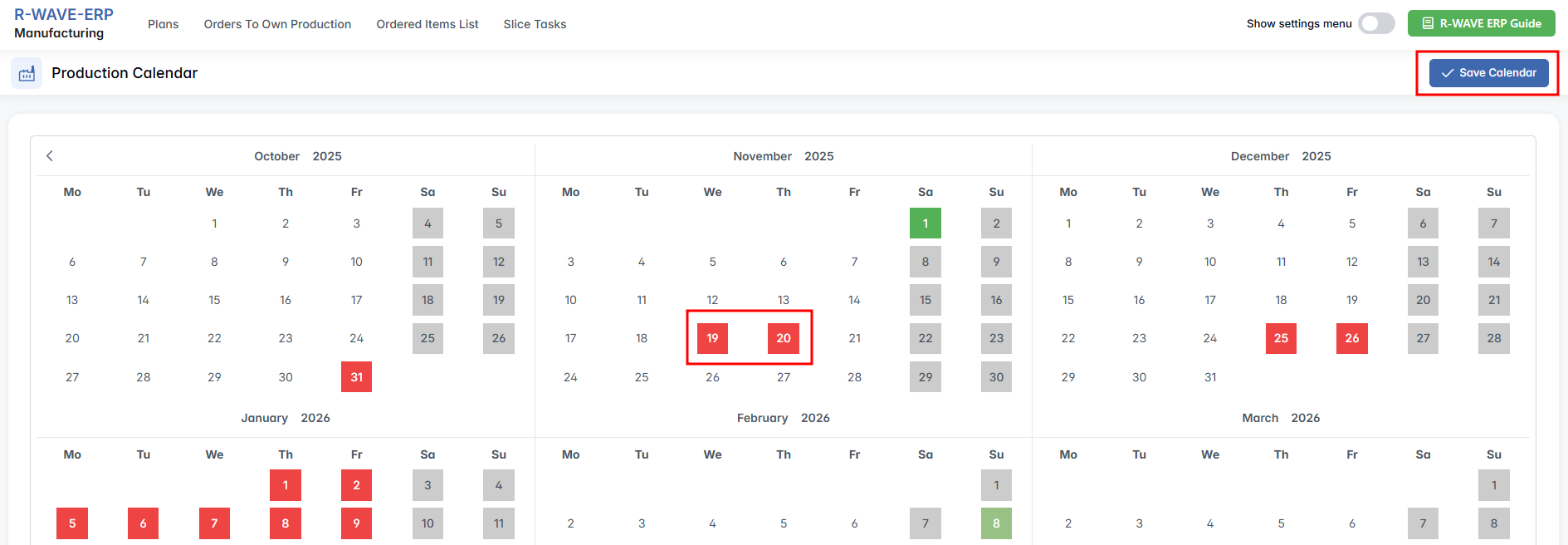

Production Calendar

Opens a separate calendar interface where you can mark holidays and non-working days. After making changes, click the Save Calendar button to apply them to the system.

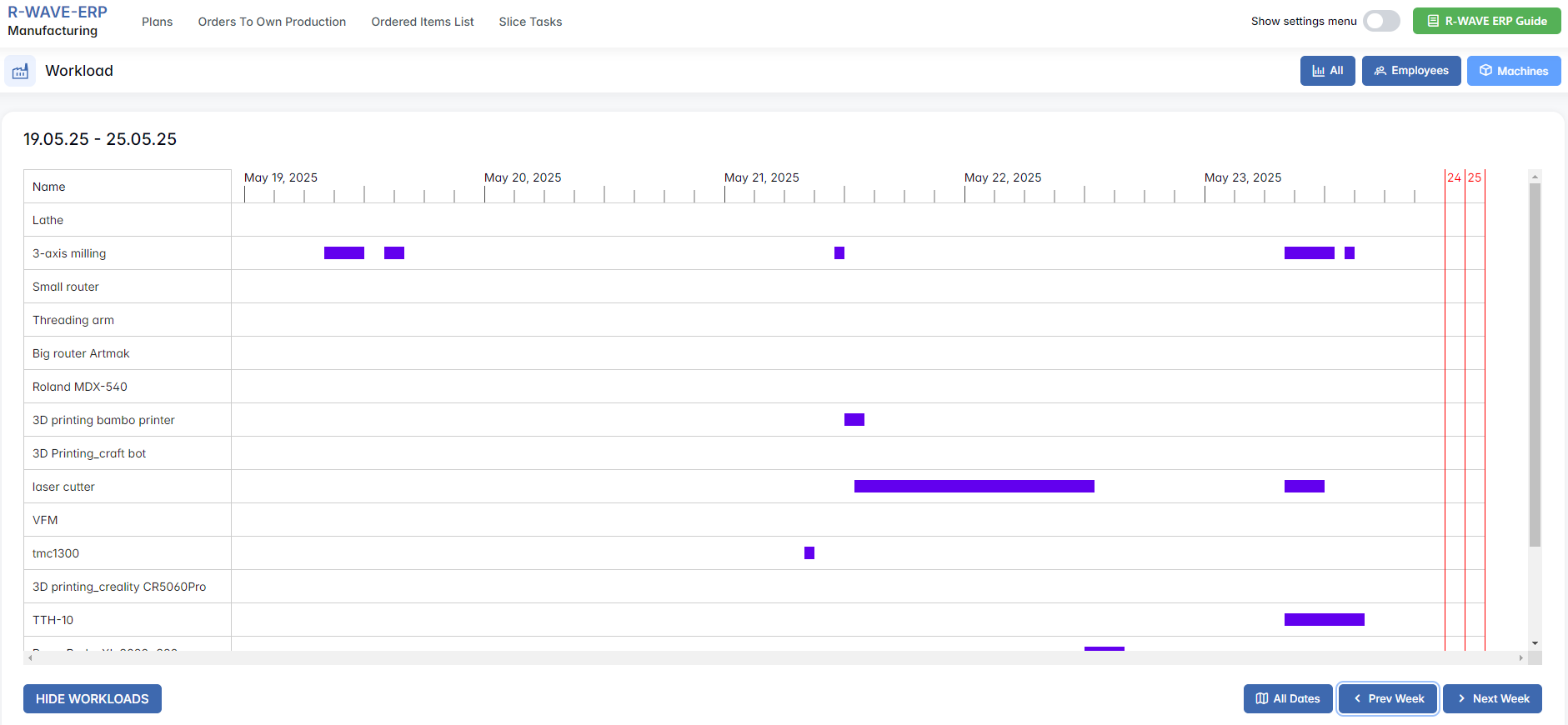

Workload

Displays a weekly or full-range timeline showing how tasks are distributed across: Employees, Machines or All

Rows list employees/machines, columns represent time.

Controls:

- Prev / Next Week – scroll the timeline

- Slider – jump to a specific time frame

- Hide Workloads – activates checkboxes to manually hide irrelevant rows

All Plans View

A consolidated color-coded view of all production plans in the system.

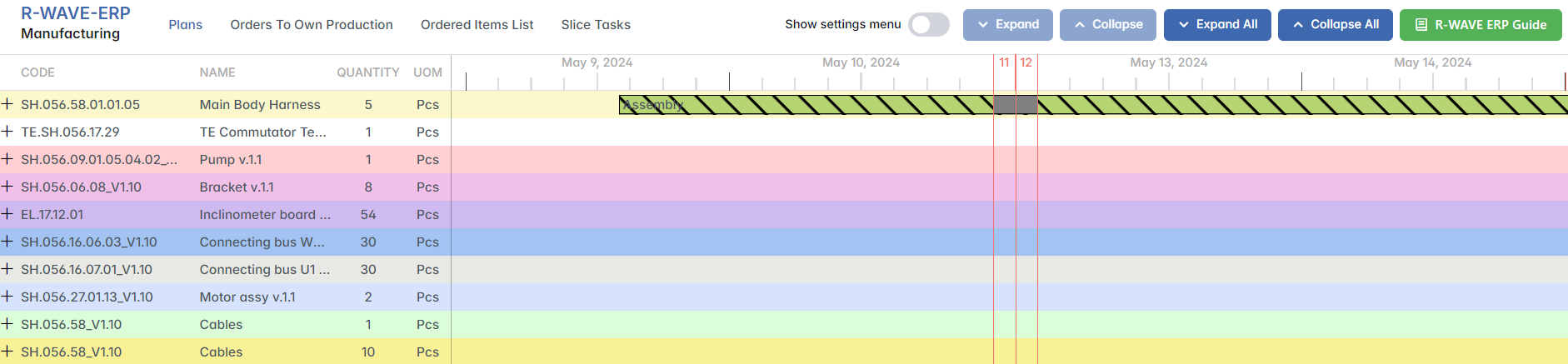

Hierarchy – switches to a hierarchical tree view of the plan, showing the product structure categories and levels.

List – switches to a flat list view of all plans.

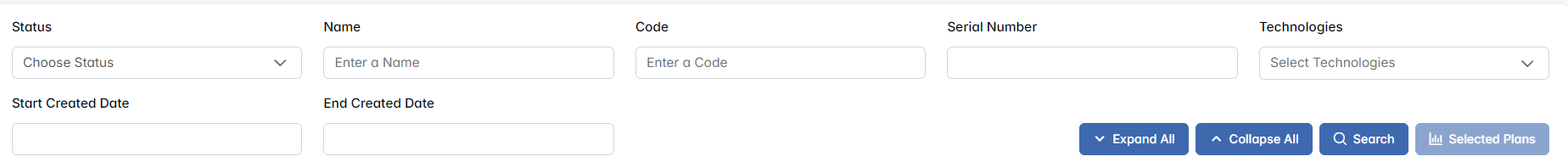

Filter Panel

Includes filters for narrowing down plans by:

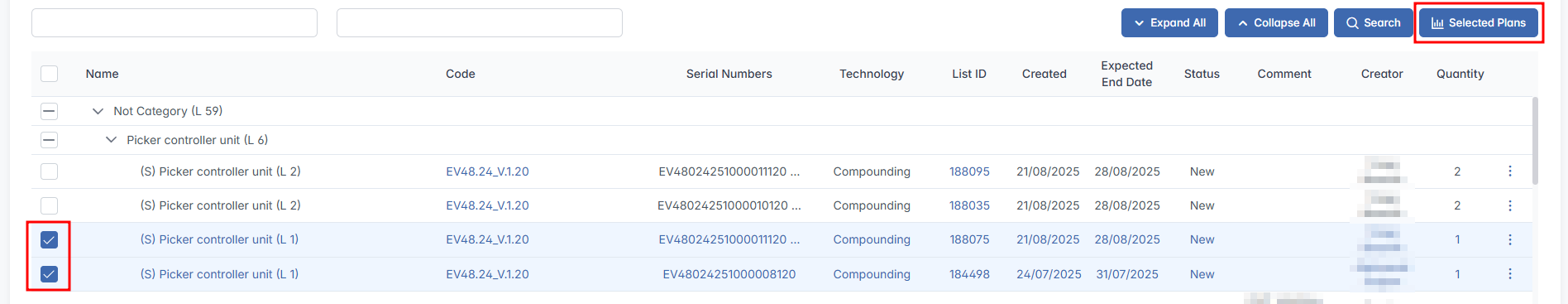

- Expand All / Collapse All – for hierarchical view

- Search – quick search bar

- Selected Plans – This option becomes active when one or more rows are selected (multi-selection is supported). It opens the selected plan(s) in a separate window.

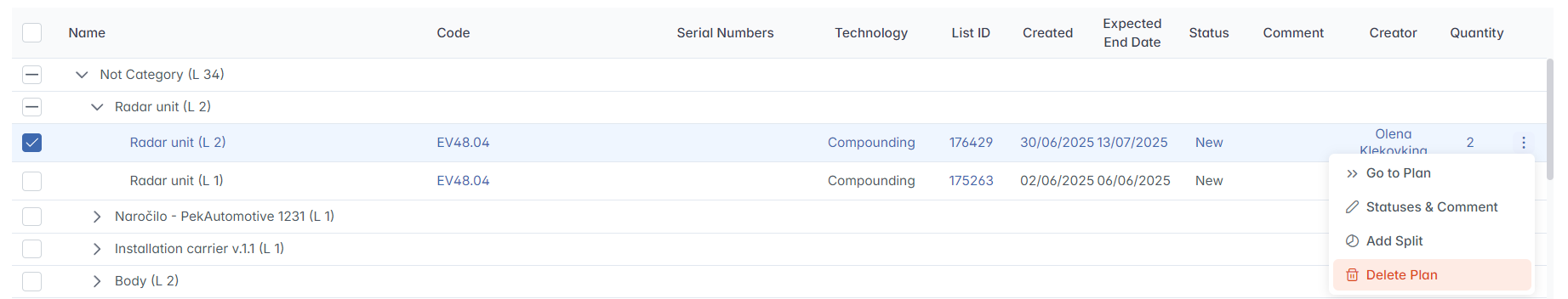

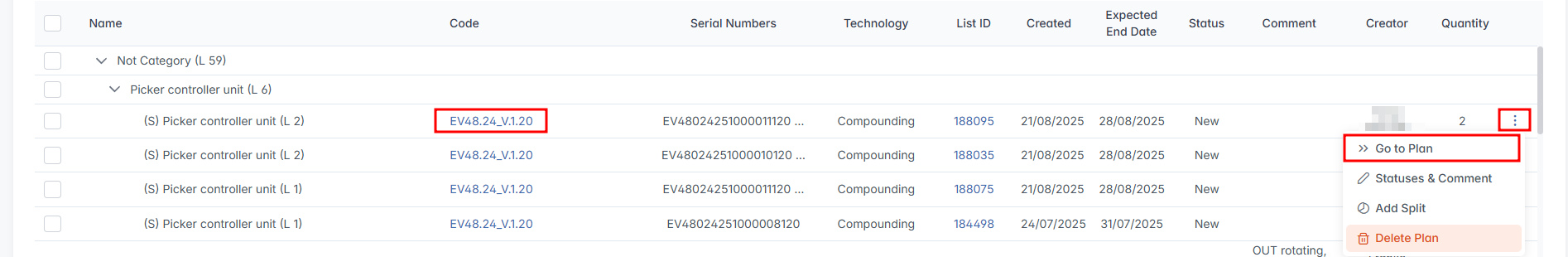

Row Actions (click on ⋮ icon at end of row):

Actions Explained

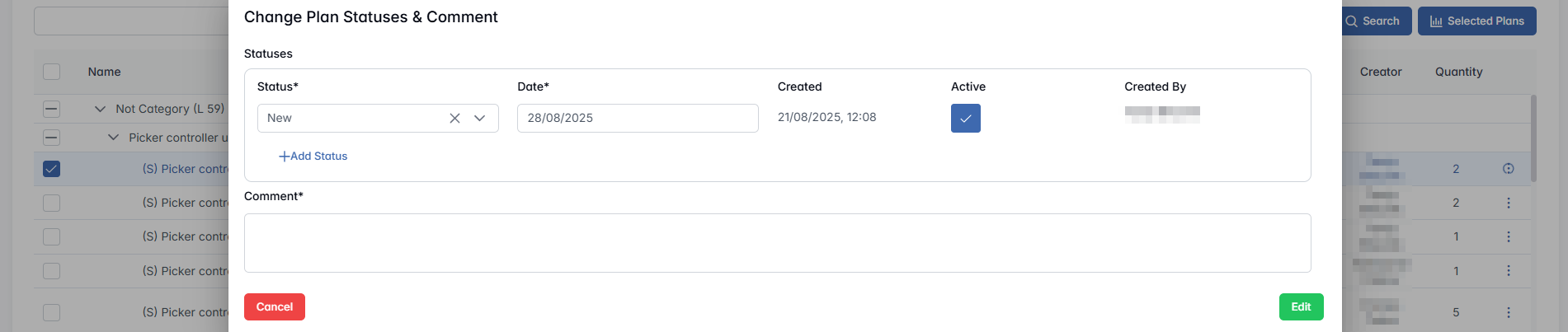

Statuses & Comment – opens a modal where you can track or update the progress. You can add multiple statuses by clicking + Add Status, but only one can be marked as Active at a time. The Comment field is optional.

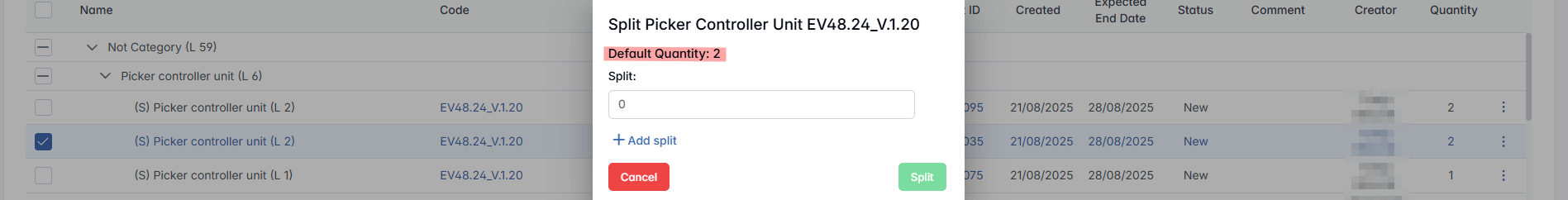

Add Split – available if quantity > 1, allows splitting into separate plans, but the total amount must be equal to the initial quantity. For example, if the total quantity is five, the split can be 2, 2, 1.

Delete Plan – allows you to remove the plan at any stage. If the plan includes positions linked to open orders or warehouse requests, those connections will be automatically removed during deletion

Go to plan – opens the detailed plan page.

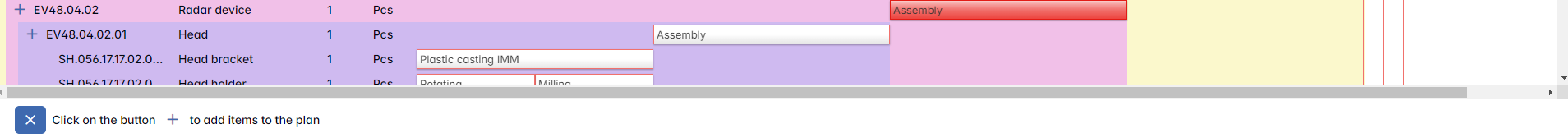

Here, you see a hierarchical tree, showing all positions, their statuses, and production tasks.

Colored graphical markers next to each position:

You can also access the plan page by clicking the Code value in the table on the main Plans page — it is clickable and leads to the same detailed view.

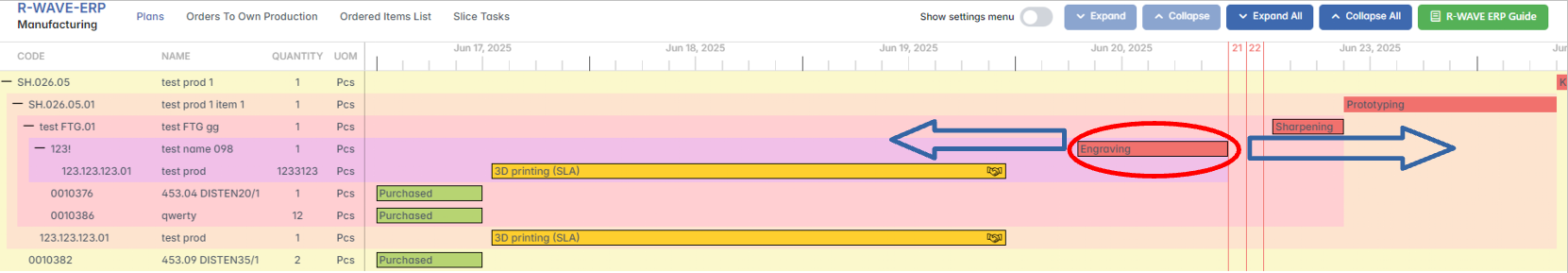

Calendar & Gantt Area

At the top of the plan view is the production calendar, which shows a timeline of expected delivery dates and manufacturing stages. The Gantt-style chart lets users:

- Drag bars left or right to change expected start/end dates of tasks

- Click on a task bar to open a pop-up for:

When delivery date of a child item is changed, the parent item’s delivery schedule shifts accordingly. The schedule always respects the hierarchy.

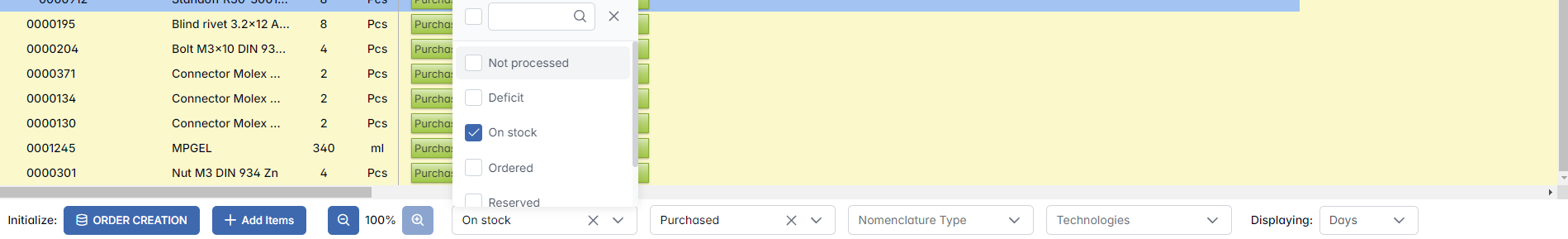

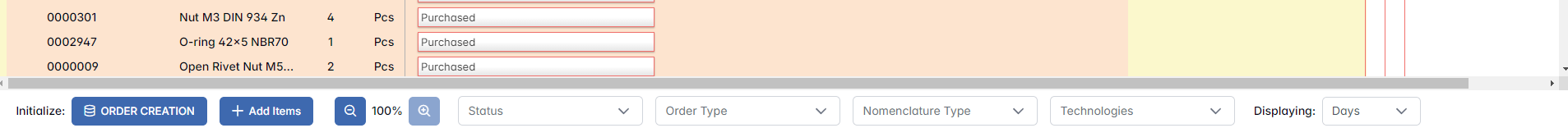

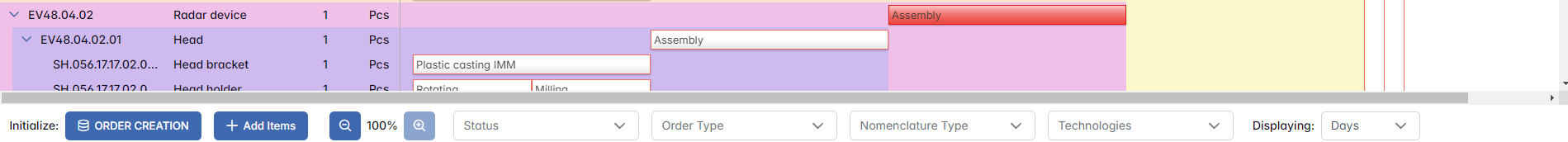

Filter Panel (Bottom of the Plans Page)

- Status – Not processed, Deficit, On Stock, Ordered, Reserved, Rework

- Order Type – Own Production, Outsourcing, Purchased

- Nomenclature Type – Assembly, Manufactured, Purchased

- Technologies – Filters by technology (e.g., Assembly, Welding, Compounding, Rotation, etc.)

Filter Interaction Principles

Filters work combinatorially. The more filters you apply, the narrower the visible result.

Some examples:

- If you select Order Type: Purchased + Status: Deficit — you might see nothing, because the purchased item wasn’t ordered.

- If you select Technologies: Welding + Nomenclature: Manufactured — you'll get only those manufactured items that include welding.

- If you select Order Type: Own Production and filter Status: On Stock — you’ll see only manufactured items that were produced internally and are now ready.

Some filters are context-sensitive. For example, if no positions are using the “Rotation” technology, the filter will show zero results.

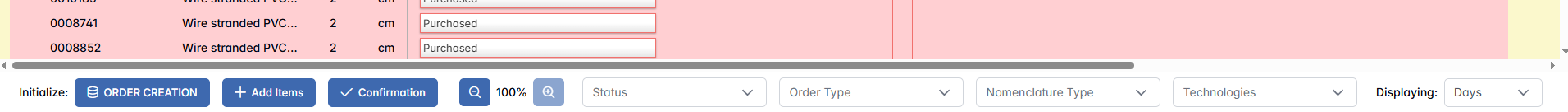

Actions in the Bottom Panel

In addition to filtering, the bottom panel also includes action buttons:

- Order Creation — Starts the order creation flow for selected tasks

- Add Items — Allows adding new items to the plan from stock

- Confirmation – sending a request for planning confirmation/correction to confirm the existing or the changed plan

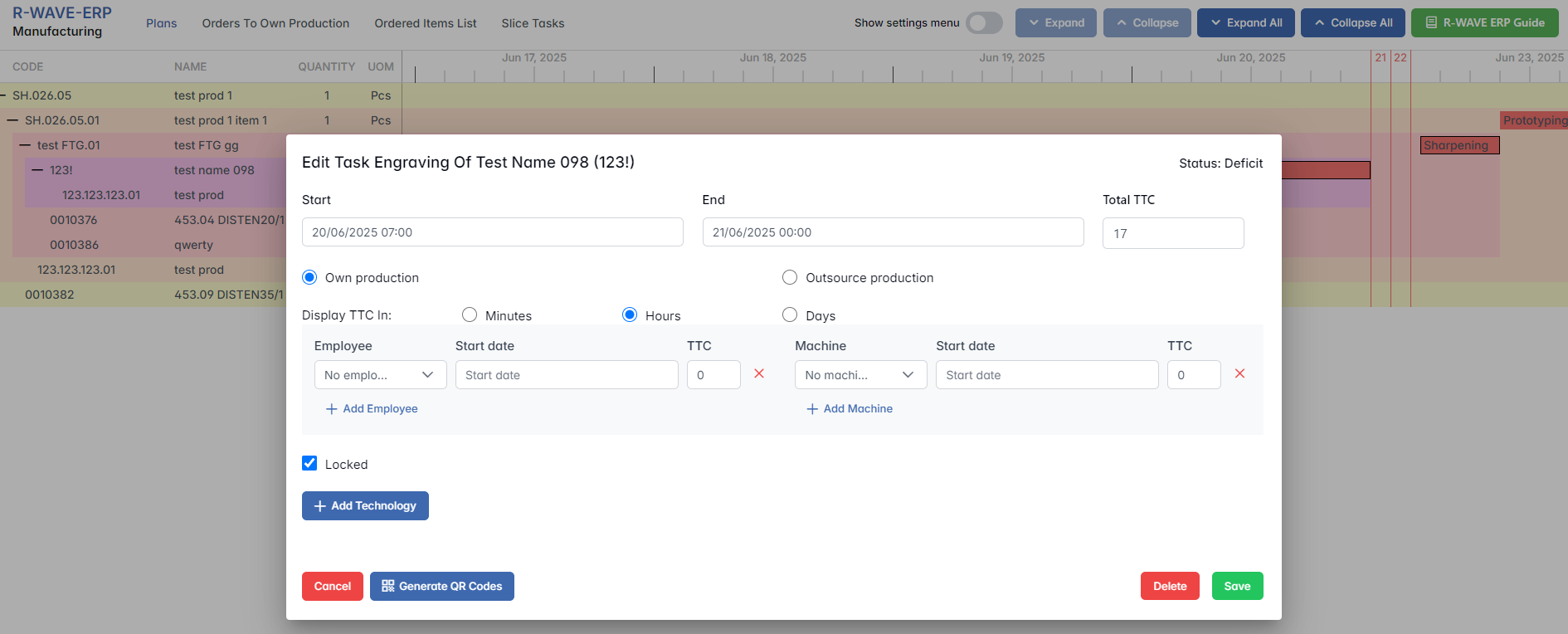

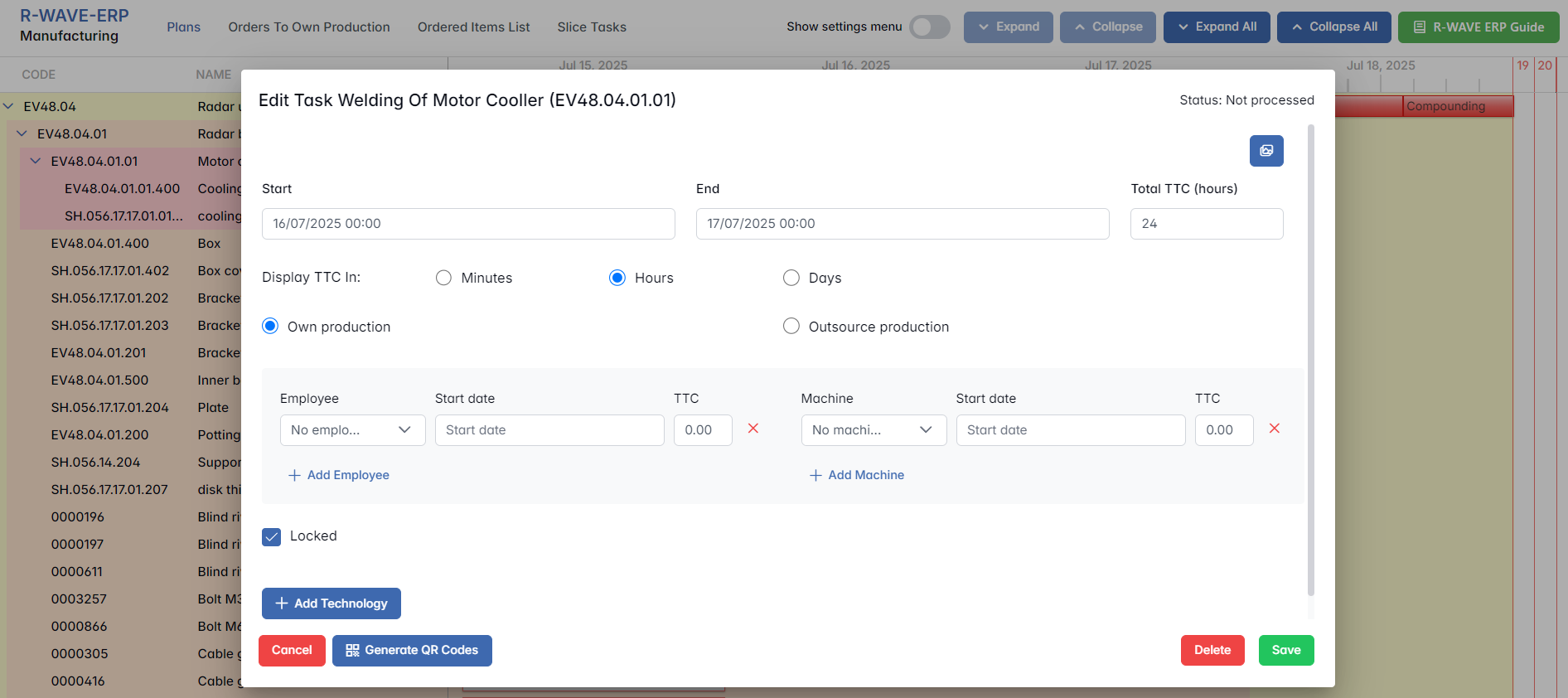

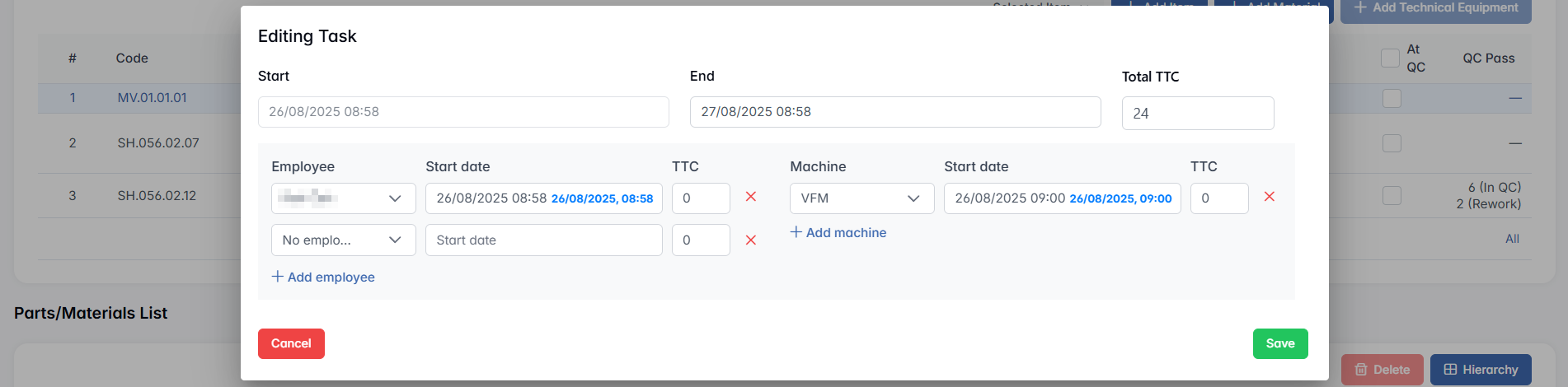

Task Interaction: Editing and Assignment

When clicking on a specific task in the Gantt chart, a pop-up window opens. Here the user can:

- Drag to reschedule OR manually enter Start/End date and time

- Insert TTC (time to complete)

- Choose the type: Own production or Outsource

- Assign:

- Employees (and their time allocation)

- Machines

- See if the task is Locked or Unlocked (or you can (un)lock it manually)

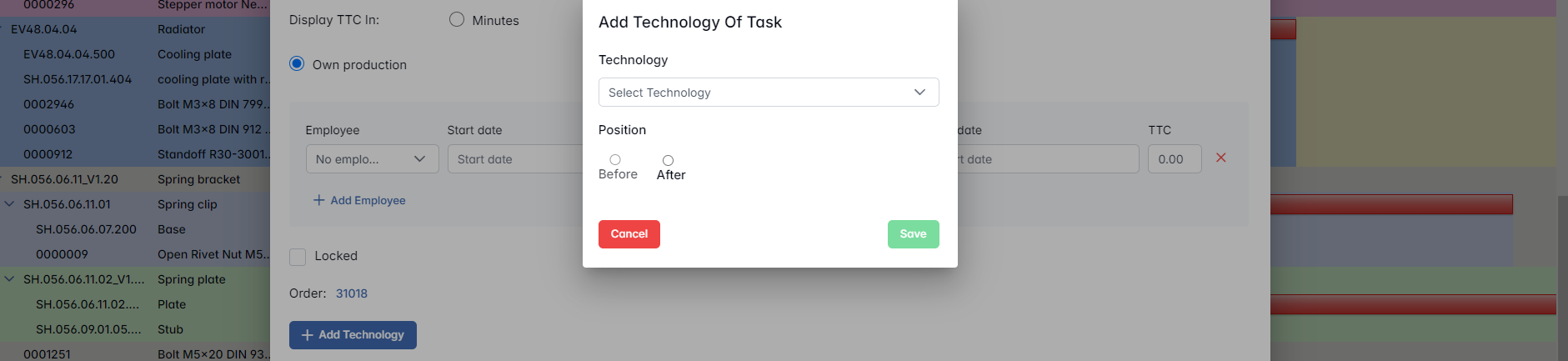

- Add Technology

Employee and machine assignments are only available for Own Production orders.

Creating Orders from the Plan

Once unlocked, tasks can be selected and included in a production order:

- Click Order Creation

- Choose technologies from the 1st and 2nd filters (only sequentially)

- Click Create Order

The system generates a new order and also a Production Request (for Own) or Delivery Request (for Outsourcing).

Restrictions:

- Order can include only DEFICIT and Unlocked tasks

- Cannot mix Own and Outsource in one order

- Tasks must follow the technology sequence

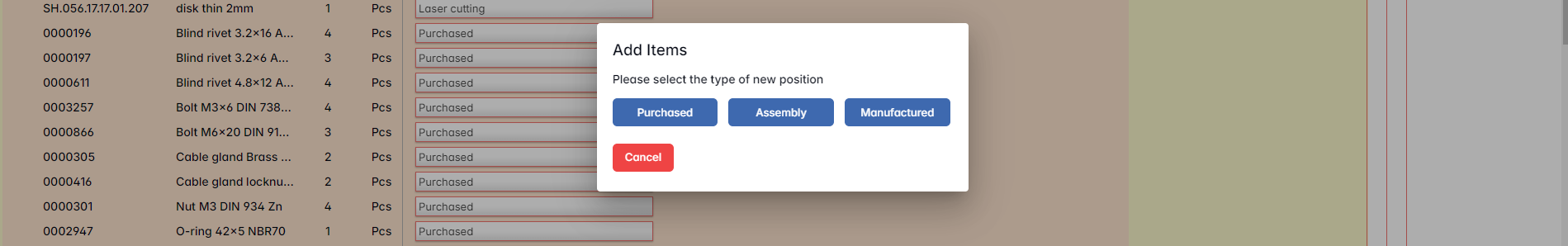

Adding Items to the Plan

You can add items to an existing plan without changing the original Product Structure. Steps:

- Click Add Items

- Choose item type (Assembly / Manufactured / Purchased)

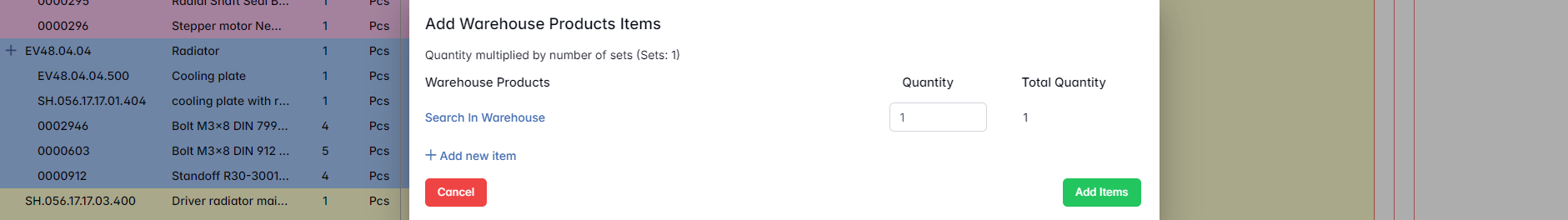

Purchased:

Purchased:

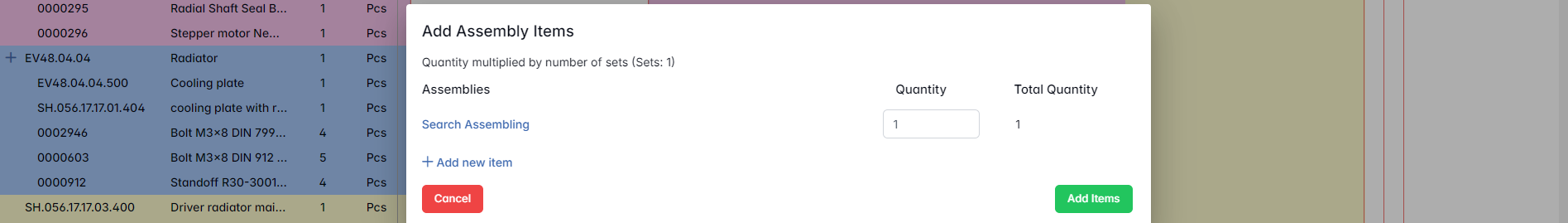

Assembly:

Assembly:

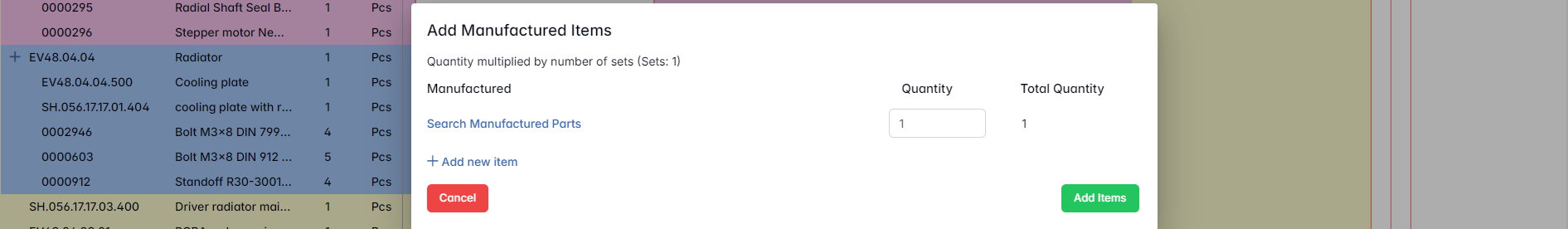

Manufactured:

Manufactured:

- Search in Warehouse/Assembling/Manufactured items or Add new item

- Enter quantity per item

- Click Add Items

When you click Add Items, the selected materials or components are added to your production plan. Here's how it works:

- Status Assignment

Every new item you add will automatically be assigned the status Not Processed. This means the system recognizes the item as pending action — either to be picked from the warehouse, purchased, or manufactured — but no sourcing process has started yet.

- Warehouse Check Required

Availability of each item must be checked manually in the warehouse. The system will not automatically reserve or check inventory levels. This ensures that warehouse managers or planners have full control over what is picked or requested.

- How to Proceed After Adding

Once the items appear in the plan with the status Not Processed, it’s up to you or the warehouse team to: Check if the item is available in stock. If it’s not available, initiate one of the following manually via the Production List module:

For purchased items: create a purchase request.

For manufactured items: create a manufacturing task.

Quantity per assembly is automatically multiplied by the number of assemblies in the plan.

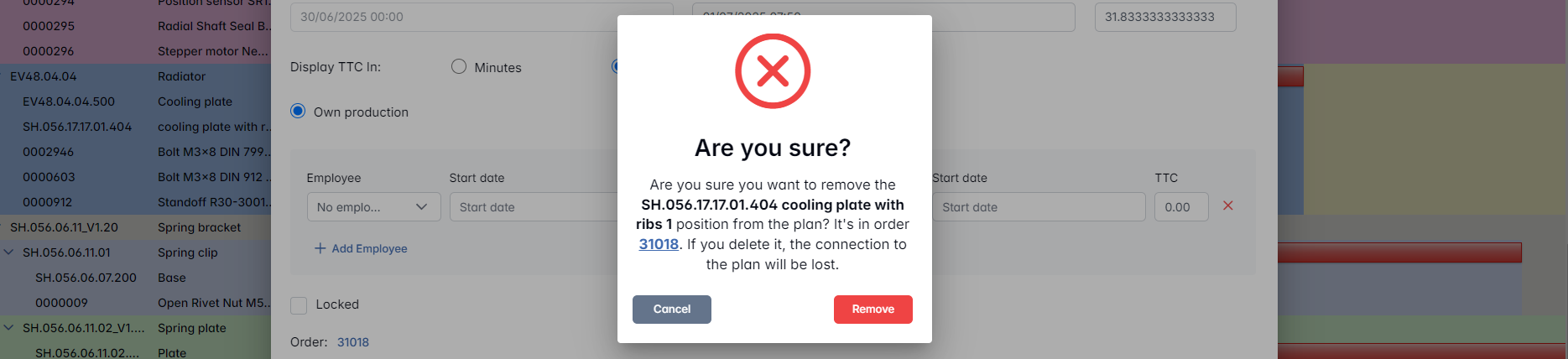

Deleting Positions

To delete a position:

- Click the task bar of the position

- Click the Delete button in the pop-up

Behavior:

- If the position is not linked to any open order or warehouse request:

- A confirmation modal appears asking the user to confirm deletion.

- If it’s linked to an open order:

- System asks for confirmation and unlinks the order (order remains in system)

- If warehouse request is already closed:

- Deletion is blocked — action denied

Deleted positions are returned to Warehouse – Items.

Order Dependencies

- If a new item is added to a position that is already included in an order:

The added item will appear in that order’s Parts/Materials List and in the Warehouse – Production Requests menu for preparation.

- If an item is deleted from a position that has already been sent to an order:

The item will be removed from both the order’s Parts/Materials List and the associated warehouse request — but only if the production request has not yet been closed.

- If the related warehouse request is already closed:

The item cannot be deleted from the plan, and the system blocks the action.

- If a user attempts to delete a plan that contains ordered items:

A confirmation modal appears listing the affected items. For example: “Are you sure? The assembly you want to delete contains the ordered items: 1. 0000371 Connector Molex MX150 male 2 rows 20 circuits black (33482-2101)”

If the user confirms, the plan is deleted, and the related order is unlinked — but the order itself remains in the system and can be managed independently. These mechanisms ensure that production and warehouse data remain aligned with real-time changes in the plan.

Unlocking and Manual Order Creation

In the Manufacturing module, tasks in the production plan can only be included in an order if they are unlocked. Unlocking signifies that a task is eligible for ordering and meets specific readiness requirements. Tasks can then be unlocked — either automatically or manually — based on the production needs.

Unlocking

- Automatic Unlocking

A task becomes unlocked automatically when one of the following conditions is met:

Tasks that meet these conditions are automatically marked as unlocked in the plan and are eligible for ordering.

- Manual Unlocking

If not all materials or dependencies are ready, but production must proceed, the user can manually unlock a task to enable partial order creation.

This is useful for:

Manual unlocking overrides dependency checks — use only when partial readiness is acceptable.

Order Creation Logic

Once a task is unlocked, the user can initiate the order creation process by clicking the Order Creation button.

- Preconditions for Order Creation:

- Task status must be DEFICIT.

- Task must be unlocked (either automatically or manually).

- Technologies must follow the correct sequence (no skipping steps).

- Technologies Selection:

- The first filter displays the next available technology for each item (based on prior steps being already ordered or completed).

- The second filter shows all valid subsequent technologies for the selected items, allowing creation of multi-step orders (e.g., Welding + Painting).

Skipping technologies is not allowed. The sequence must remain consistent.

- Selection Requirements:

- At least one task must be marked with “Add to Order” checkbox to proceed.

- Only sequential technologies can be grouped in one order.

Create Order Modal

After selecting tasks and clicking Create Order, a modal window opens for order planning. The following parameters can be adjusted:

- Order Type: Own Production or Outsourcing

- Task Schedule: Start/end time (automatically initialized but editable)

- Employee and Machine Assignment (only for Own Production orders)

Restrictions:

- Start time of any task or resource cannot be earlier than the order creation time.

- Outsource orders do not allow employee or machine assignment.

- A single order cannot mix Own and Outsource types.

- Conflicting schedules trigger a warning with options to adjust or continue.

Materials and Subassemblies Handling

The system includes components in the Parts/Materials List and Subassemblies section of the order, based on the readiness and structure of the task:

- If the task was automatically unlocked:

- All ON STOCK child components are added to Parts/Materials List

- No further breakdown is performed — components are treated as ready-to-use

- If the task was manually unlocked:

- All available materials are added to the Parts/Materials List

- All deficit subassemblies are added to Subassemblies

- Already ordered subassemblies are listed again and await completion

- The deficit child tasks of this unlocked task become blocked for separate ordering (to avoid duplication)

Special Notes:

The system adjusts start/end dates of tasks automatically to preserve correct sequences.

Technical Equipment (if assigned to the technology) is automatically added to the order and included in the Production Request.

All tasks in a single order:

- Share the same status

- Are shown in the plan with the same color

- Are linked together for traceability

- If Outsourced, are marked with a handshake icon

Orders to Own Production

Orders to Own Production

The Orders to Own Production tab in the Manufacturing module of R-Wave ERP is designed to manage and monitor production tasks that are handled internally, within your own facilities. It provides full visibility into the current status of each internal production order, tracks all related components and materials, and ensures alignment between planning, execution, and warehouse operations.

Purpose of the Orders To Own Production Tab

This tab is where all internal production orders are listed and managed. Each record represents an individual production order created from a plan (or several plans) and includes its progress status, associated product, materials, and responsible employees or machines.

The main purpose is to:

- Track the production flow of in-house manufactured items,

- Monitor the availability and use of materials/components,

- Assign employees, or machines to production orders,

- Interact with the Warehouse module (to request materials),

- Pass finished items to Quality Control (QC),

- Ensure every stage of the in-house production cycle is transparent and controllable.

Interface Overview

Upon entering the Orders to Own Production tab, users will see the following interface components:

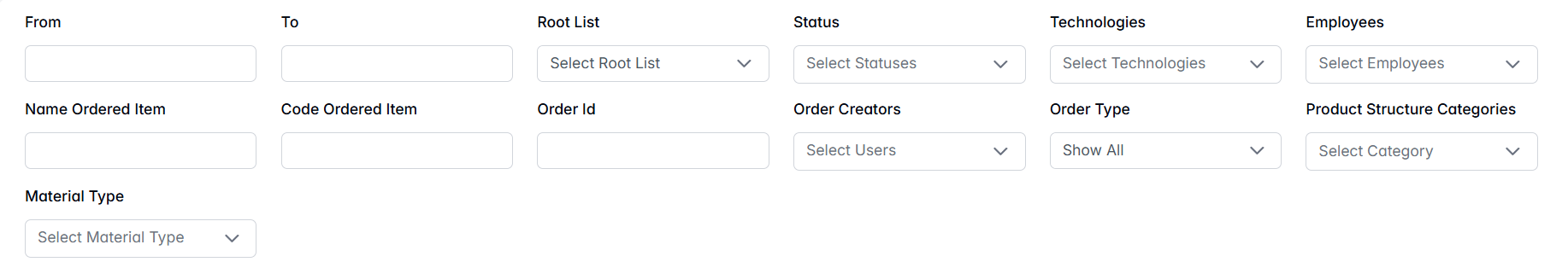

Filter Panel

Located at the top of the page, the filter panel allows users to narrow down production orders using the following parameters:

- From / To – Filter by order creation date range.

- Root List – Filter by originating production plan.

- Status – Multi-select list of order statuses.

- Technologies – Filter by associated manufacturing technologies.

- Employees – Multi-select filter for responsible employees.

- Name Ordered Item / Code Ordered Item – Search by ordered item name or code.

- Order ID – Direct search by order identifier.

- Order Creators – Multi-select list of users who created the order.

- Order Type – Filter to show all orders, only service orders, or only plain (internal) orders.

- Product Structure Categories / Material Type – Filter based on product hierarchy or material classification.

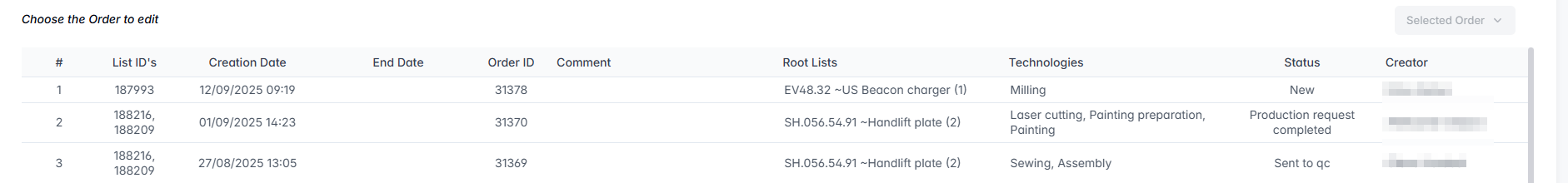

Orders Table

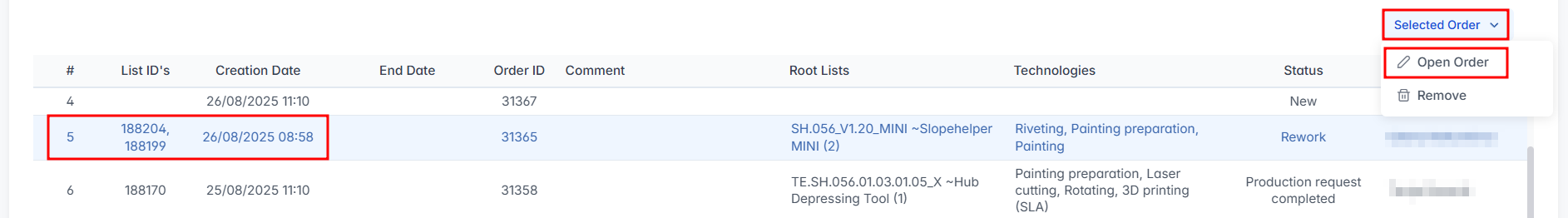

Below the filter panel, the system displays a table listing all matching production orders. Each row represents an individual order and includes the following data:

| Column | Description |

|---|---|

| List ID's | IDs of the originating production plans |

| Date / End Date | Start and end dates of the order |

| Order ID | Unique identifier of the order |

| Comment | Optional internal notes |

| Root Lists | Associated plan(s) from which the order was created |

| Technologies | Technologies involved in production |

| Status | Current state of the order |

| Creator | User who created the order |

Order Status Definitions

Each production order has a status indicating its progress:

- New – A newly created order that has not yet been processed.

- Production request completed – The warehouse has prepared the requested materials and sent them to production.

- Sent to QC – The finished items have been sent to the quality control department.

- On stock – The items have successfully passed QC and moved to warehouse stock.

- Rework – Items failed QC or need modification and have returned to production.

- Cancellation – The order was canceled and will not proceed.

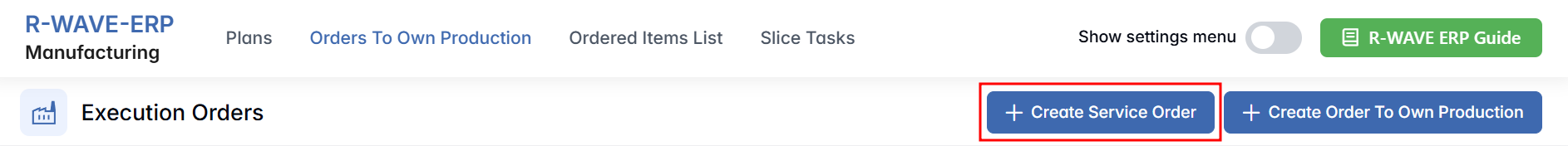

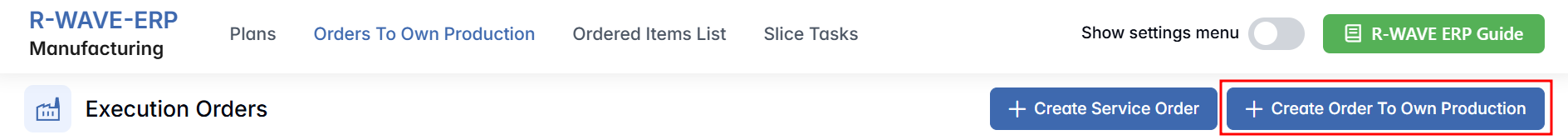

Creating New Orders

In the upper-right corner of the Orders to Own Production page, two buttons are available:

- Create Service Order – Opens a new automatically generated blank order page (e.g., Order #31026). This page allows the user to add service items, create a documentation archive, and send items to QC.

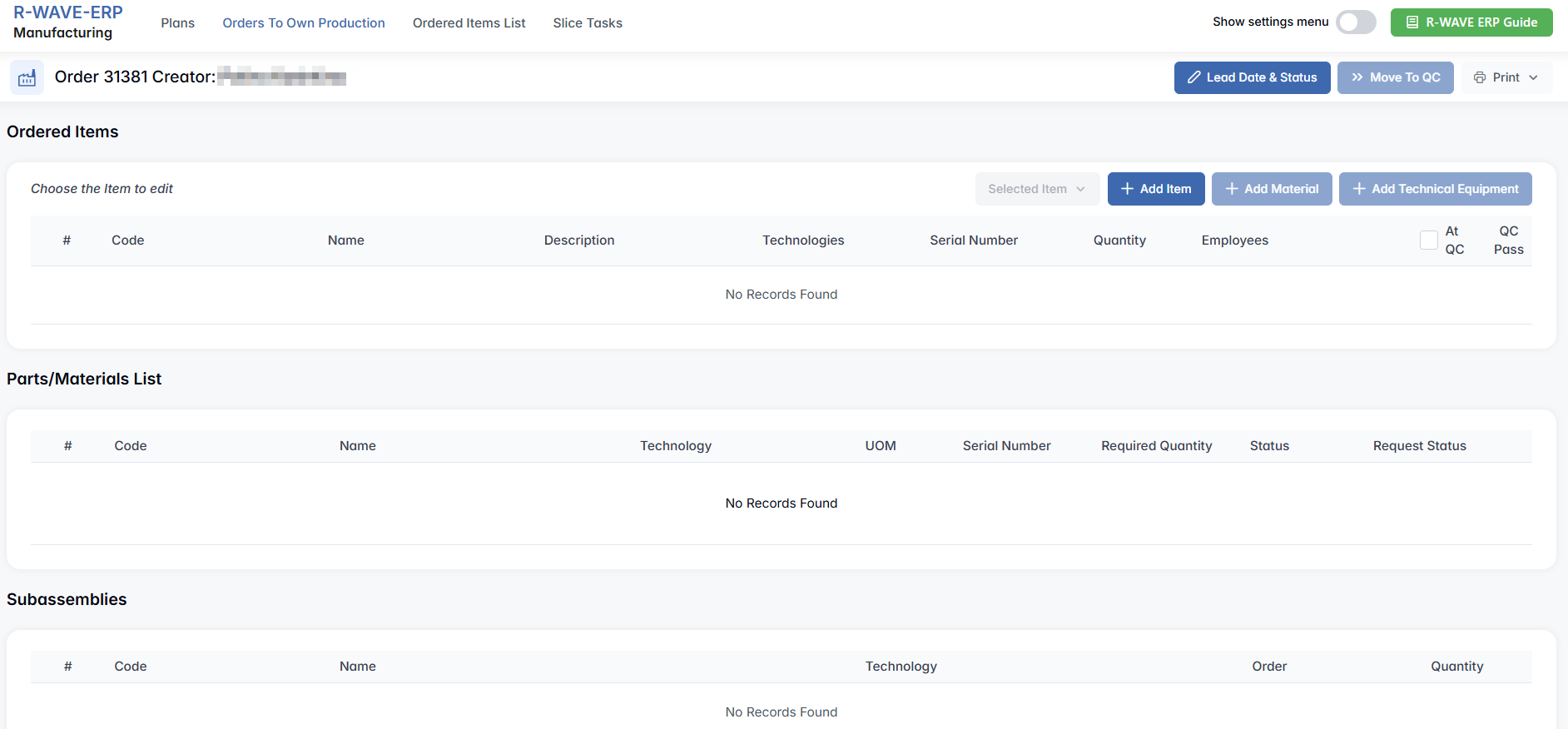

- Create Order to Own Production – Opens a new automatically generated order page similar to the service order, but more detailed. It includes the following tabs: Ordered Items, Parts/Materials List, Subassemblies, QC Intermediate Points, Machines, Technical Equipments, and Manufactured Documentation.

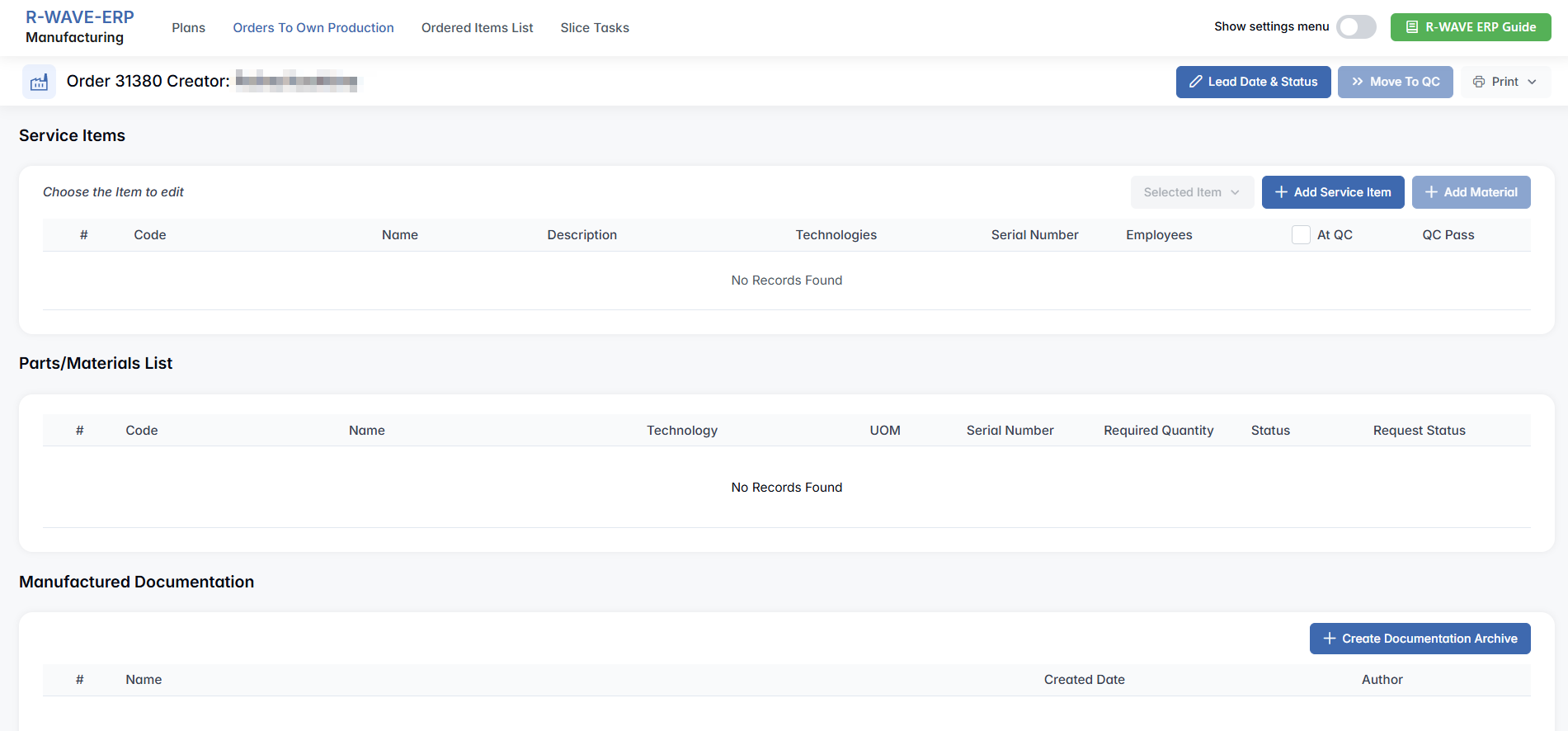

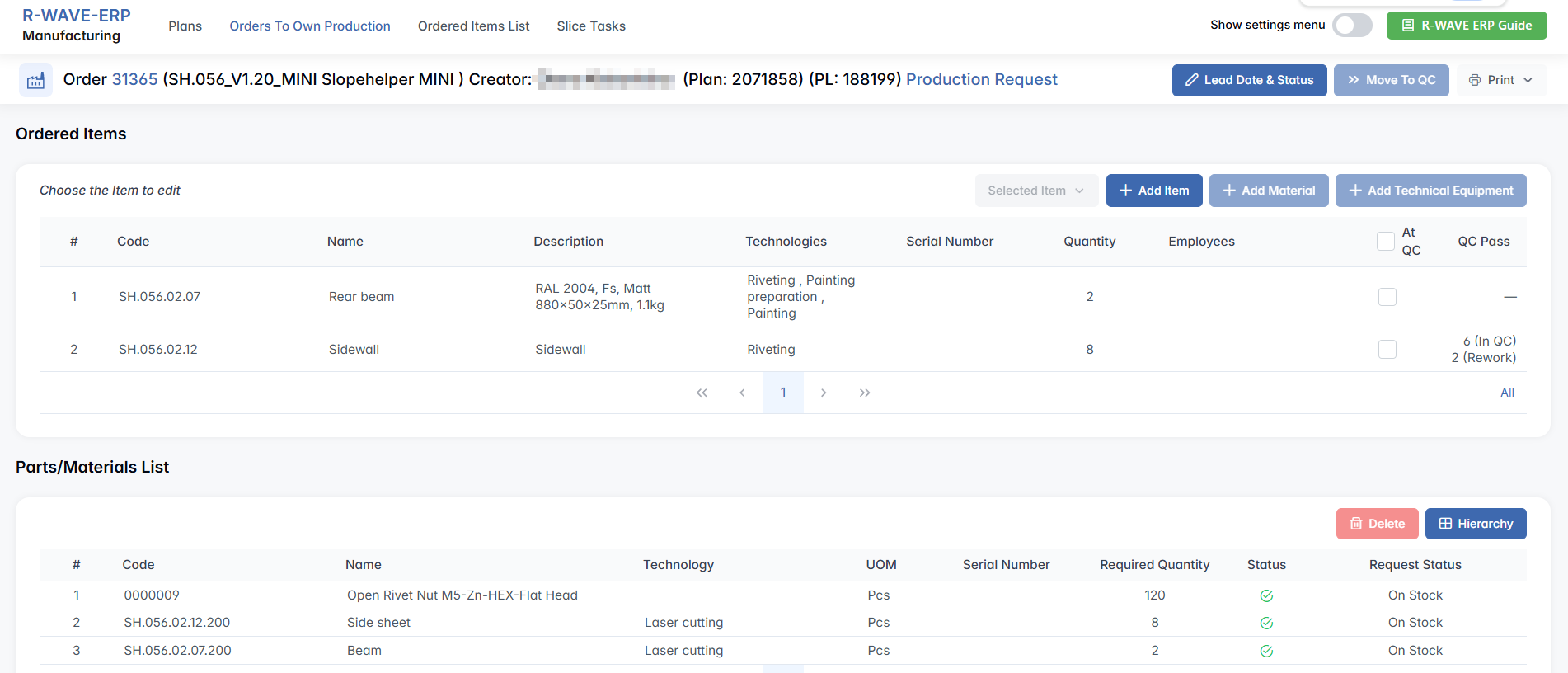

Order Details Page

To enter the detailed view of an order, you need to click Selected Order (Active when a row is selected) – Opens two options:

- Open Order – Opens the detailed order view.

- Remove – Deletes the order.

To view or manage a specific order, the user must select a row and click Own Production Items. This opens the detailed Order page.

At the top of the page, a Production Request is available. Clicking it opens the corresponding material request for the warehouse, allowing quick access to what resources are needed or have already been prepared.

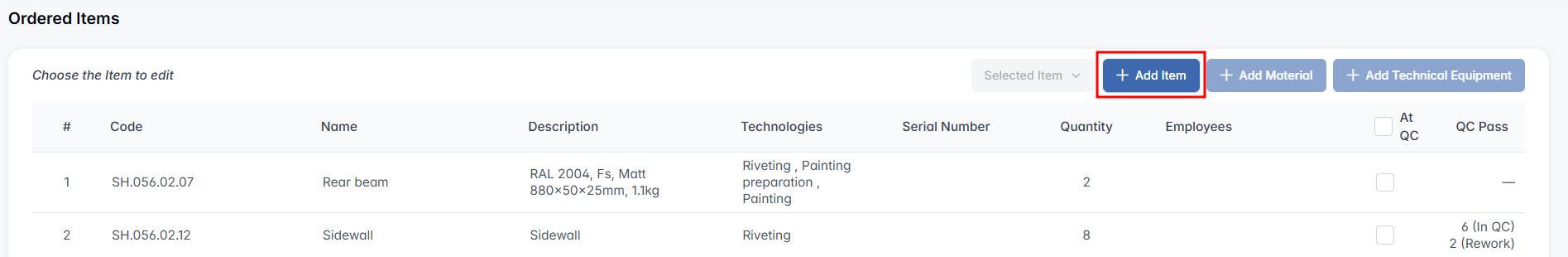

Ordered Items

Displays all items included in the order. Users can:

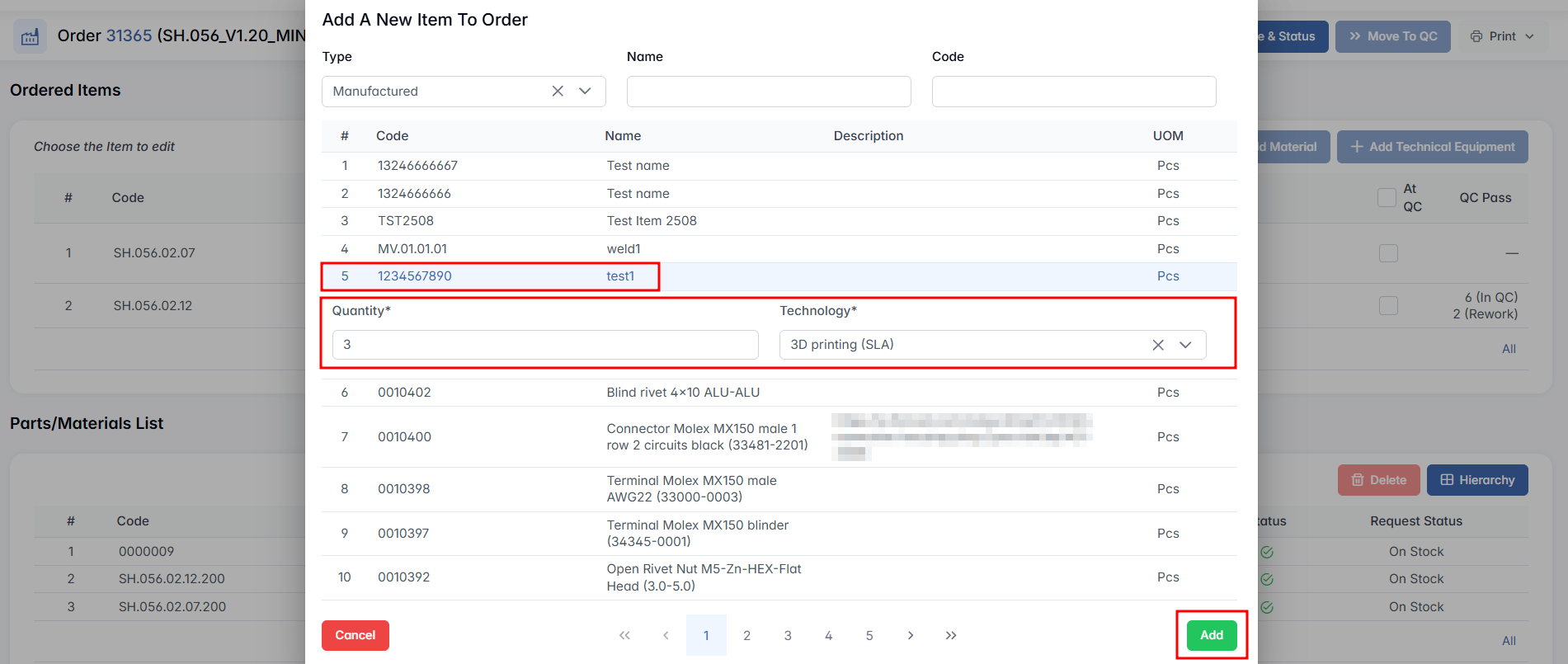

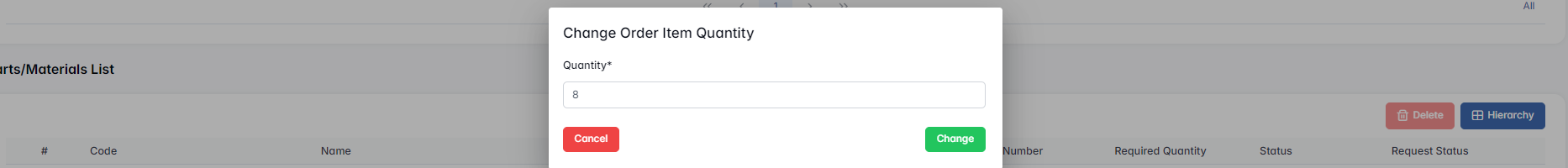

- Click Add Item to include new items in the order.

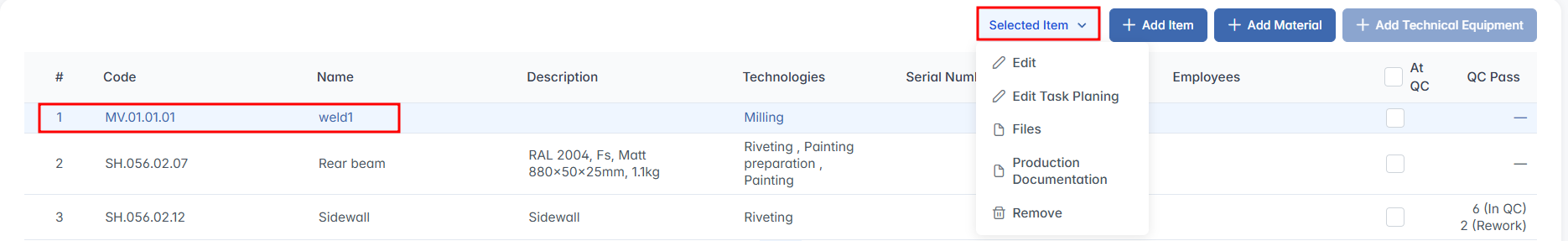

- Select an item row to activate the following actions under Selected Items:

- Add Material – Add extra parts/materials required for this ordered item;

This feature allows users to link warehouse materials to specific ordered items, indicating what internal components or parts will be supplied by the company rather than sourced externally.

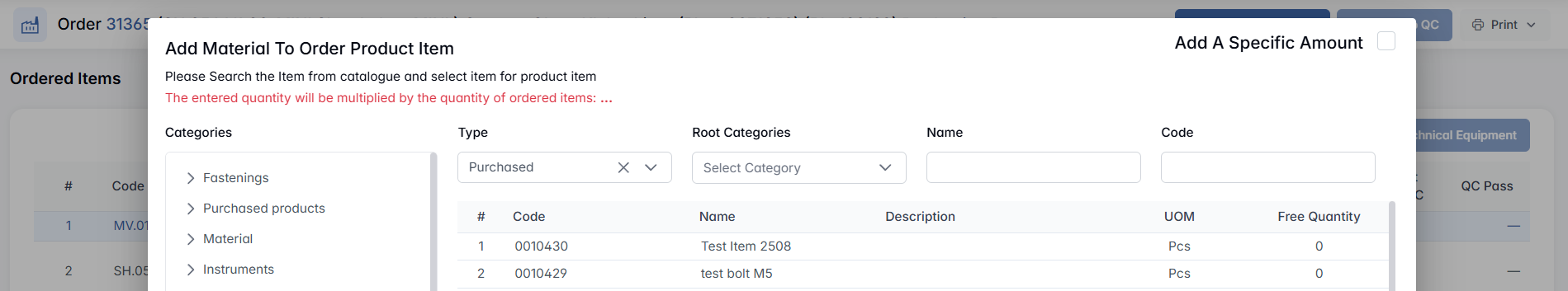

Clicking + Add Material opens a modal window:

- Add a specific amount – This checkbox allows the user to assign a fixed amount of material, regardless of the quantity of ordered items. If left unchecked, the entered quantity will be multiplied by the number of ordered items.

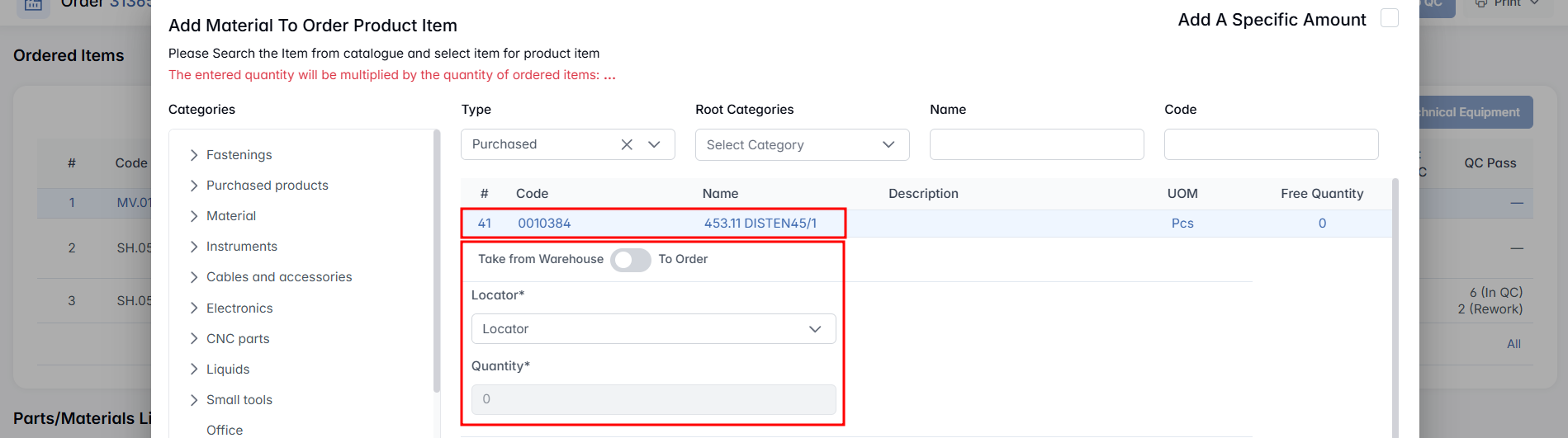

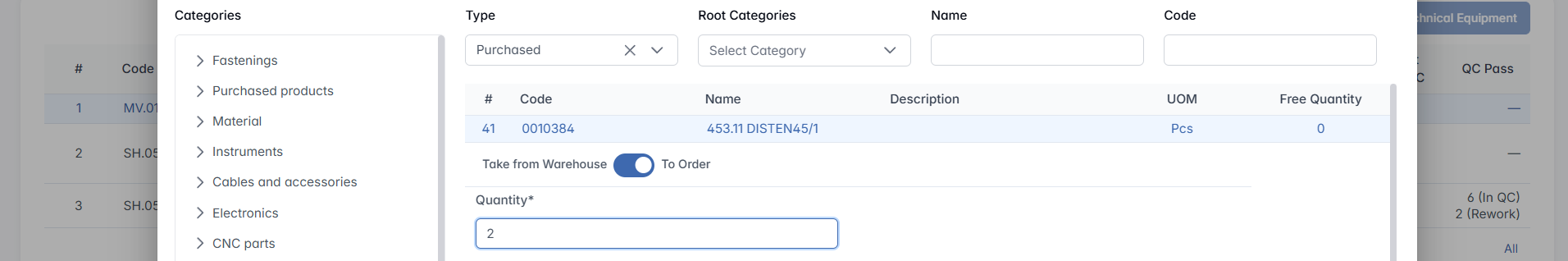

Search the item from catalog (filters: Category, Type, Root Category, Name, Code). If a material is available:

- Locator* field appears if Take from Warehouse is selected.

- Quantity* field is always required.

Important: Items with NEW status cannot be selected.

Take from Warehouse / To Order – This toggle lets the user choose whether to take the material directly from the warehouse (if it is currently in stock) or to request it through procurement (if it is not available). When set to To Order, the request will be forwarded to the procurement department to initiate the purchase of the material. Once the material is delivered to the warehouse, it will be automatically assigned to the corresponding order.

Click Add to confirm your choice.

- Add Technical Equipment – Adds technical equipment (TE) to the production task. This button is available only for items that have predefined TE assigned for a specific process.

If you need to assign TE to an item that does not yet have it:

- Go to Warehouse > Items.

- Select the item and click Edit Item.

- Enable the checkbox Required Technical Equipment.

- Assign the necessary equipment for the corresponding technology.

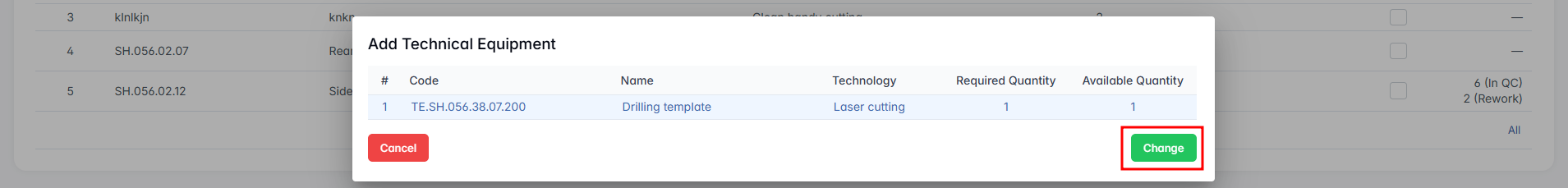

When you click Add Technical Equipment:

- If no equipment is currently available in the warehouse, the system will display No Records Found.

- If equipment is in stock, it will appear in a modal window where you can select and add it.

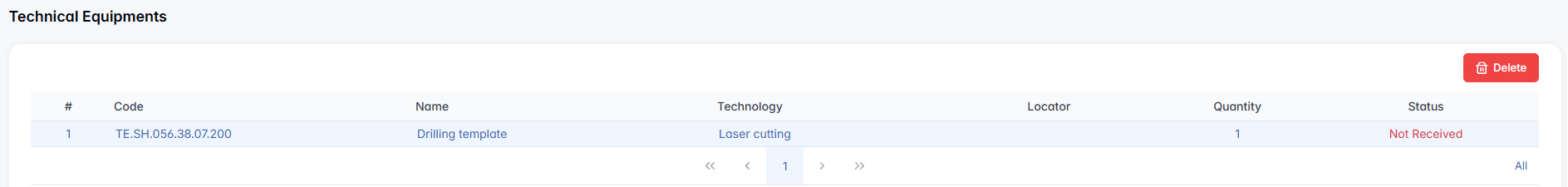

Once added, the required TE will appear in the Technical Equipment section below. This section lists key details such as Code, Name, Technology, Locator, Quantity, and Status. From here, you can also remove the equipment if necessary.

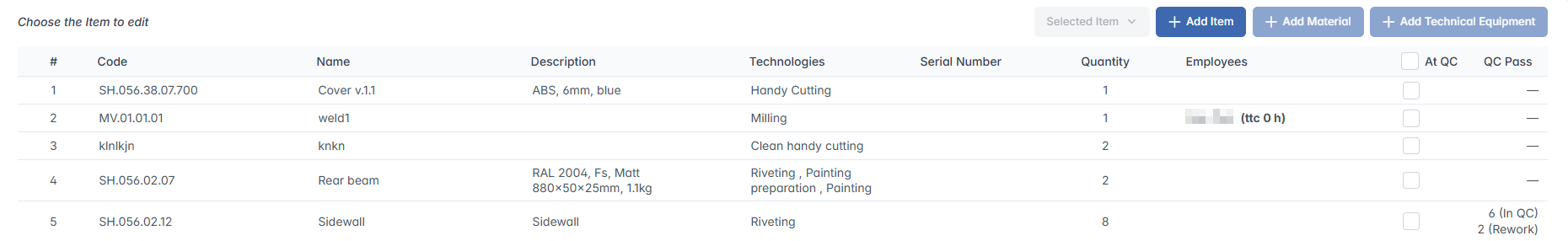

Ordered Items Overview

The Ordered Items Overview section displays detailed information about items included in the production task. Each row represents an item with the following attributes:

- Code / Name – Shows the unique identification code and the name of the item.

- Description – Provides additional specification details for the item.

- Technologies – Lists the technologies required for producing the item.

- Serial Number – Displays the serial number if the item requires serial tracking.

- Quantity – Indicates the number of items to be produced.

- Employees – Shows the personnel assigned to work on this item.

- At QC / QC Pass – Tracks the item’s progress through quality control.

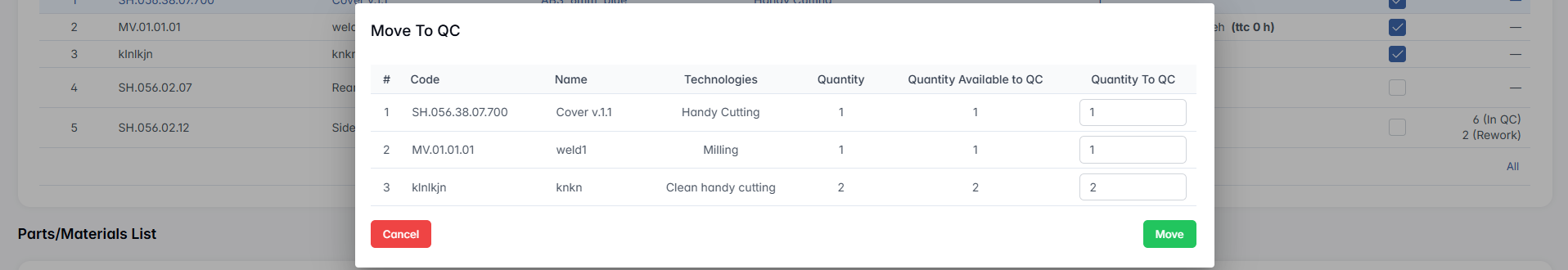

To move items to quality control, select the checkbox in the At QC column and click the Move to QC button that appears in the upper-right corner.

Ordered Items List

Ordered Items List

The Ordered Items List tab provides a comprehensive view of all individual items that are scheduled for production across different orders.

- Review item-level details across multiple orders;

- Identify which items are missing materials;

- Group selected items into a new merged ordered items;

- Apply filters based on product type, technology, or production status.

Purpose of the Ordered Items List Tab

This tab is designed to provide a clear and manageable view of every item scheduled for production. It helps users monitor individual production items, identify material shortages early, and optimize production planning by enabling merging of items into fewer orders, improving workflow efficiency.

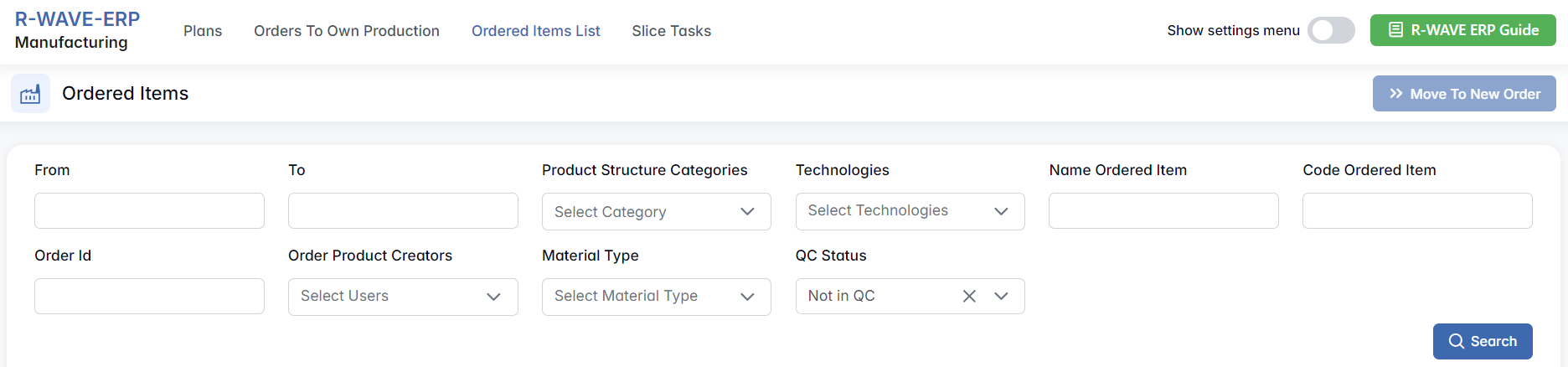

Filter Panel

At the top of the page is a Filter Panel, which allows the user to narrow down the list of ordered items based on various criteria.

- From / To – Filter by the item’s order creation date range;

- Product Structure Categories – Select relevant product structure categories;

- Technologies / Select Technologies – Multi-select list to filter by production technologies (e.g. Laser Cutting, Milling, Painting);

- Name Ordered Item – Search by item name;

- Code Ordered Item – Search by item code;

- Order ID – Enter the order number directly;

- Order Product Creators / Select Users – Filter by users who created the original order;

- Material Type / Select Material Type – Multi-select filter for material types;

- QC Status – Filter by current QC status;

At the end of the panel, a Search button applies all selected filters.

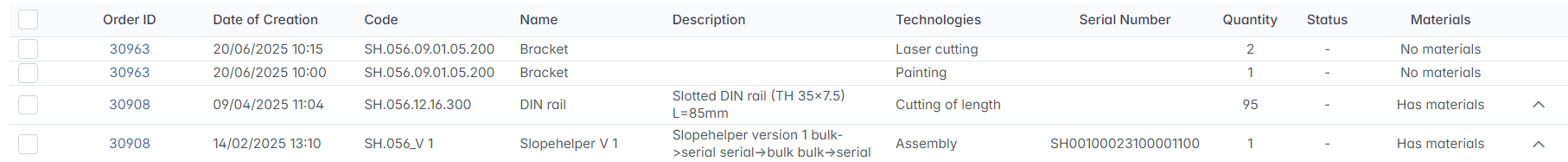

Ordered Items Table

Below the filters, a table displays all matching items. Each row represents a single item scheduled for production and includes all relevant data. A checkbox appears at the beginning of each row, allowing the user to select one or more items.

- Order ID – Each value in this column is clickable, allowing the user to open the full order page (see previous section for details).

Expand Record – Each production record can be expanded to display the list of related materials. To do this, click the arrow icon (▾) on the right-hand side of the row.

When expanded, the section shows details such as: Code and Name of each material, Technology (if assigned), UOM (Unit of Measure), Serial Number (if applicable), Required Quantity, Status, Request Status (e.g., On Stock). This view allows users to verify whether all necessary materials are available for the task.

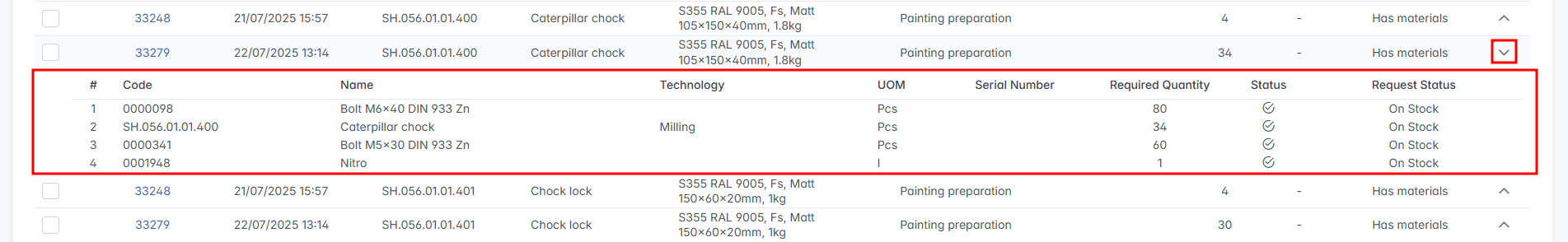

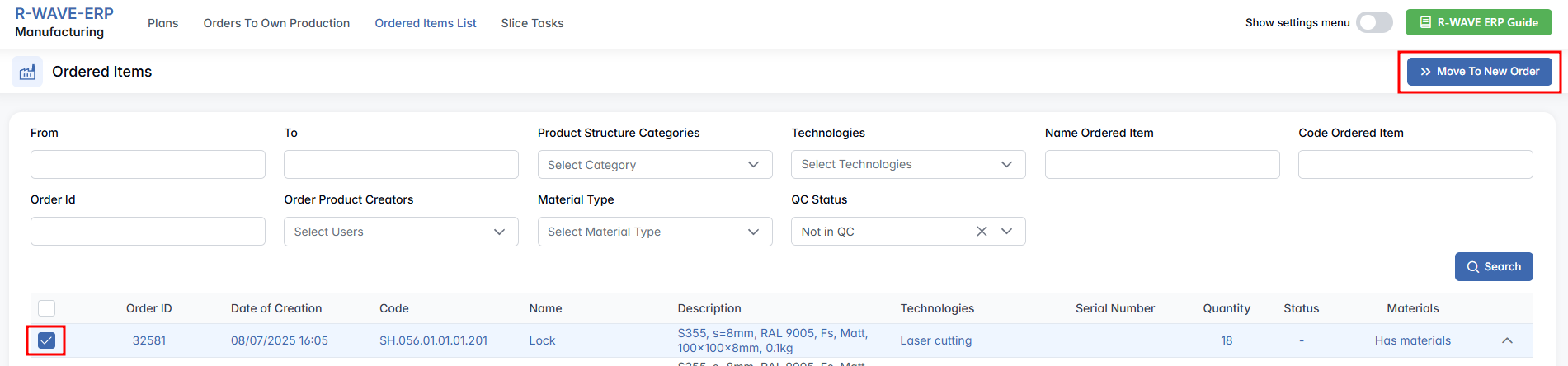

Move to New Order

When at least one row is selected, a Move To New Order button appears in the top right corner of the page. Clicking this button merges all selected items into a new production order.

The system will automatically redirect the user to the newly created Order #number page (as described in detail in the previous tab: Orders to Own Production).

This functionality allows for efficient grouping of scattered ordered items into a consolidated batch for production.

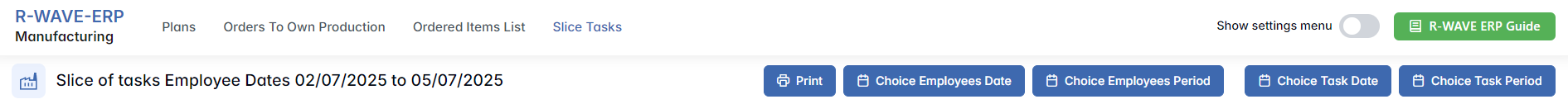

Slice Task

Slice Task

The Slice Task page provides a detailed overview of production tasks scheduled for a specific date or period. This tab is especially useful to monitor task assignments, track employee workload, and assess machine utilization.

Purpose of the Slice Task Tab

This tab allows you to manage and monitor detailed production tasks by providing a clear view of task assignments, schedules, and statuses.

- Task Planning and Assignment

Employees assigned to tasks during production planning appear here, enabling easy tracking of who is responsible for each task.

- Filtering and Sorting

Quickly locate tasks by filtering for specific employees, statuses, technologies, or production list origins. You can also sort tasks by employee or machine durations to balance workloads efficiently.

- Monitoring Status

Easily see the current status of tasks to identify which are on schedule (Ordered) and which face delays or material shortages (Deficit).

Action Buttons

At the top of the page, you will find several important buttons to customize the displayed data:

- Print – Prints the current view of the slice tasks list.

- Choice Employees Date – Opens a calendar to select a specific day to view tasks assigned to employees on that day.

- Choice Employees Period – Opens a dialog to select a start and end date, showing tasks assigned to employees within that period.

- Choice Task Date – Opens a calendar to select a specific day to view all tasks scheduled for that day.

- Choice Task Period – Opens a dialog to select a start and end date, displaying all tasks scheduled within that time frame.

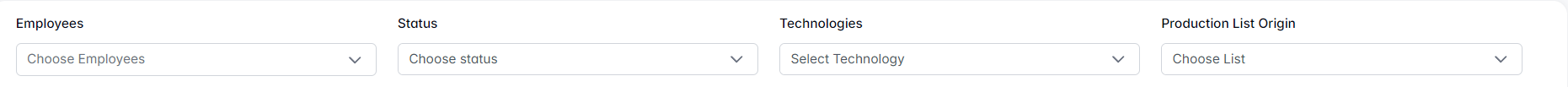

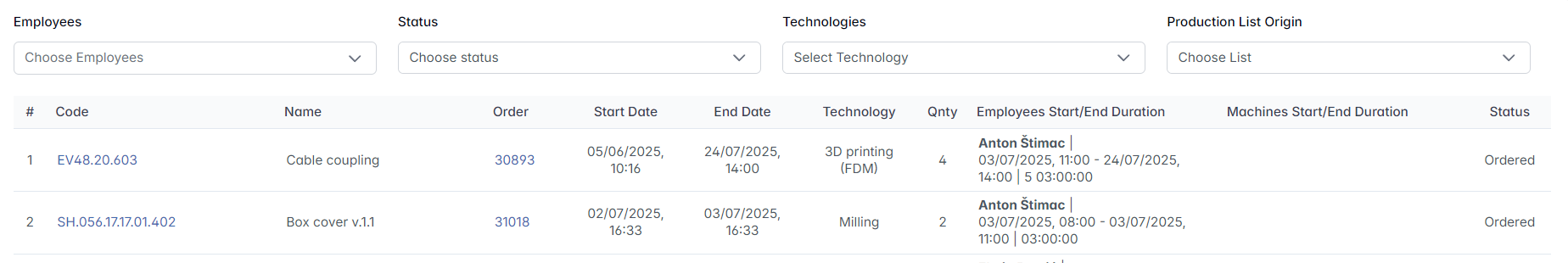

Filter Tab

Below the header buttons is the Filter Tab, allowing you to narrow down the list of tasks by several criteria:

- Employees / Choose Employees – Multi-select dropdown to filter tasks assigned to one or more employees.

- Status – Filter tasks by their current status (e.g., Ordered, Deficit, Completed).

- Technologies – Filter by the production technology or process used for the task (e.g., Assembly, Cable assembly).

- Production List Origin – Filter tasks based on the origin production list associated with the task.

Slice Tasks Table

The main part of the page is a table that lists all production tasks matching the selected filters. Each row corresponds to a single task or work slice.

- Code – Item code with version (e.g., AH.01_V1.10).

- Name – Item name or description.

- Order – Production order ID linked to the task.

- Start Date – When the task is scheduled to start (date and time).

- End Date – When the task is scheduled to finish (date and time).

- Technology – Technology or production process involved.

- Qnty – Quantity of items to be produced in this task.

- Employees – Employees assigned to perform this specific task.

- Start/End Duration (Employees) – Duration employees are assigned to the task. Clicking this column toggles sorting (ascending/descending).

- Machines – Machines assigned to perform this specific task.

- Start/End Duration (Machines) – Duration machines are scheduled for the task. Clicking this column toggles sorting (ascending/descending).

- Status – Current task status (e.g., Ordered, Deficit).

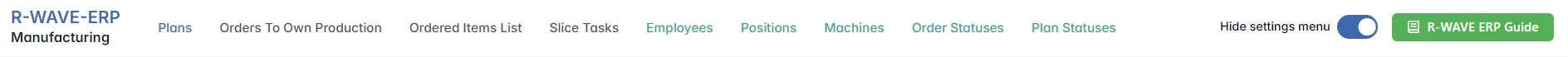

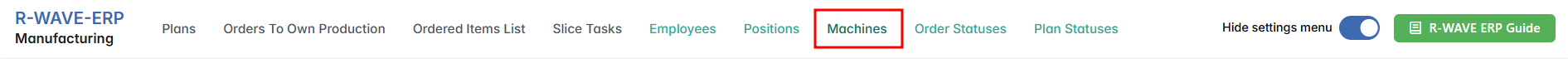

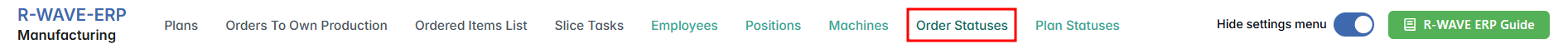

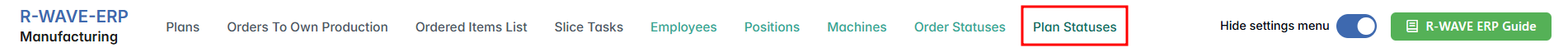

Hidden Settings in the Manufacturing Module

Hidden Settings in the Manufacturing Module

The Manufacturing module includes a Hidden Settings Menu, which can be accessed by enabling the Show settings menu toggle switch located in the top-right corner of the screen.

Once activated, four additional configuration tabs become visible:

- Employees

- Positions

- Machines

- Order Statuses

- Plan Statuses

These settings allow you to configure and manage key production parameters, ensuring accurate task assignments, consistent status tracking, and organized resource data throughout all manufacturing operations.

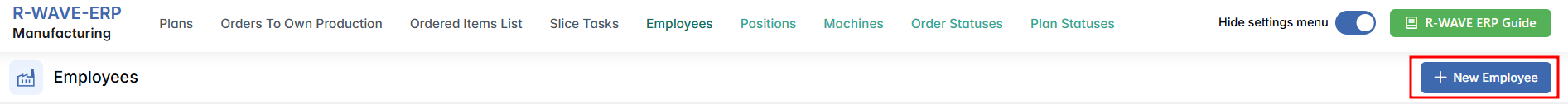

Employees

This tab allows you to manage the list of employees involved in manufacturing tasks. You can create new employee records, edit existing ones, or remove entries.

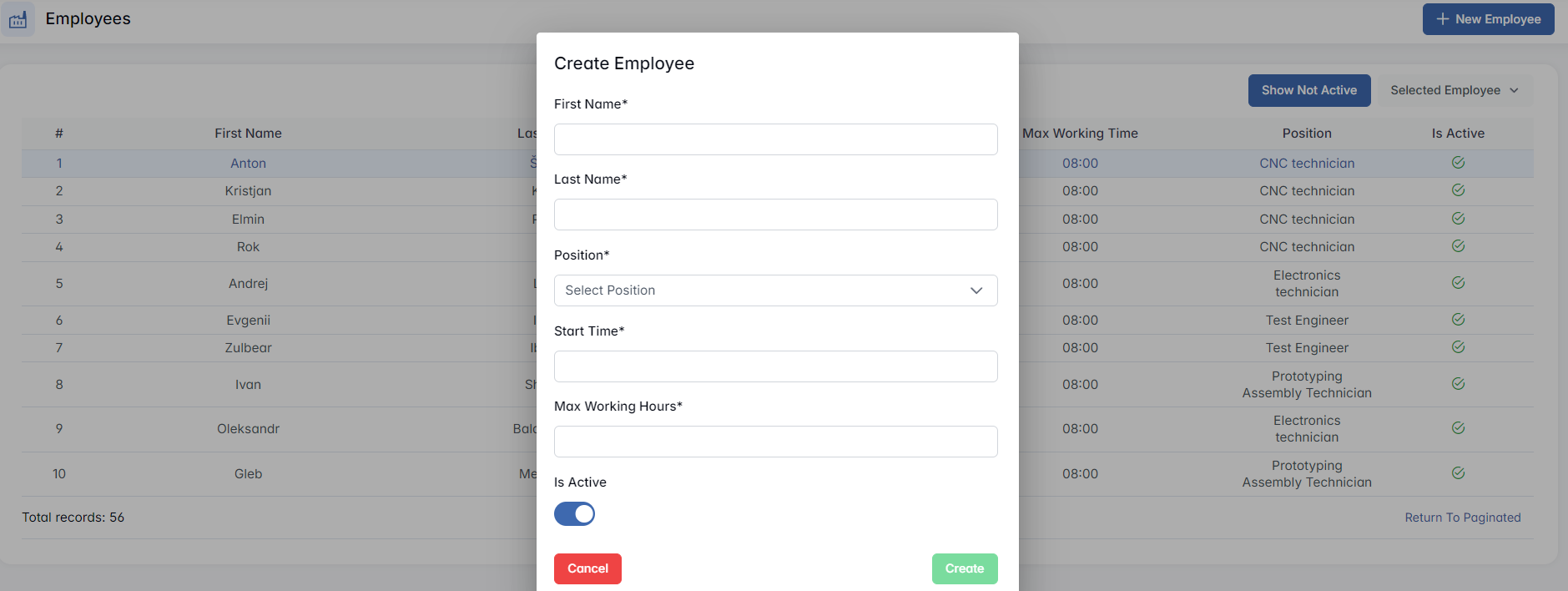

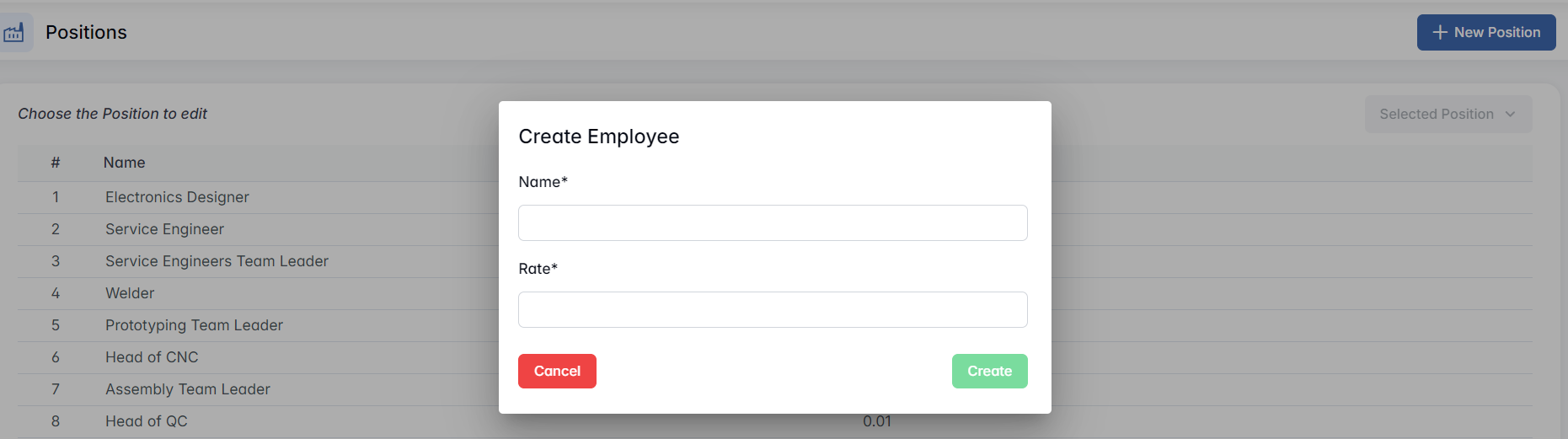

Creating a New Employee

Click the + New Employee button to open the creation form. Fill in the required fields:

- First/Last Name* – first/last name of the employee

- Position* – assigned role or job title within the manufacturing process

- Start Time* – when the machine's workday begins (e.g., 08:00)

- Max Working Hours* – total daily working time (e.g., 8)

- Is Active – toggle switch to indicate whether the employee is currently active in the system

Click Create to save the new employee record.

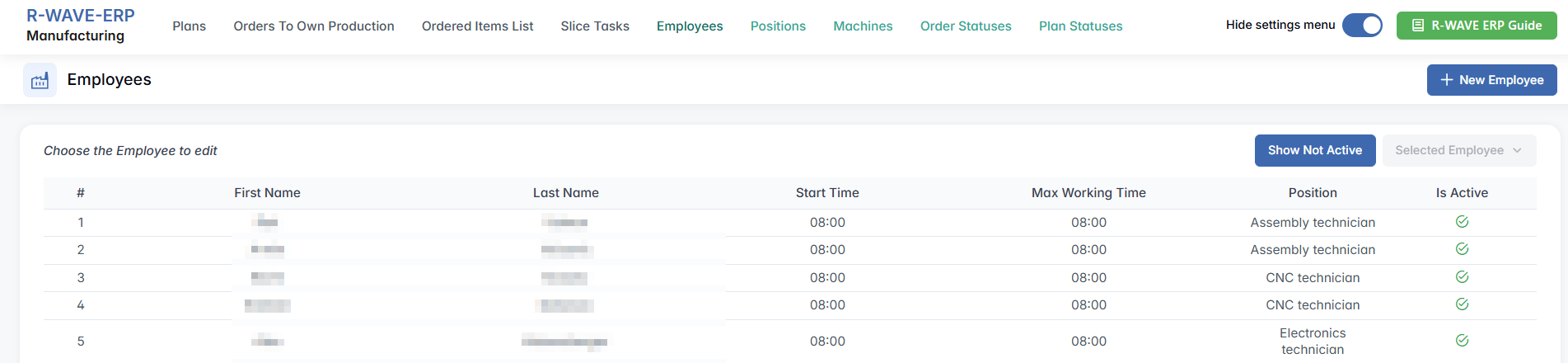

Employee Table

Below the form is a table displaying all active employees, showing the following columns:

To view inactive employees, click the Show Not Active button beneath the table. This button then toggles to Show Active, allowing you to switch views.

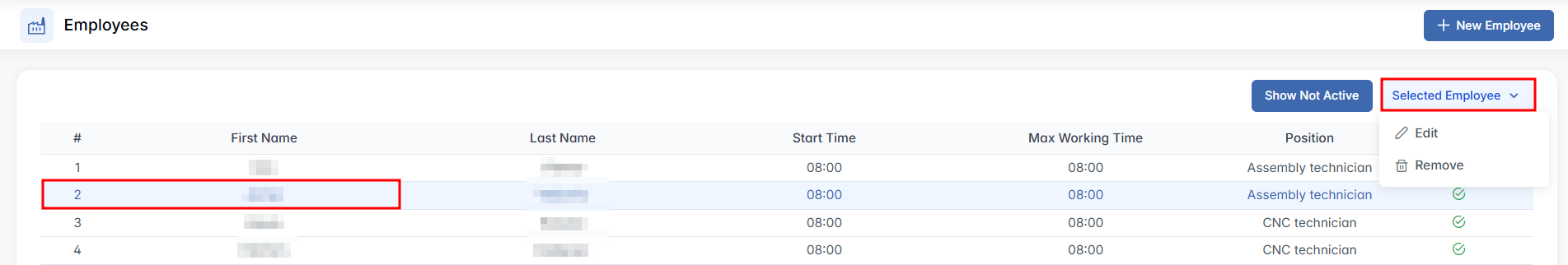

Editing and Removing Employees

Select an employee from the table to activate the Selected Employee panel. Here, you can:

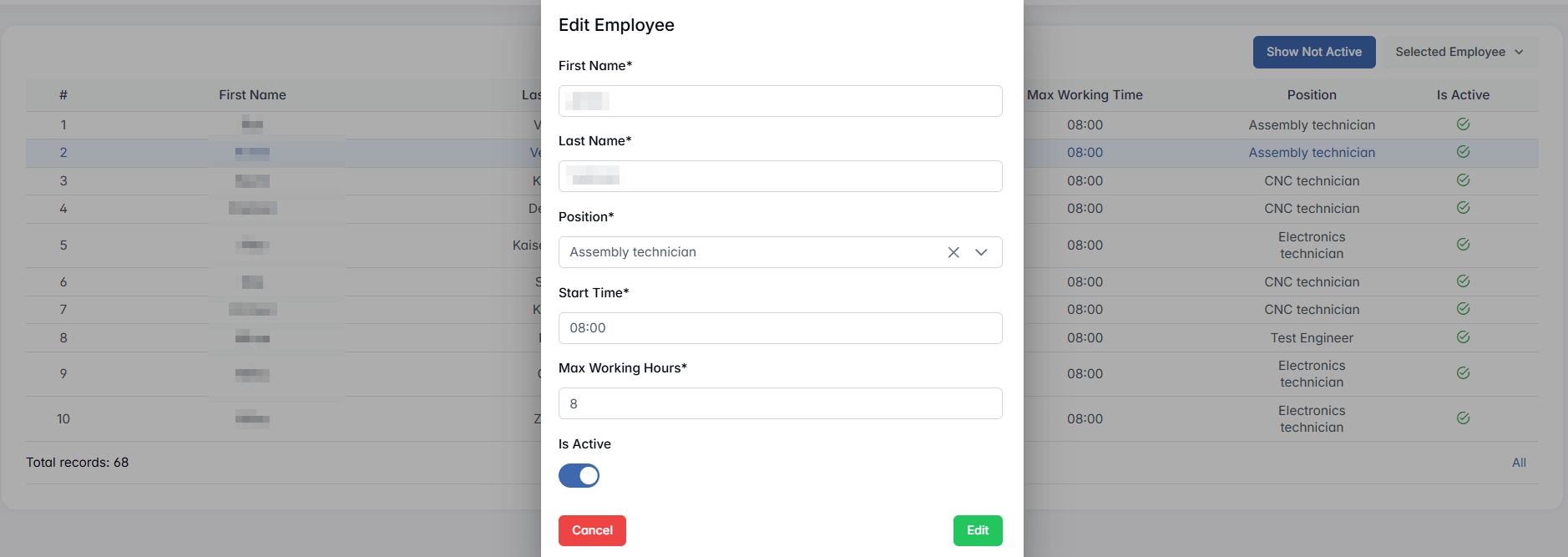

- Click Edit to update the employee’s information

- Click Remove to delete the record

The Edit Employee form shows the same fields as the creation form and allows you to update the details, including activation status.

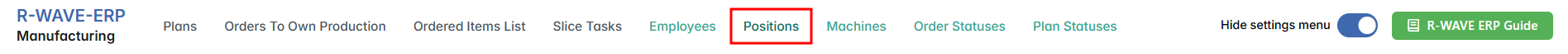

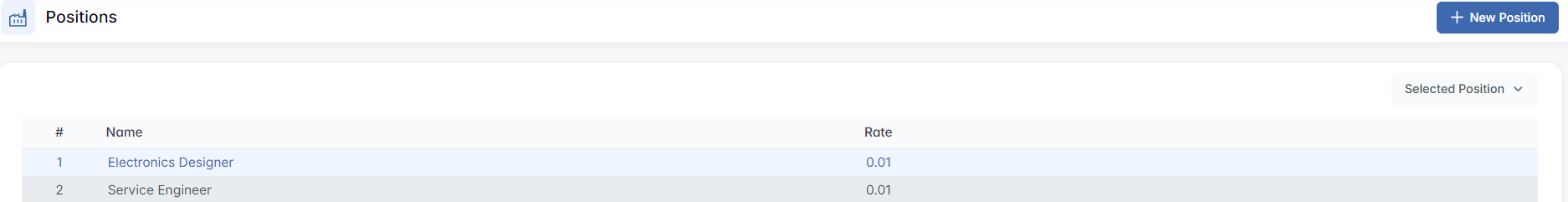

Positions

This tab is used to define and manage employee positions within the manufacturing environment. Each position has a name and an associated rate used for planning or cost evaluation purposes.

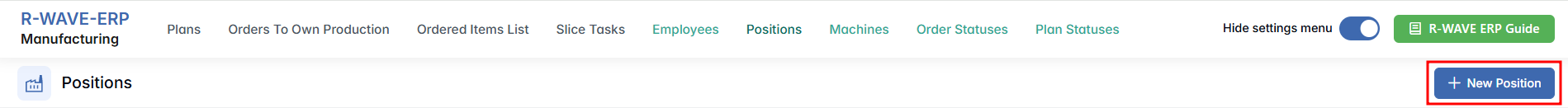

Creating a New Position

Click the + New Position button to open the creation form. Fill in the required fields:

- Name* – the title of the position (e.g., Service Engineer)

- Rate* – numerical value (e.g., 0.01) representing the hourly or cost rate

Click Create to save the position.

The table displays all created positions along with their assigned rates:

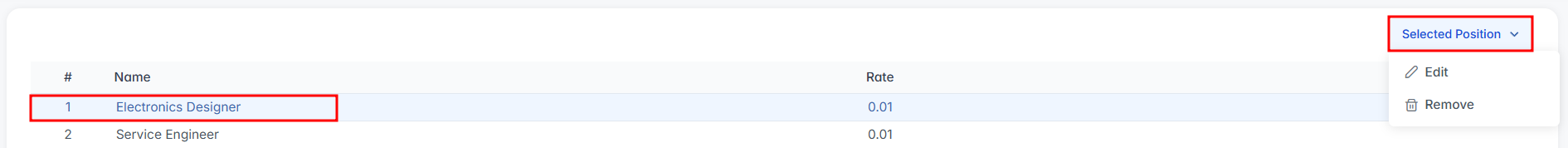

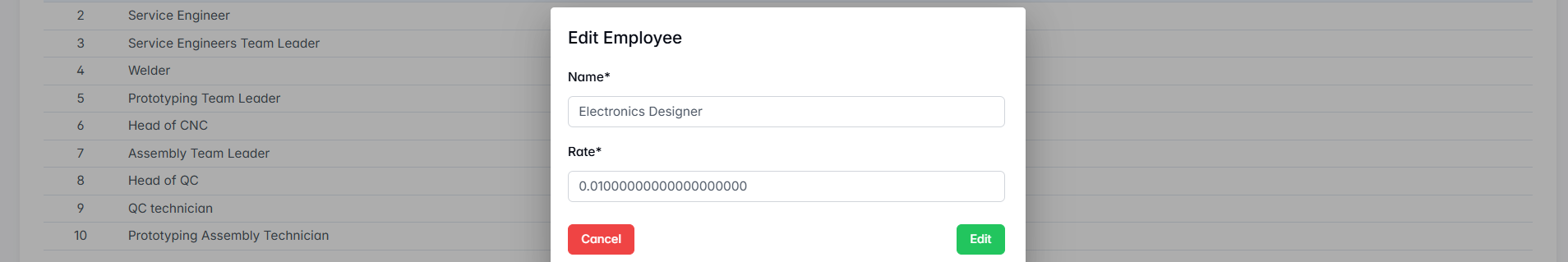

Editing and Removing Positions

Select any position from the table to activate the Selected Position button. Here, you can:

- Click Edit to update the position name or rate

- Click Remove to delete the position

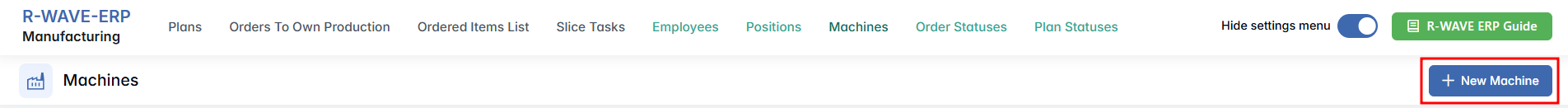

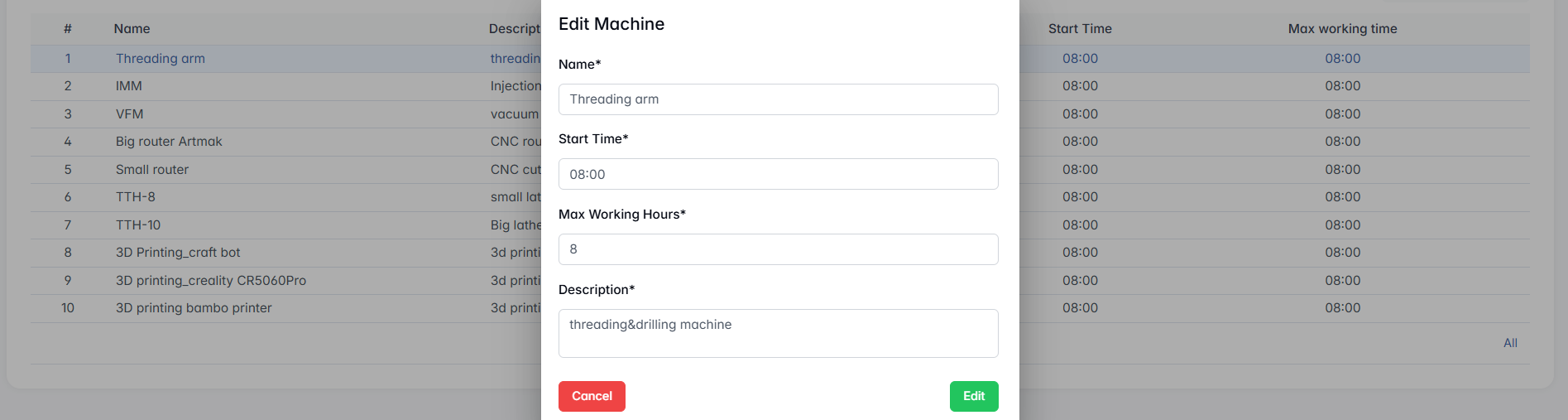

Machines

This tab allows you to manage the list of machines used in the manufacturing process, including their working schedules and descriptions. Proper configuration ensures accurate task scheduling and workload distribution.

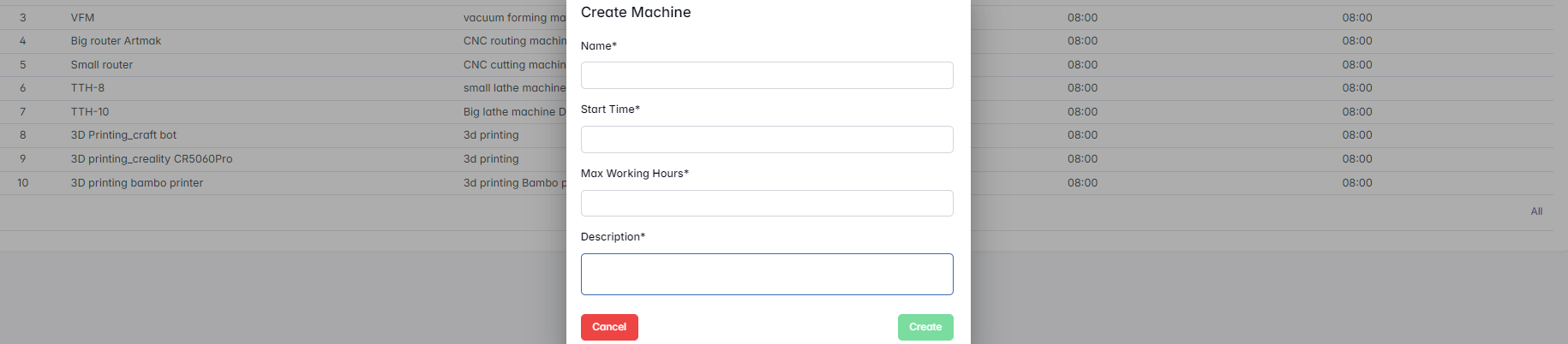

Creating a New Machine

Click the + New Machine button to open the creation form. Fill in the following required fields:

- Name* – name of the machine (e.g., IMM)

- Start Time* – when the machine's workday begins (e.g., 08:00)

- Max Working Hours* – total daily working time (e.g., 8)

- Description* – short description of the machine (e.g., Injection molding machine)

Click Create to save the new machine.

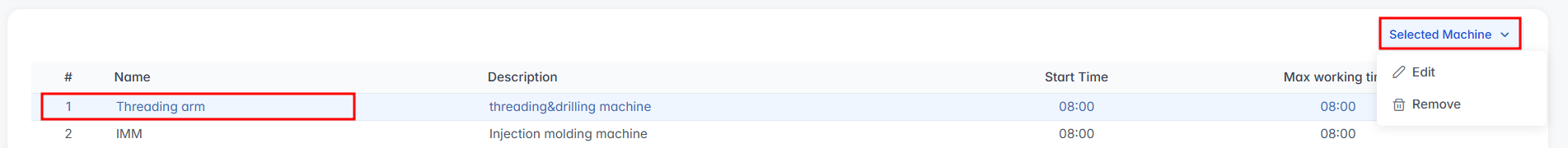

Editing and Removing Machines

Select a machine row to activate the Selected Machine panel, where you can:

- Click Edit to update the machine details

- Click Remove to delete the machine from the list

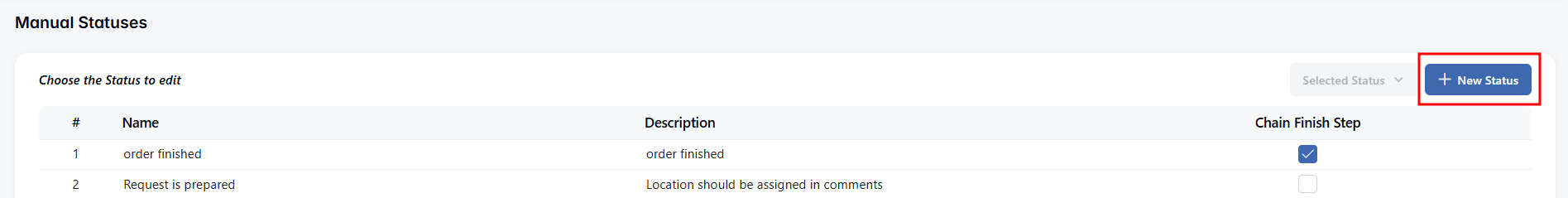

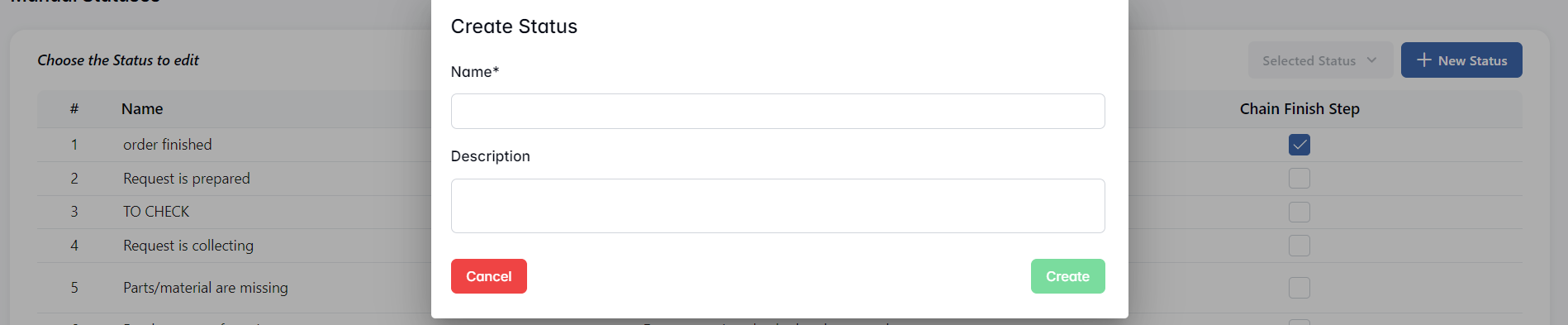

Order Statuses

This tab allows you to manage the manual and automatic statuses used to track production orders throughout their lifecycle. Well-defined statuses help ensure consistency in communication and task flow across the system.

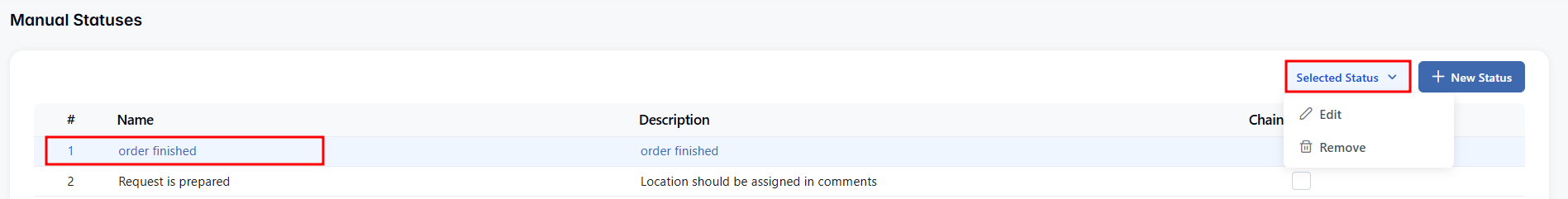

Manual Statuses

You can create, edit, or remove custom statuses that are manually assigned during the production process.

+ New Status – opens the creation form with the following fields:

- Name* – name of the status

- Description – additional explanation or instruction

Click Create to save the new status.

Selected Status – becomes active when a status is selected from the table, allowing you to:

- Edit the status details

- Remove the status from the list

Chain Finish Step – a checkbox indicating whether the status is considered a final step in the workflow

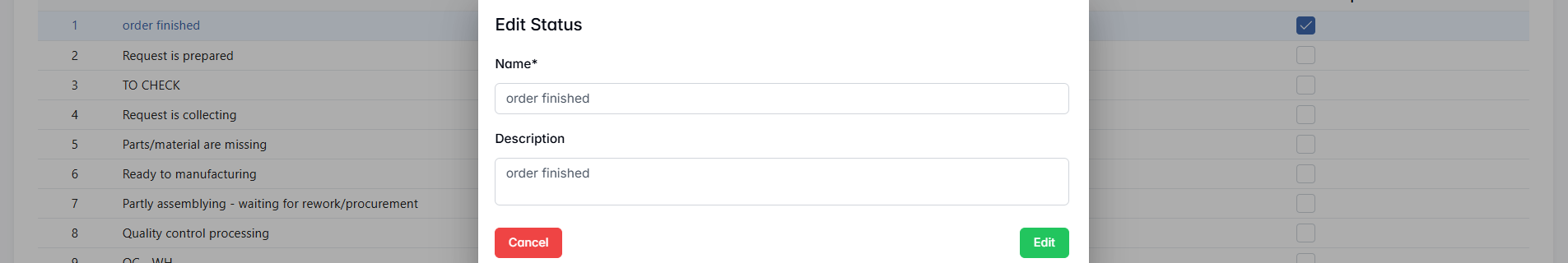

Automatic Statuses

These are system-generated statuses that reflect changes in production automatically. They can only be edited, not deleted or manually created.

Edit Status button becomes active upon row selection. By this button user can change the name of status.

Is Active – checkbox to enable/disable the status in the workflow

Chain Finish Step – a checkbox indicating whether the status is considered a final step in the workflow

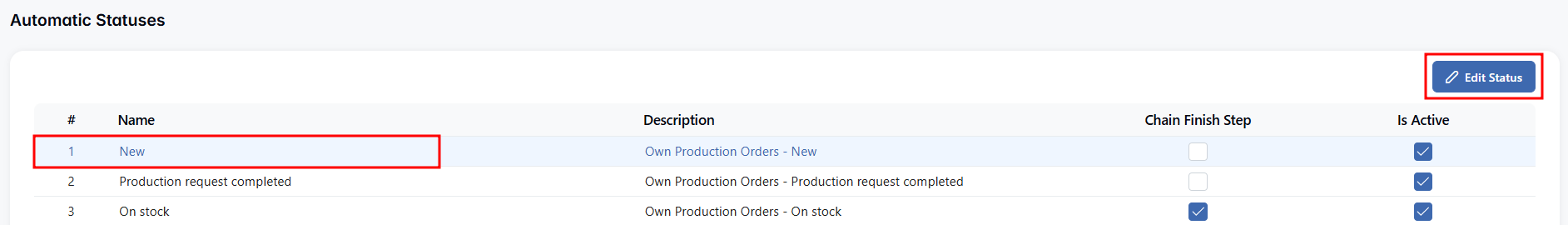

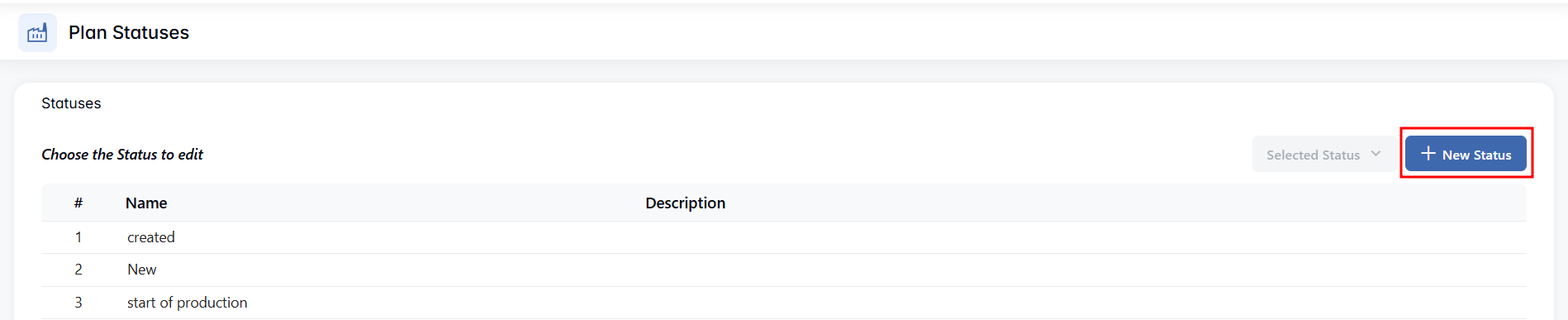

Plan Statuses

This tab allows you to manage the statuses used to track stages of production planning. These statuses help define and communicate progress throughout the planning workflow.

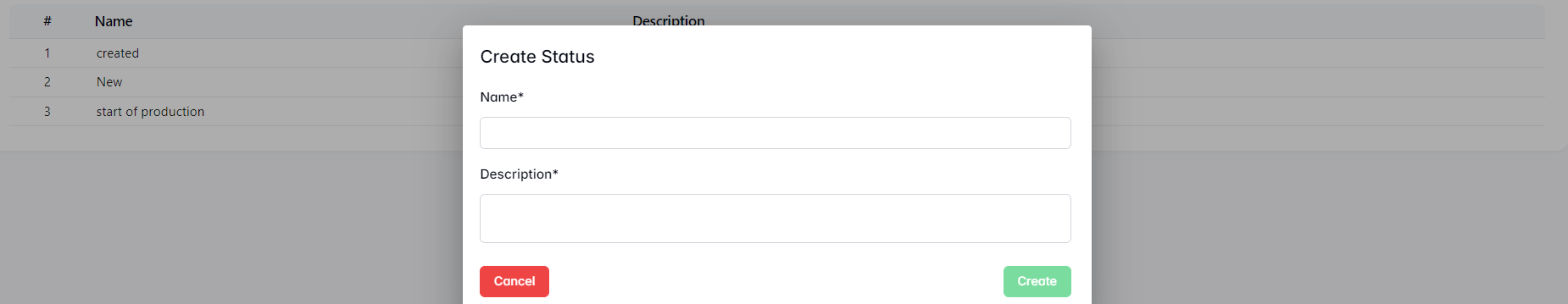

Creating New Plan Status

Click the + New Status button to open a form for adding a new status. The form includes:

- Name* – the status label (e.g., start of production)

- Description – optional details about how or when this status is used

Click Create to save the new status.

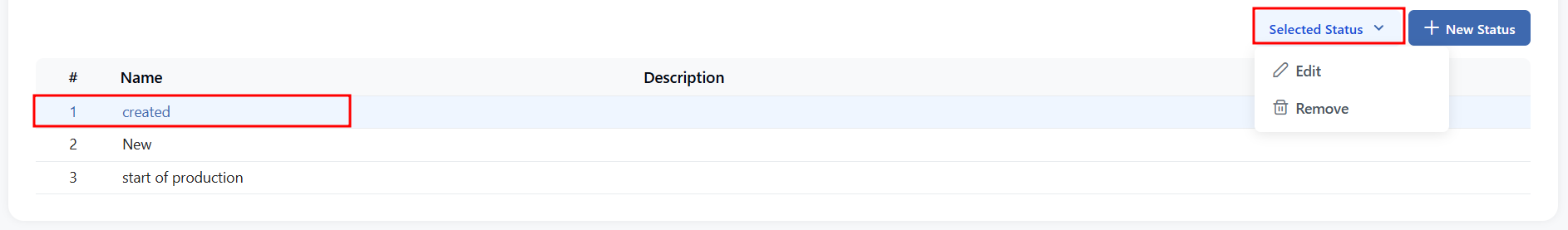

Managing Existing Statuses

Select a row in the table to activate the Selected Status button. This unlocks two actions:

- Edit – update the name or description

- Remove – delete the selected status from the list